-

Description

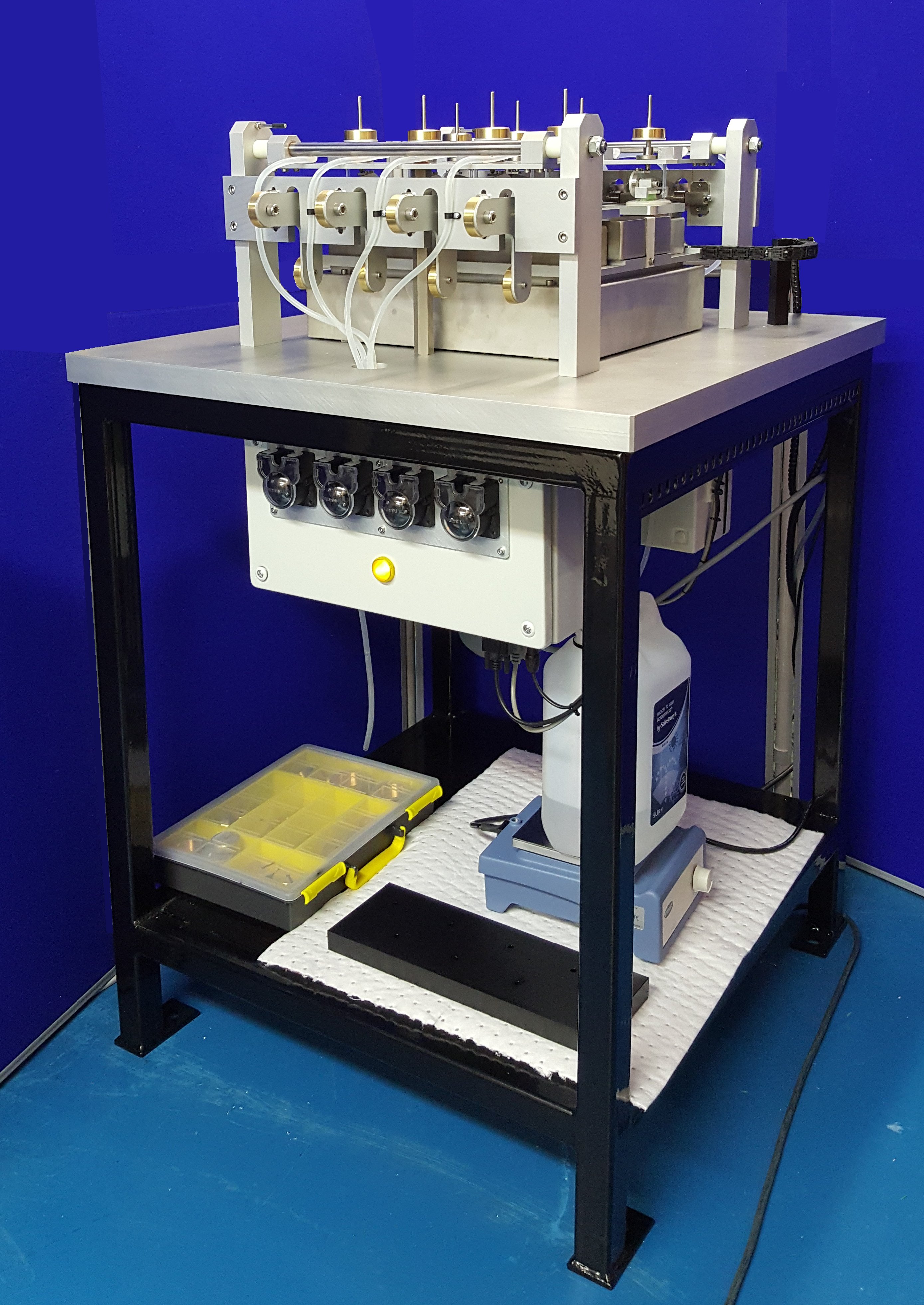

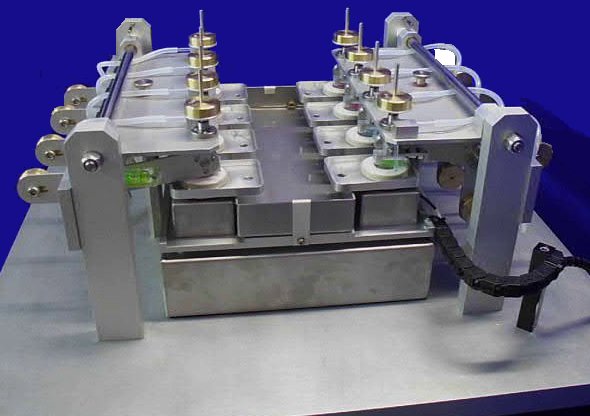

The TE 85 Eight Station Orbital Tooth Brushing Rig provides circular orbital, elliptical orbital and reciprocating motion, with fixed tooth brush samples loaded against moving teeth samples.

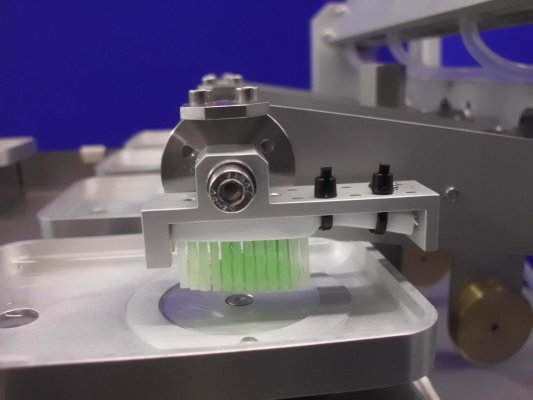

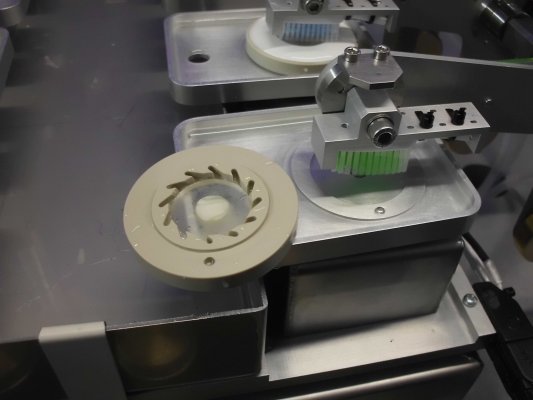

Toothbrushes are cut down for easy attachment to the loading arms.

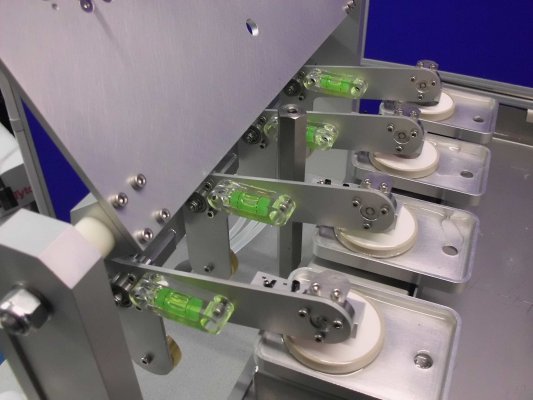

The arms are provided with adjustable counter weights allowing neutral balancing to be achieved.

Spirit levels are provided on each arm to aid with levelling.

Teeth samples, which are normally set in epoxy discs, are held in radially sprung fixtures.

These are then mounted in individual baths on the motion plate.

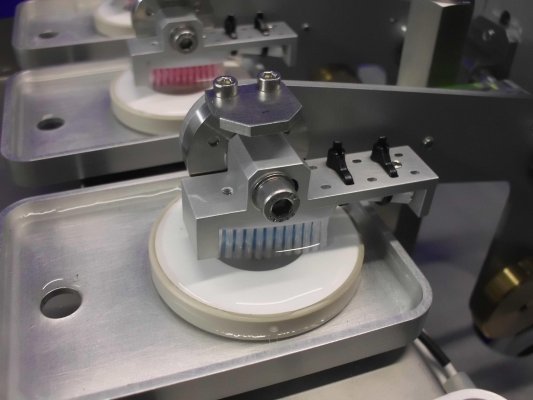

Load is applied directly to each toothbrush sample by dead-weights acting on linear bearing mounted load rods.

Motion System

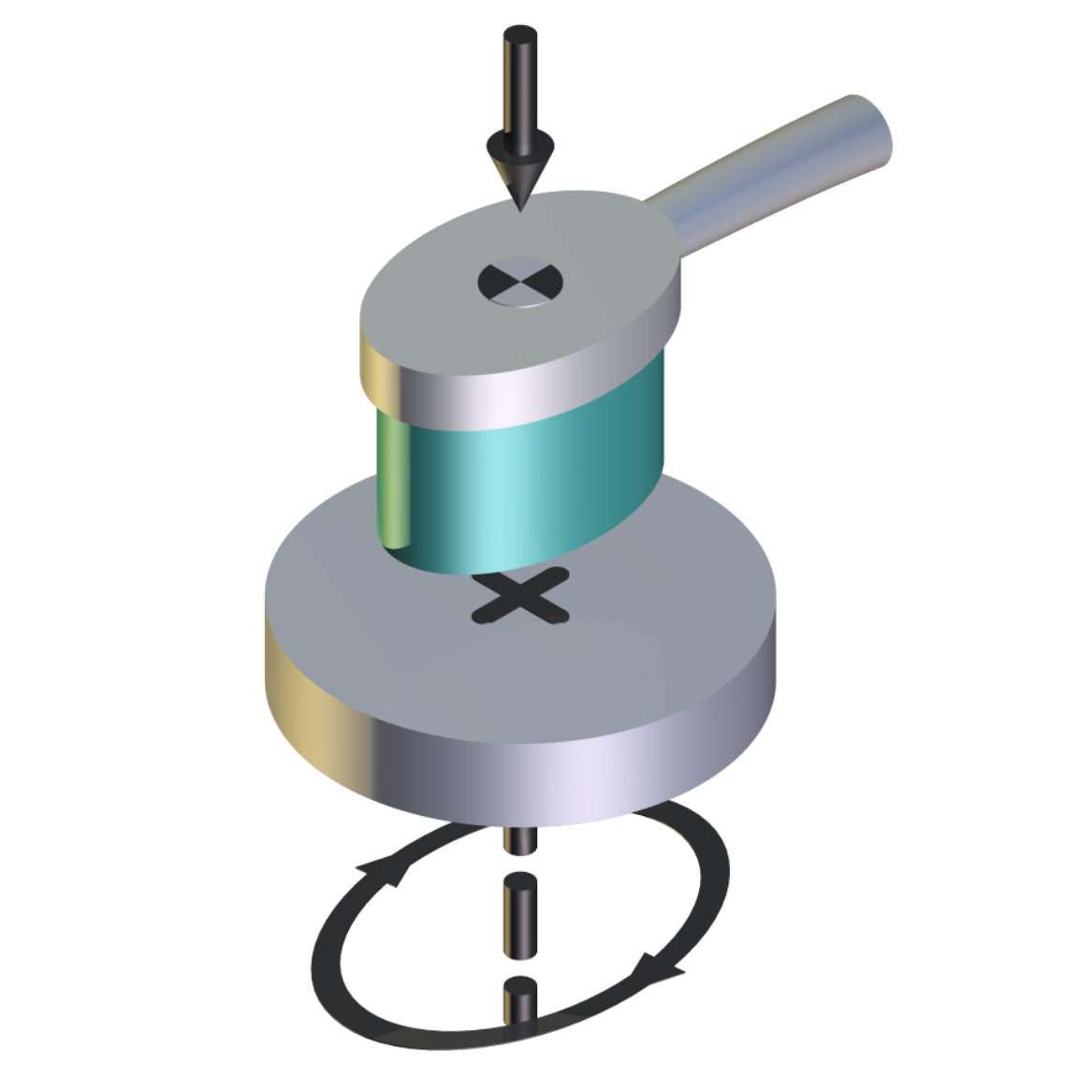

The motion system comprises a platform mounted on an x-y slide assembly and actuated by a double scotch yoke mechanism driven by an a.c. gear-motor. The frequency of motion is controlled by inverter and may be adjusted in the range 0.2 to 2.0 Hz. The displacement on one axis is set at an amplitude of 5 mm (stroke of 10 mm) and the amplitude on the orthogonal axis may be set at 0 mm (reciprocating), 1, 2, 3, 4 mm (elliptical orbital motion) or 5 mm (circular orbital motion).

Peristaltic Pumps

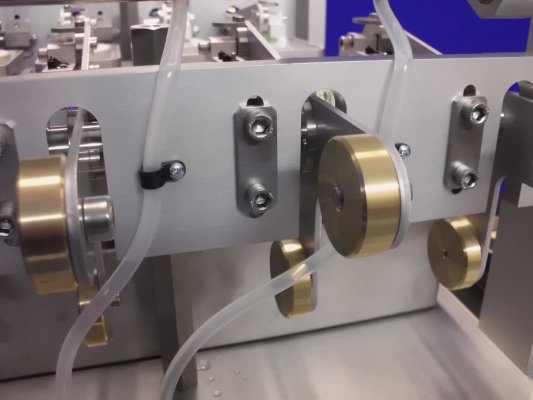

Eight computer controlled peristaltic pumps are included for delivery of fluid to each sample.

Three Axis Force Measurement

Optional three axis force transducers may be incorporated on as many stations as is required to provide measurement of applied load and frictional resistance on orthogonal axes. A high speed data acquisition interface is included for recording the signals.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Technical Specifications Load per brush: 150 to 500 grams Motion x direction: 10 mm (fixed) (+/-5 mm) Motion y direction: 0 to 10 mm in 2 mm steps (+/-0, 1, 2, 3, 4, 5 mm) Maximum Frequency: 2 Hz (120 rpm) Automatically Controlled Parameters Frequency Test Duration Fluid Flow Rate Manually Controlled Parameters Load Y Amplitude Measured Parameters Frequency Load (optional) Friction Force (optional) Number of Cycles Services Electricity: 220/240V, single phase, 50 Hz, 3 kW 110/120 V, single phase, 60 Hz, 3 kW -

Overview Videos

-

Index Tags

bio-medical products dental materials orbital motion tooth brushing toothbrush materials toothpaste toothpaste abrasivity -