-

Background

The DIN 51350-6 (KRL taper roller bearing) test method is concerned with the determination of the mechanical shear stability of lubricating oils with polymer additives, such as gear oils, engine oils, damper oils and automatic transmission fluids. For this a taper roller bearing is used to shear the fluid. The purpose of the test is to determine the permanent drop in viscosity caused by mechanical stresses under practical conditions. In many cases companies require to have a machine dedicated to such tests and this does not warrant the cost of a multi-functional machine.

The TE 82S is a manually controlled version of the standard TE 82. Tests may be run according to the following methods:DIN 51350/6 Testing of Shear Stability of Lubricating Oils Containing Polymers

CEC L-45-A-99 Viscosity Shear Stability of Transmission Lubricants (Taper Roller Bearing Rig)

ISO 26422:2014 Determination of shear stability of lubricating oils containing polymers – Method using a tapered roller bearing

Description

The machine frame comprises a base and top plate separated by two rigid vertical columns. This arrangement ensures accurate location of the test spindle housing with respect to the normal loading axis. The machine is bench-mounting and is supplied with a transparent safety cover and safety interlocks.

The test spindle projects downwards from the top plate and runs in a housing with precision greased for life bearings. The drive motor is also mounted on the top plate and is connected to a pulley on the test spindle by means of a timing belt.

The shear test assembly is mounted on a massive aluminium cross beam which is guided by linear bearings on the vertical machine columns. The beam is loaded from underneath by means of a loading arm with 20:1 lever ratio. This means that only 50 kg is required to achieve the highest machine load.

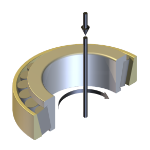

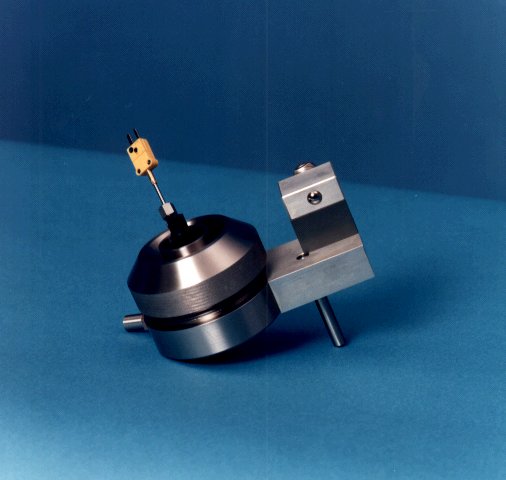

The test assembly comprises a threaded test reservoir, clamping nut, integral labyrinth for temperature control, torque arm and thermocouple sensor. The taper roller bearing is a standard commercial production bearing. The outer race locates into the test reservoir and the bearing is re-assembled. The clamping nut is screwed down by hand to hold the outer race.

A central hole in the clamping nut permits the inner race to be rotated by a driver that locates in the spindle taper. Although there is no torque measurement, the torque arm is used to prevent the test assembly rotating during the test.

A thermocouple is located in the clamping nut with the tip of the sensor protruding into the space just above the inner race which is normally flooded with lubricant. The temperature of the lubricant must be maintained at 60°C for the test. To achieve this control, the base of the test assembly is machined with a labyrinth of water passages and a temperature controlled recirculating water system is provided.

The recirculating system has a sump tank with integral electrical heater element, thermocouple, set point temperature controller and circulating pump. When cooling is required a thermostatic switch opens an inlet valve to the sump tank to take in mains water.

Instrumentation

Variable speed drive with encoder feedback and digital speed display

Pre-set batch counter controlling the number of cycles completed (this is more precise than setting a speed and measuring time)

PID setpoint temperature controller with display for the recirculating system

K-type thermocouples for monitoring temperature in the test assembly and sump tank

-

Technical Specifications

Technical Specifications Load Range: 500 to 10,000 N Rotational Speed: 60 to 1,780 rpm Taper Bearing: SKF 32008 X/Q Temperature Sensor: k-type thermocouple Sump Capacity: 35 litres Heater Power: 3 kW Pump Flow: 9 litres/minute at zero head Temperature: 60°C Motor: 2.2 kW ac Automatically Controlled Parameters Temperatures Test Duration Manually Controlled Parameters Load Rotational Speed Services Electricity: 220/240V, single phase, 50/60 Hz, 7.5 kW Mains water and drain Installation Floor-standing machine: 900 x 670 deep x 2000 mm high, 300 kg Packing Specifications: 2.2 m3, GW 600 kg, NW 450 kg -

Applications

shear stability test taper roller bearing VI improvers -

User List

New simplified version of TE 92S machine – Launched 2011

Idemitsu Japan -

Download the Machine Leaflet