-

Description

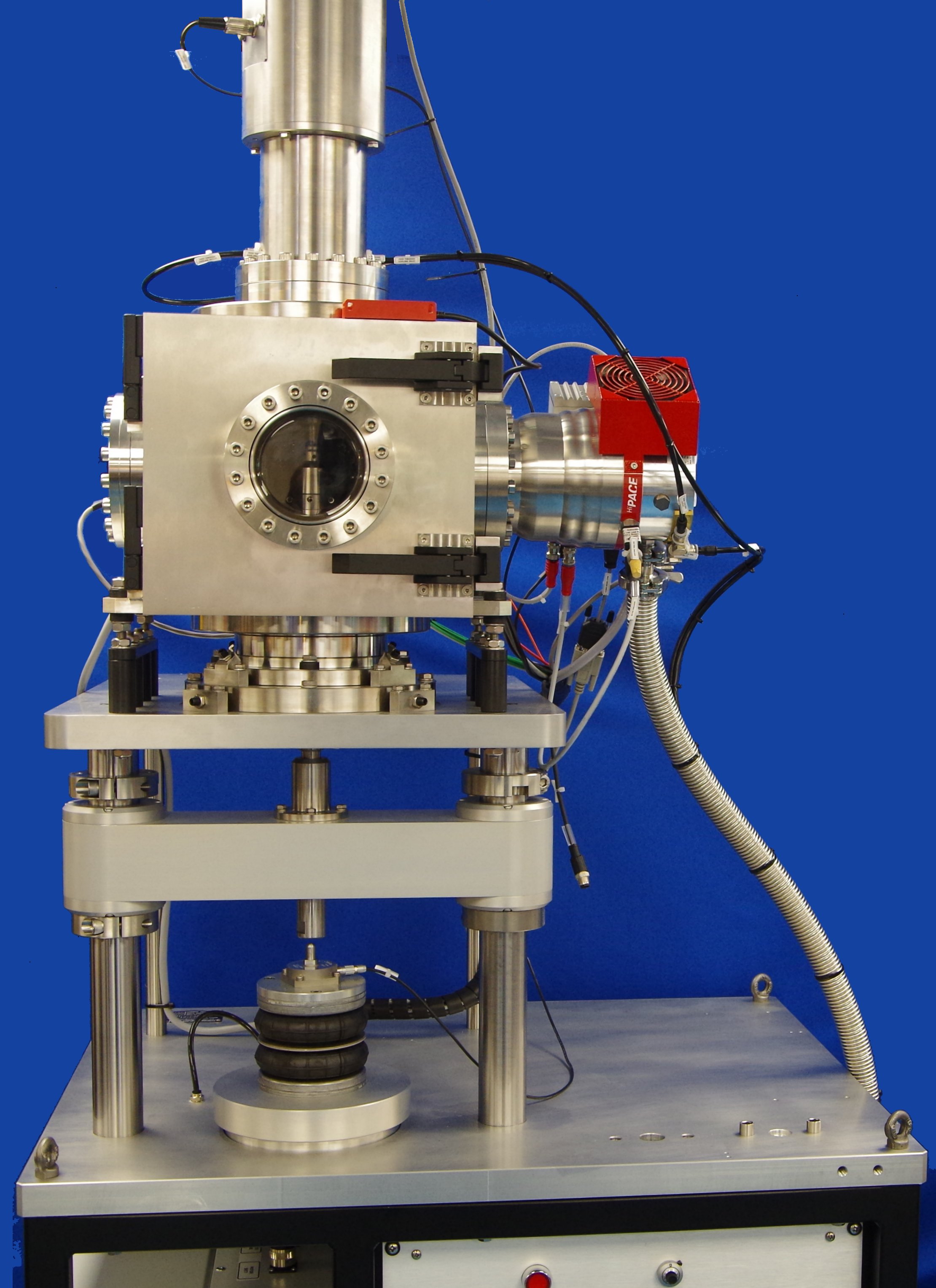

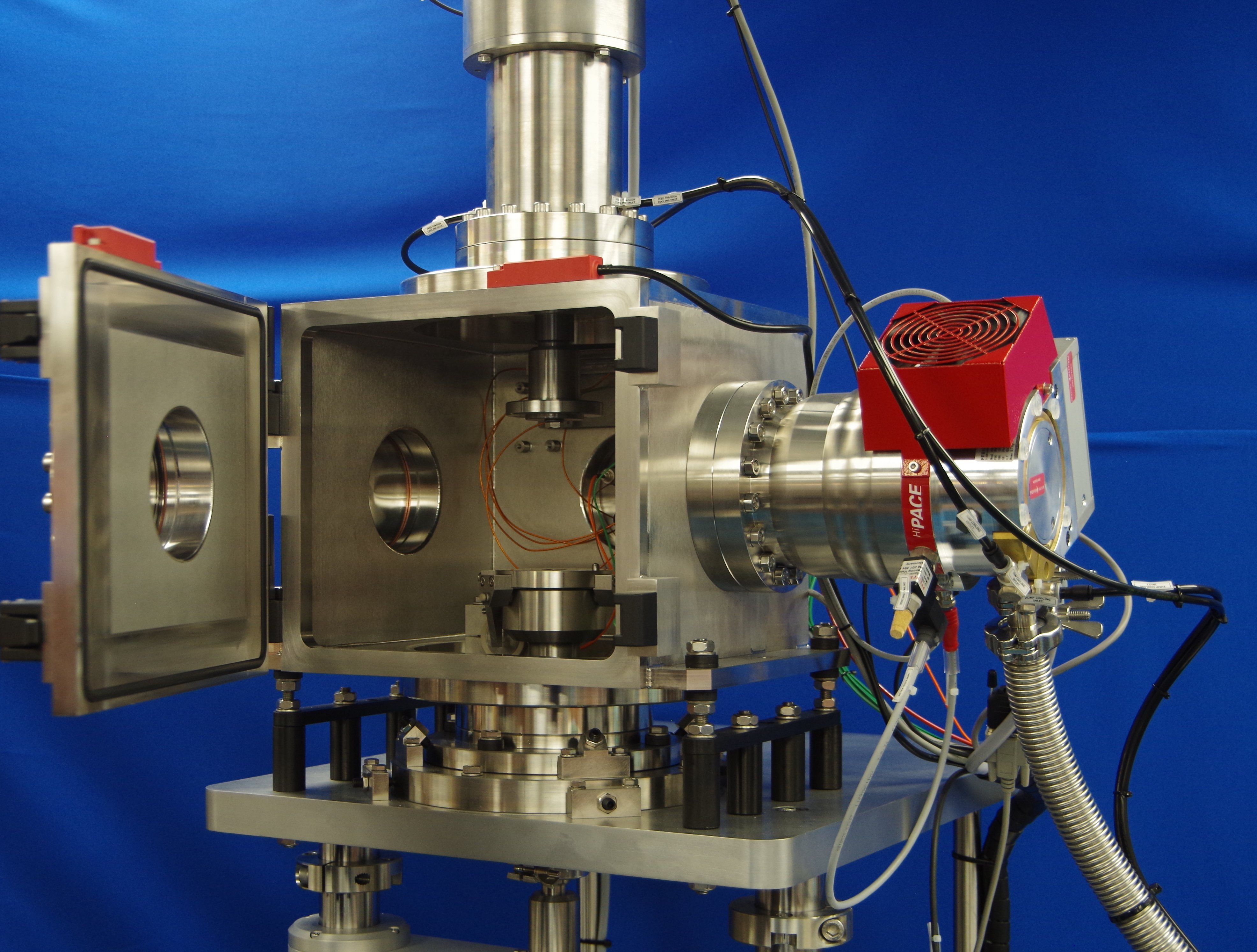

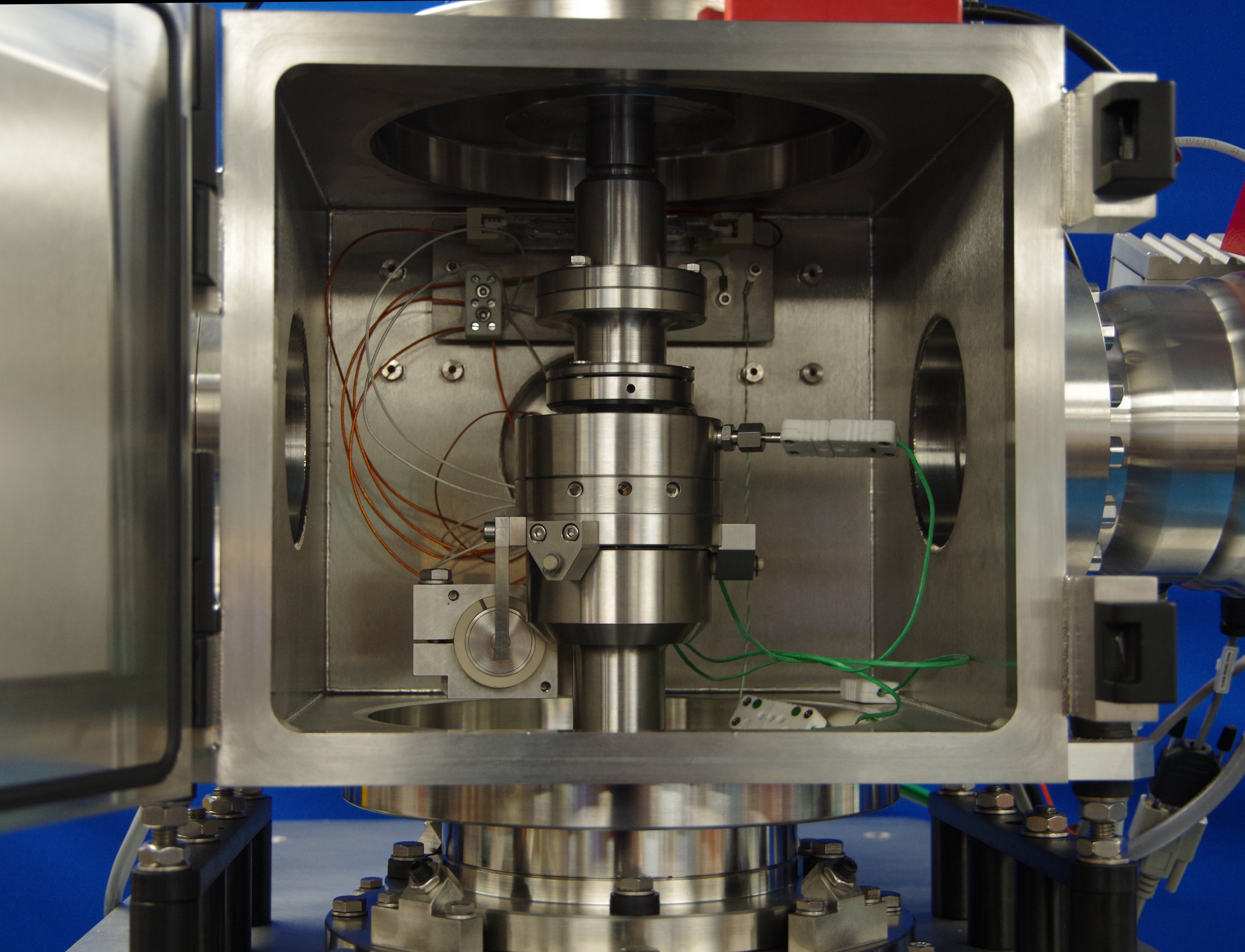

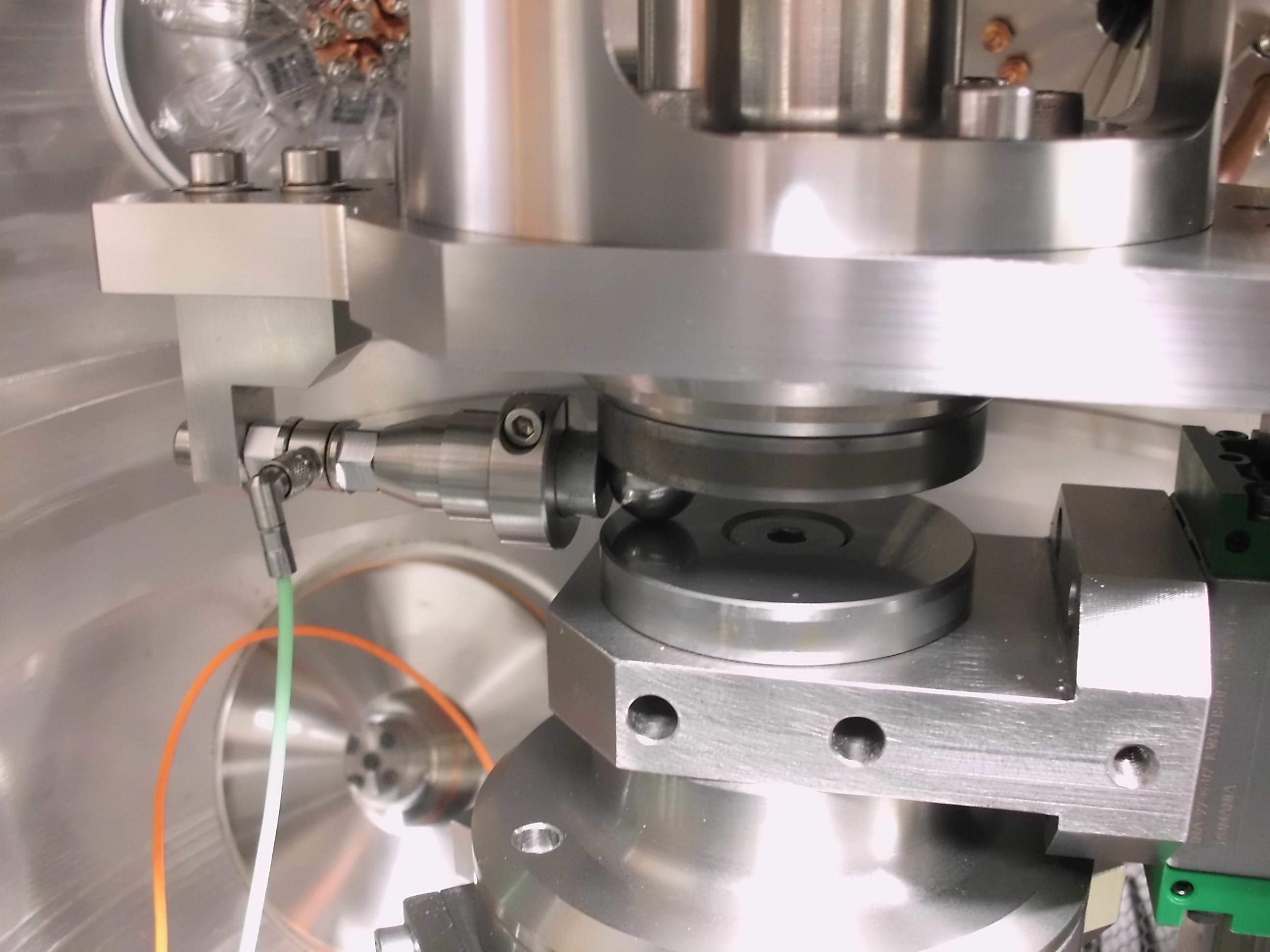

The TE 91 Precision Rotary Vacuum Tribometer is based on a bench mounted test chamber. A motor driven test spindle, in the form of standard rotary feedthrough, projects downwards into the chamber and carries tooling for mounting rotating test samples. A servo motor with encoder feedback provides a variable speed turn-down ratio of 100:1.

The various fixed specimen test adapters can be mounted on a mandrel projecting through the bottom of the chamber and coaxial with test spindle.

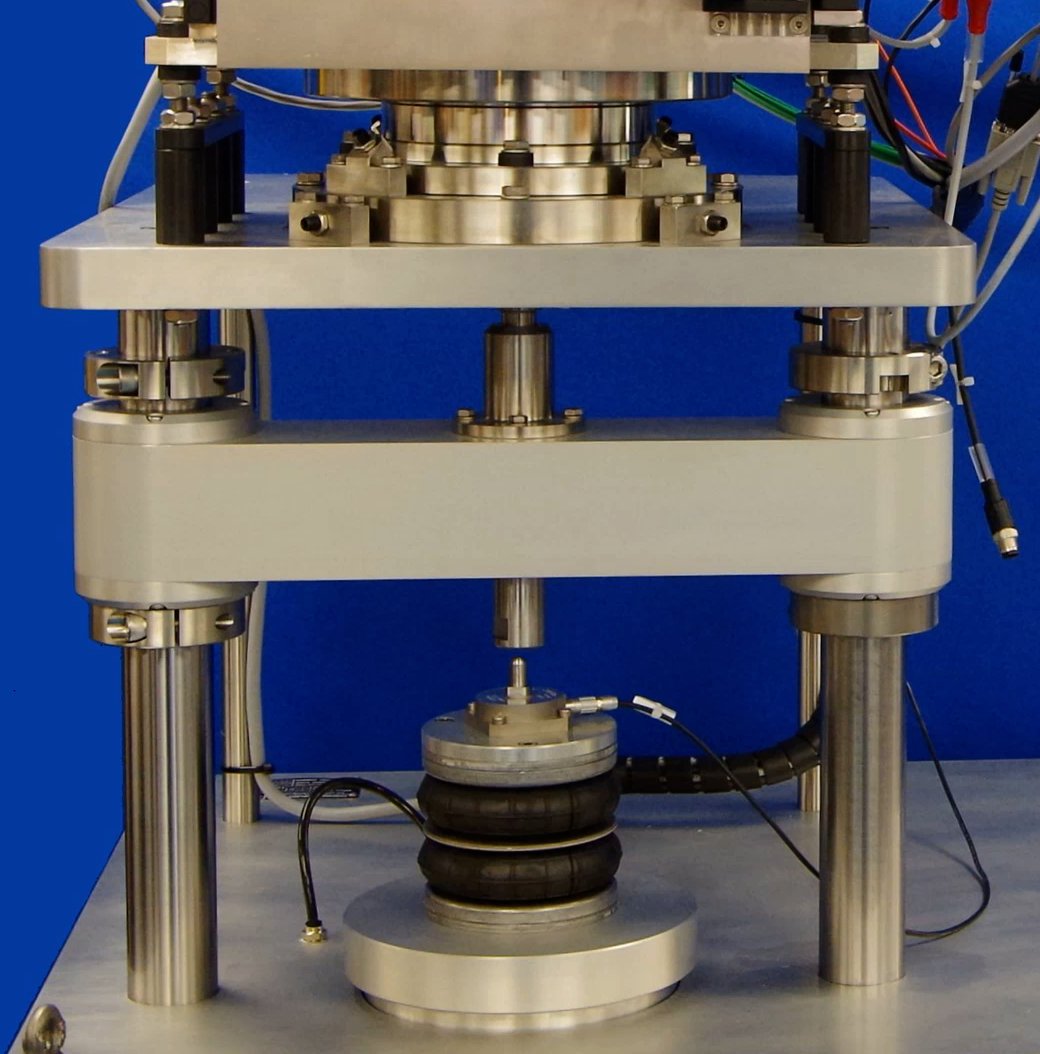

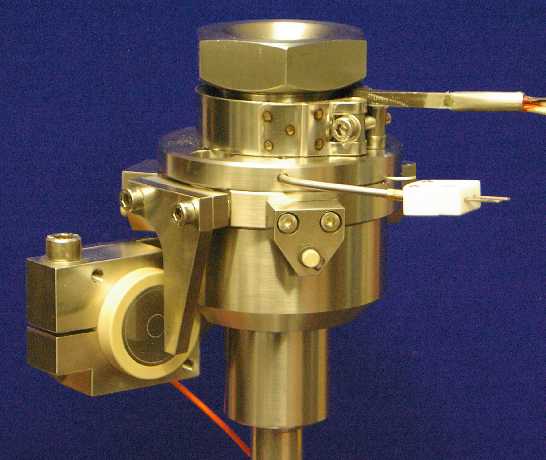

The mandrel is sealed to the chamber by means of a flexible stainless-steel bellows. The non-chamber end of the mandrel is attached to a cross beam, which is guided by linear bearings on the vertical machine columns. The beam is loaded from underneath by a pneumatic bellows actuator assembly which includes an in-line force transducer for measurement of the load applied outside the chamber.

The force applied by the actuator is adjusted by means of a precision servo pneumatic valve. A second force transducer may be mounted inside the test chamber to measure the resulting in-chamber load force in order to calibrate the external load force transducer for different chamber operating pressures.

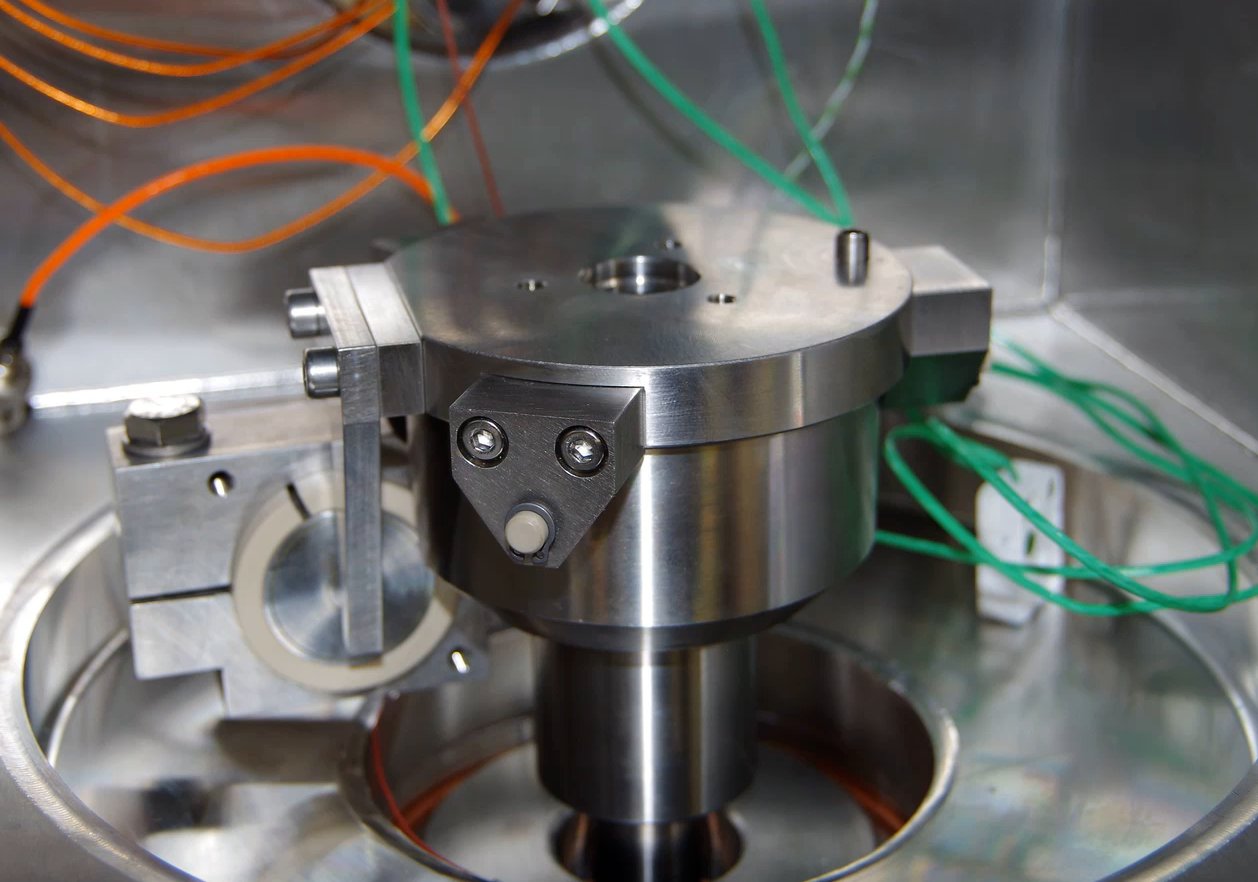

The friction torque measuring assembly incorporates a linear torsional flexure, the rotary displacement of which is sensed by means of a linear capacitance probe. The capacitance probe is subjected to an oscillating frequency and the response measured correlates with the change in capacitance as the gap between probe and target varies. As a charge as opposed to current device, the sensor is not subject to the unwanted sensor heating effects associated with equivalent strain gauge devices.

The fixed specimen tooling is electrically insulated from its surroundings and the rotating test spindle is fitted with an electrical slip ring allowing electrical contact potential measurements to be made across the specimen contact.

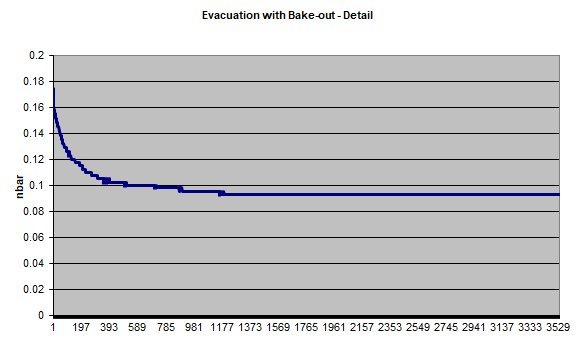

Bake-out heaters are provided within the test chamber to assist with out-gassing.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.Sliding Friction and Wear Tests

Sliding friction and wear tests are performed with test configurations equivalent to those specified in ASTM D2266 (sliding four ball), ASTM D3702 (thrust washer) and ASTM G99 (three in on disc).

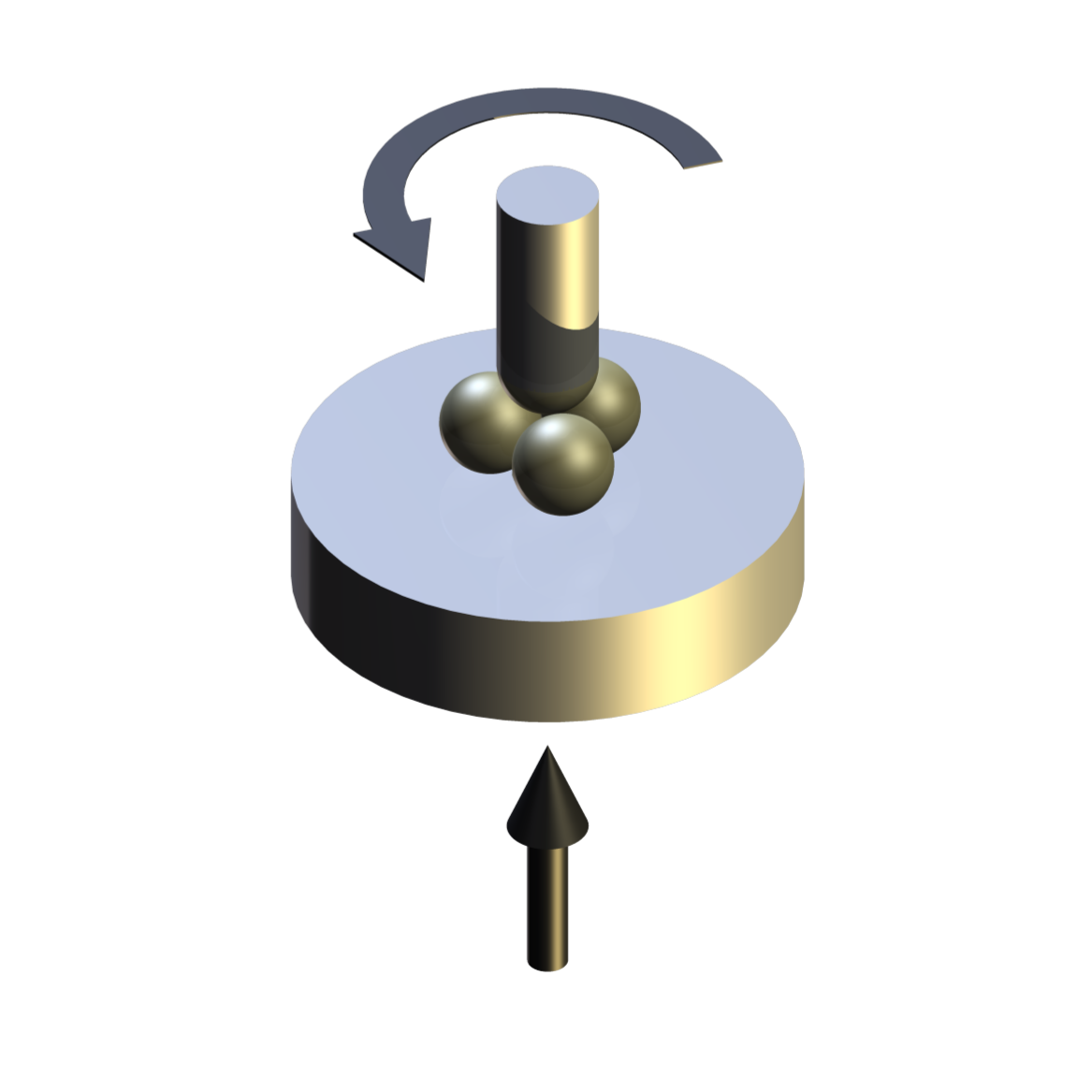

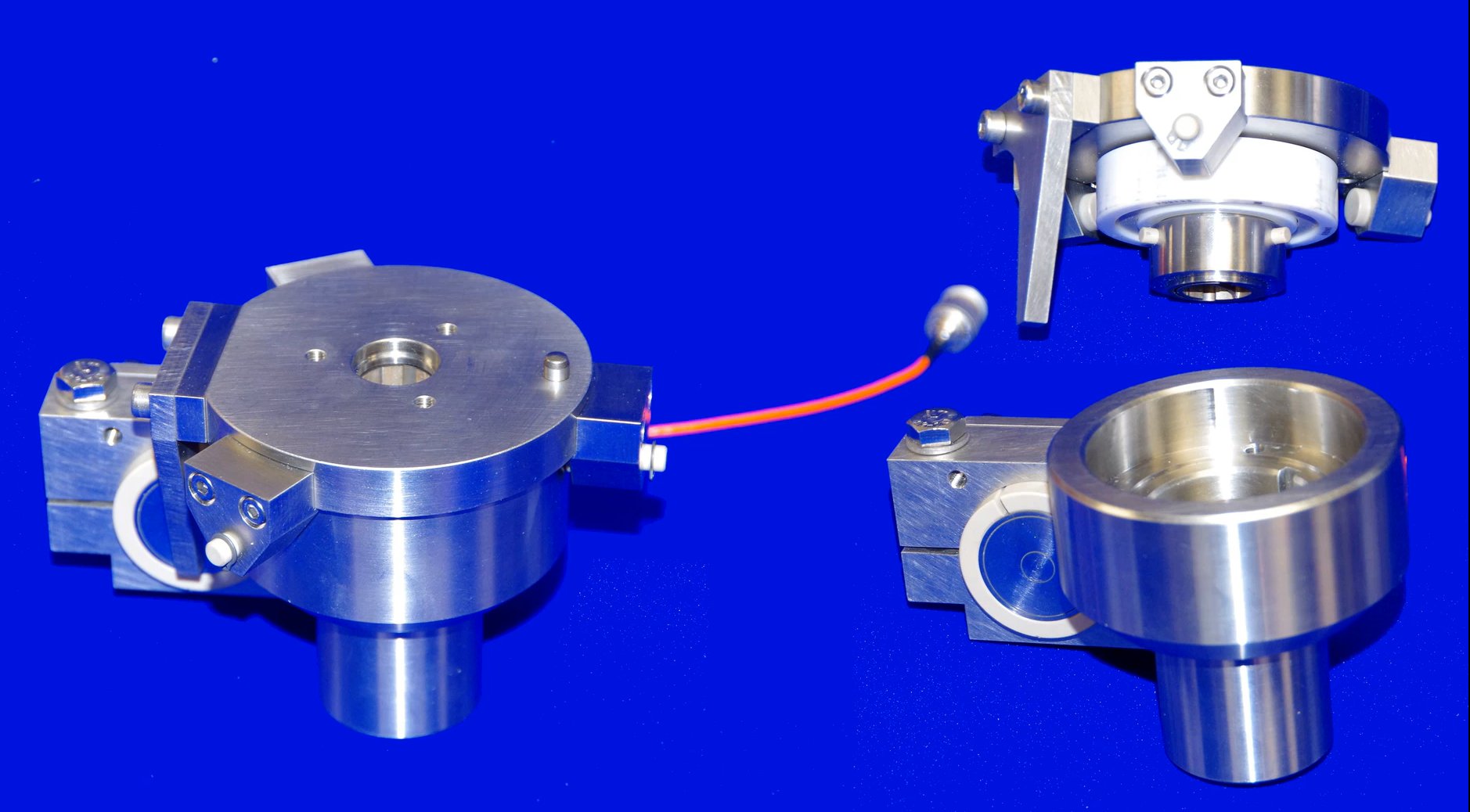

Four Ball Adapter

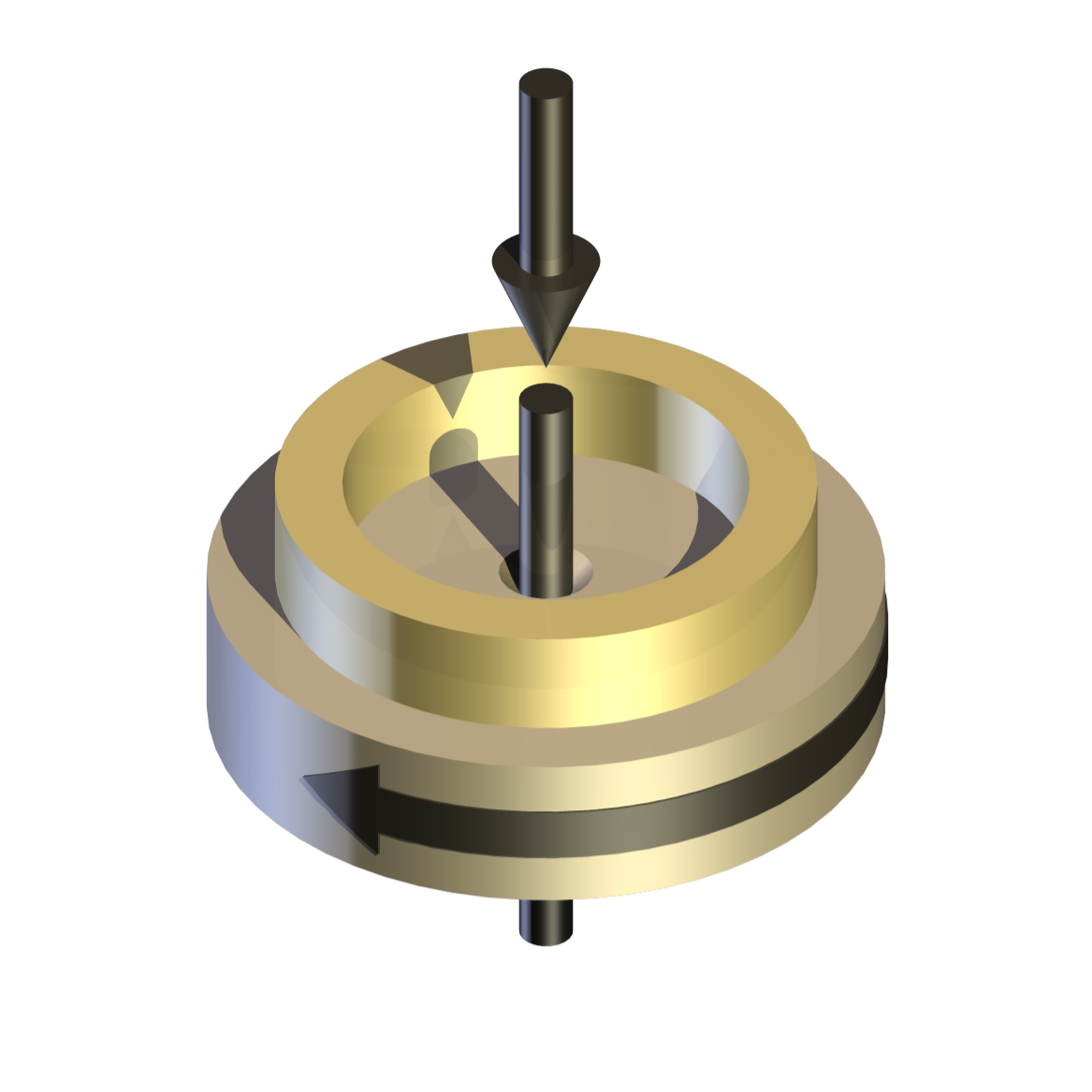

Thrust Washer/Pin on Disc Adapter Rolling Contact Fatigue Tests

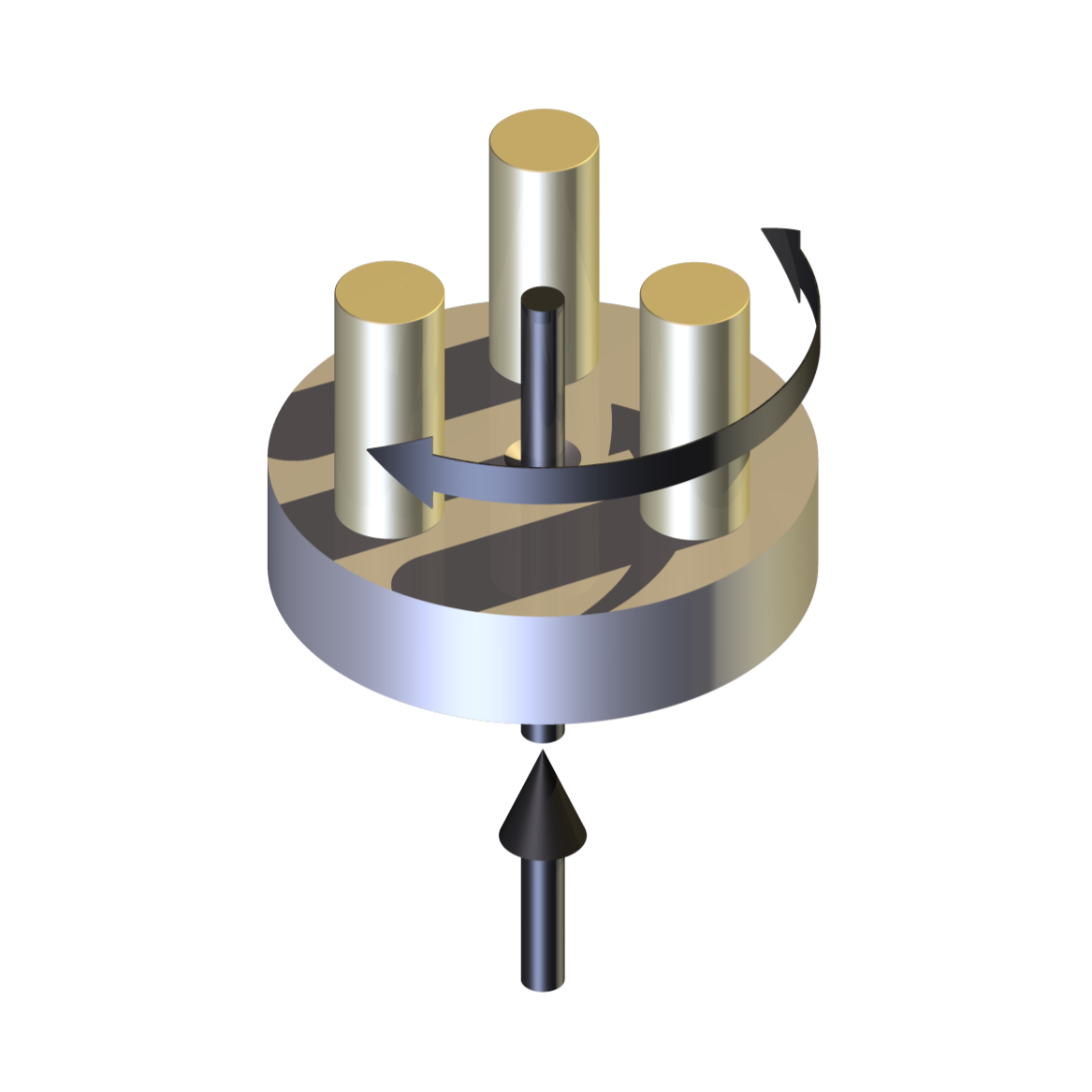

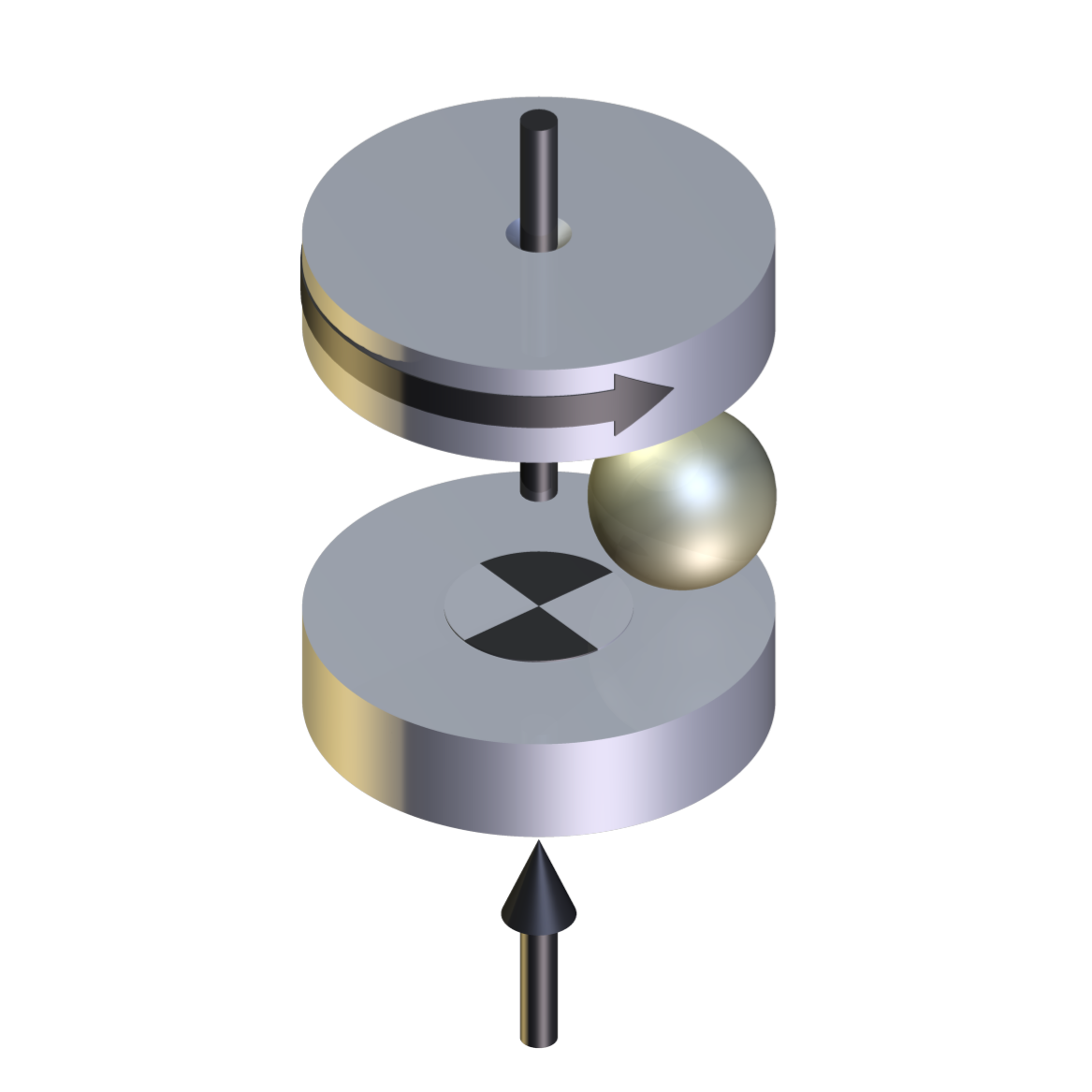

Rolling contact fatigue tests may be performed using the spiral orbit ball on disc test configuration. A lubricated ball is clamped between two parallel plates with one plate fixed and one plate rotating. The ball follows a spiral track and is maintained in orbit by contact once per revolution with an instrumented guide plate.

Spiral Orbit Adapter Instrumentation used with this adapter includes an orbit counter, piezo transducer and charge amplifier for scrub friction measurement and a high-speed data acquisition card for scrub force data capture.

-

Technical Specifications

Tribometer Load: 20 to 2000 N Rotational Speed: 10 to 1700 rpm Maximum Friction Torque: 5 Nm Load Actuation: Pneumatic Bellows Test Configurations: Four ball wear (ASTM D2266) Thrust washer (ASTM D3702) Three pin on disc (ASTM G99) Spiral orbit ball on disc (ASTM F2661) Motor Type: Servo with encoder feedback Roughing Pump: Rotary vane pump Vacuum Pump: Turbomolecular Interface: Serial Link Interface Module Software: COMPEND 2000 Test Chamber Vacuum: Down to 100 Picobar (10-5 Pa) Environment: Air, inert gas or vacuum Material: 304 stainless steel Surface Treatment: Glass bead blasted Viewports: Fused Silica Electrical Feedthrough: 1 kVolts , 15 Ampere Coaxial Feedthrough: BNC through Flange Thermocouple: Type K through Flange Vacuum Transducer: Cold Cathode and Pirani Leak rate: < 10-7 mbar l/s Rotary Feedthrough: Pressure up to 10-7 Pa Rotary Feedthrough: Temperature up to 80ºC Computer Controlled Parameters Rotational Speed Test Duration Load Manually Controlled Parameters Operating Pressure Recorded Parameters – Sliding Friction & Wear Load Rotational Speed Friction Torque Temperature Operating Pressure Electrical Contact Potential Number of Revolutions Test Duration Sliding Speed Sliding Distance Recorded Parameters – Rolling Contact Fatigue Load Rotational Speed Scrub Force Temperature Operating Pressure Electrical Contact Potential Number of Revolutions Number of Ball Orbits Test Duration Services Electricity: 220/240V, single phase, 50 Hz, 3 kW 110/120 V, single phase, 60 Hz, 3 kW -

Training Videos

-

Download the Machine Leaflet