-

Background

The TE 73 family of machines dates back to original Plint and Partners Ltd designs from the 1960s. These machines are all to the “overhung” roller design in which test rollers are mounted on the end of spindles and in which the spindle housings are mounted adjacent to each other. This arrangement has the obvious benefit of making the rollers much more accessible than in other configurations. There is, however, one significant consequence of this arrangement and that is that, with equal sized rollers, the roller diameter must obviously be greater than the spindle housing diameter. In other words, the diameters of the spindle housings fix the minimum shaft centre distance and thus determine the minimum diameter of roller that can be accommodated. This configuration is thus only suitable for experiments using quite large diameter rollers, the consequences of which are:

- The larger the diameter, the greater the torque generated, for a given load and traction coefficient.

- The larger the diameter, the more expensive the rollers become to manufacture.

Despite these caveats, it is of course worth noting that there are known scale effects with two roller or twin disc tests, so in some circumstances, adequate correlation can only sensibly be achieved when performing tests with rollers of sufficient size. For obvious reasons, tests demanding high surface speeds are best achieved with larger diameter rollers, likewise tests requiring a long hertzian contact length. Finally, if large amounts of frictional heat are to be dissipated in the contact, the larger the roller, the larger the thermal mass and surface area and the better the heat dissipation. Small rollers can become unrepresentatively hot!

The early TE 73 machines were primarily used for the study of highly loaded lubricated power transmitting contacts and rolling contact fatigue of materials. The successful operation of machine elements such as gears, rolling bearings, cam/follower systems and traction drives is vital to industry. The common feature to all these is that fact that power or motion is transmitted through highly loaded lubricated contacts with rolling or combined rolling and sliding motion.

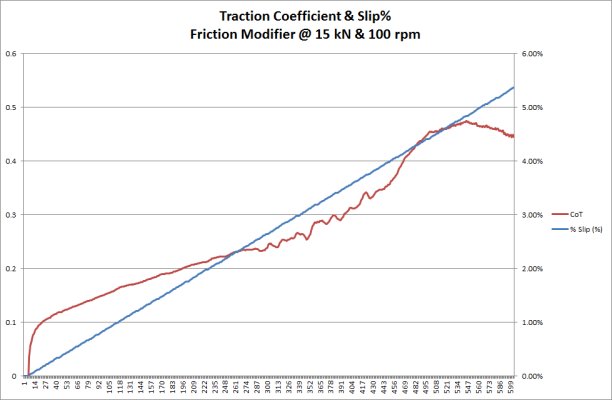

In the TE 73, the two rollers are driven at different speeds to give varying amounts of slip in the contact and therefore to transmit increasing amounts of traction. The maximum traction coefficient is obtained at a particular value of slip and this is a characteristic of an individual fluid.

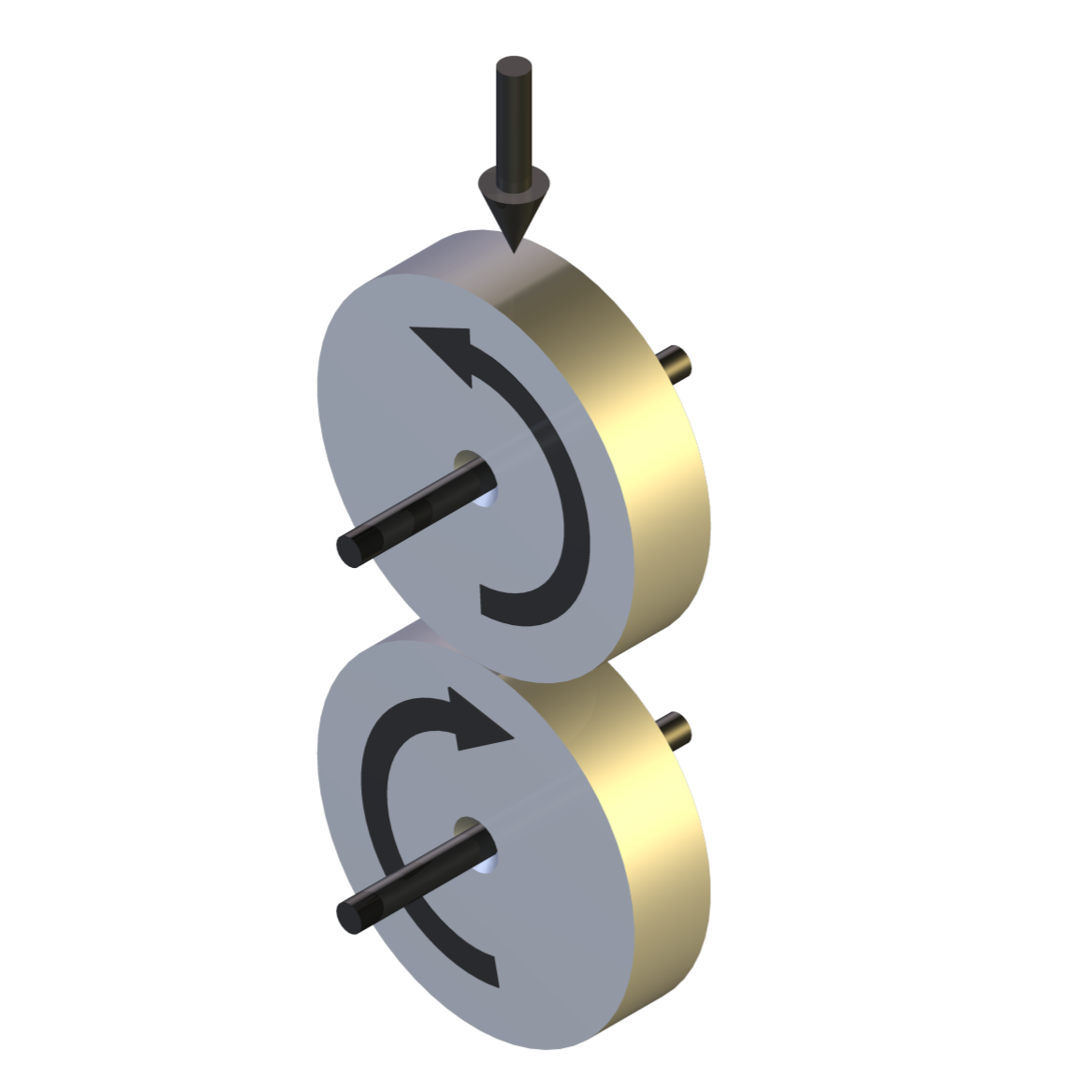

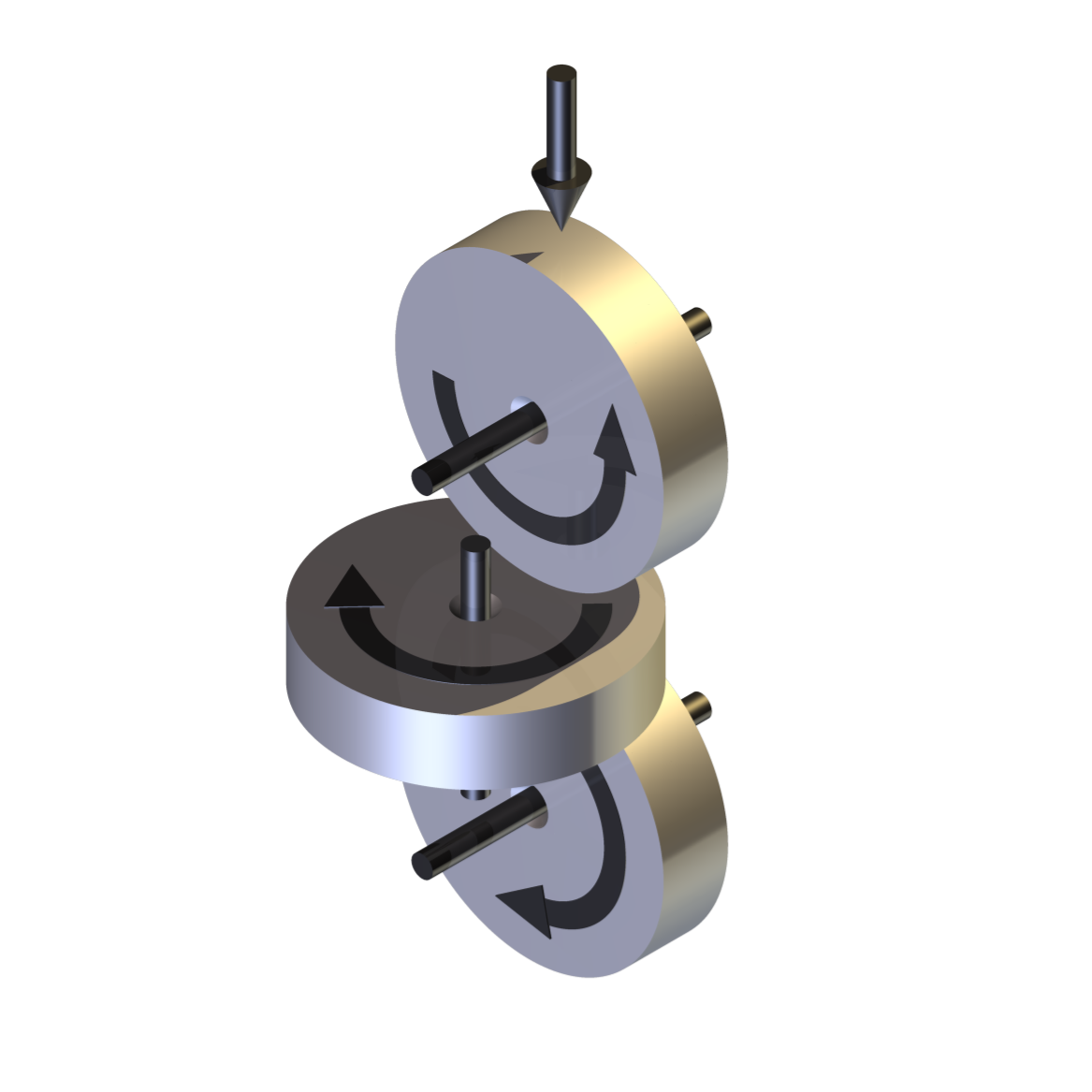

In modern variable ratio gear systems there is an additional complication. It is an inherent property of this kind of mechanism that there is a velocity gradient across the width of the contact zone in a direction perpendicular to the rolling direction. In other words there is spin in the contact zone. The effect of spin is to modify the traction slip characteristic. The distinction between the high and low slip regions is lost and instead there is a more gradual growth in traction as slip increases. This phenomenon can be studied in the TE 73 by introducing a third disc between the two rollers, that is free to rotate about a perpendicular axis.

Legacy DesignLegacy Design

TE 73 – Original Design

TE 73 – Original DesignIn the original design, two roller specimens are mounted one above the other on the ends of parallel test shafts, which are connected to a helical gear pair at the rear of the machine. This is thus a “four-square” or “back-to-back” design. The lower shaft is driven by a variable speed motor, through a belt drive. The motor supplies only the losses in the loop, not the full tractive power which is locked into the torque loop.

Slip percentages from 0% (pure rolling) to 8% are selected by installing an appropriate gear pair. The test rollers have a crowned profile giving a well-defined circular contact zone and high Hertzian contact pressures.

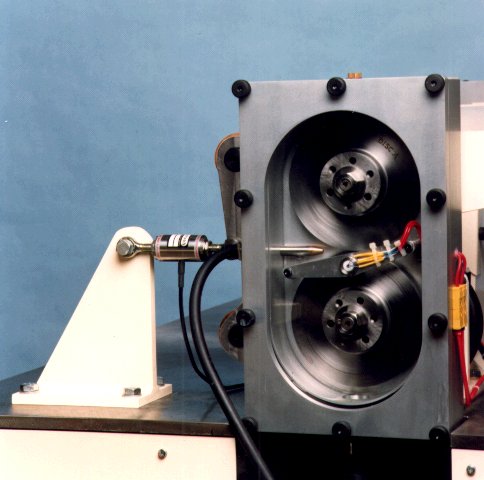

The lower shaft housing is fixed while the upper housing is hinged to allow motion in the transverse and vertical directions. A static compressive load is applied manually via a lever to the roller contact and this value is measured by an in-line strain gauge load cell. A separate load cell mounted in the transverse direction measures the traction forces in the contact.Current Design

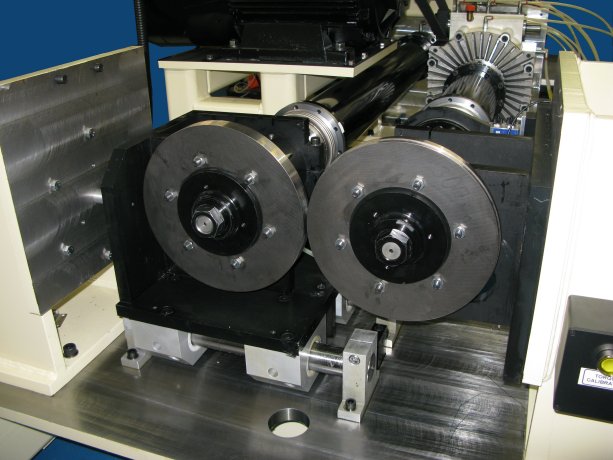

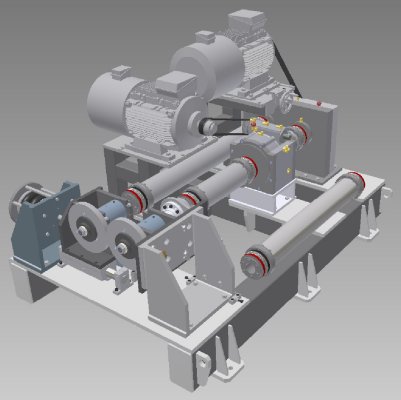

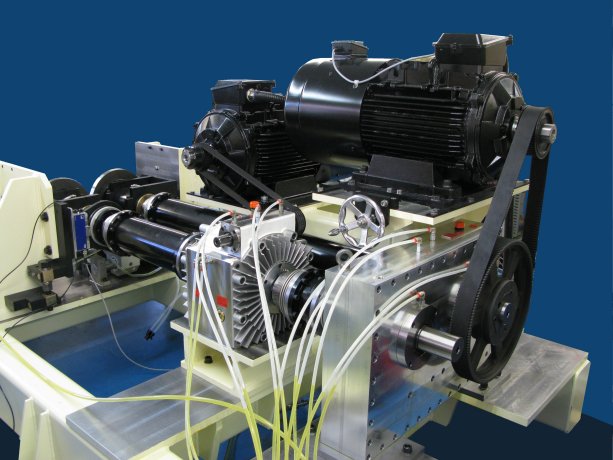

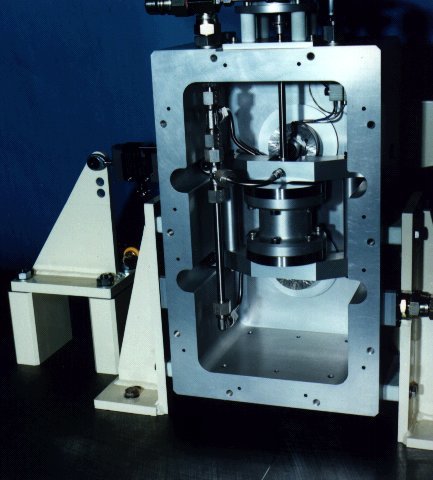

In the current TE 73 designs, the test rollers are mounted on a horizontal axis, side-by-side, with one spindle housing mounted on a linear slide, allowing it to be indexed towards, and hence loaded against, a fixed spindle. The advantage of mounting the rollers side-by-side is that it removes the requirement to adjust for the tare weight of the upper roller spindle, as in the vertically arranged design. Torque is measured with an in-line torque transducer as opposed to torque reaction mounting of one of the spindle housings.

Roller spindles are oil lubricated from a lubricant service unit. Seal friction is eliminated by the use of non-contacting labyrinth seals. One roller assembly is pivoted with a mechanism to achieve up to 1% skew adjustment.

Two different drive systems are available, depending on the size of roller to be tested and hence the required system power and torque. The modern, twin motor solution, with electrical power circulation, has the advantage over the back-to-back gear arrangement in allowing continuous variation of slide-roll ratio, while the machine is running. However, it will be apparent that as roller diameters increase, larger capacity motors are required and at some point, it becomes necessary to revert to a back-to-back gear design. The challenge here is to provide continuous variation of side-roll ratio with a fixed gear design.

The current designs may be used for both dry and lubricated tests.TE 73S Two Roller Machine – Circulating Power

The TE 73S is a twin motor unit incorporating two 30 kW a.c. vector motors with vector drives power from a common d.c. bus. One motor is driving, drawing power from the bus and the other motor is acting as a generator, loading the system and dumping power onto the bus. This arrangement allows continuous variation of speed and slide-roll ratio. The minimum roller diameter is 145 mm and the maximum diameter is 155 mm.

TE 73H Two Roller Machine – Circulating Torque

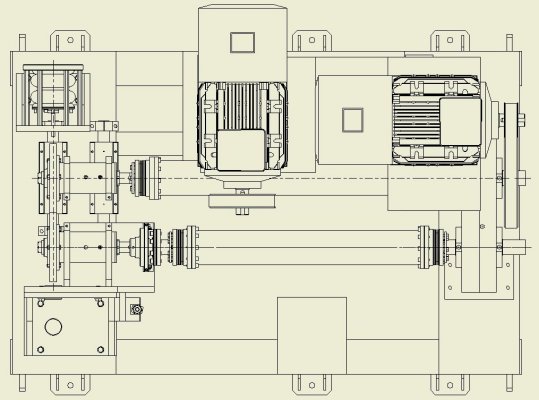

The TE 73H is a back-to-back gear unit designed to operate with large diameter discs, thus generating high torques and transmitting high levels of power through the roller contact. The minimum roller diameter is 280 mm and the maximum diameter is 320 mm. Two drive arrangements are provided, one for low rotational speeds involving continuously variable slide-roll ratio and one for high speeds with fixed slide-roll ratio.

TE 73H – Variable Slide-Roll Range

TE 73H – Variable Slide-Roll RangeAt low speeds, up to a maximum of 500 rpm, a speed modulating, two-stage, epicyclic gear-box is included in the torque loop. By driving the ring gear on the output stage of the gear-box, the output speed can be adjusted by +/-22 rpm, hence, for an input speed of, say, 100 rpm, the output speed can be adjusted to 100 +/-22 rpm and 500 rpm to 500 +/-22 rpm. The torque loop is completed with a two axle, close ratio, gear-box.

The torque loop system losses are provided by a 30 kW vector motor rotating the loop through an input shaft on the close ratio gear-box. A second 30 kW motor drives the ring gear on the epicyclic gear-box, thus allowing speed modulation.

It should be noted that although the two motors are powered by twin vector drives, each drawing power from a common d.c. bus, thus potentially allowing electrical power recirculation, in this case both motors are actually driving, not one motor driving and the other acting as a generator.

TE 73H – Fixed Slide-Roll Range

TE 73H – Fixed Slide-Roll RangeThe speed limit of 500 rpm is determined by the operating limits of the speed modulating gear-box. Above this speed, the speed modulating gear-box is taken out of the torque loop and its associated motor disabled. At speeds up to 1780 rpm (a surface speed of 100 kph with 300 mm rollers) the machine operates with a fixed slide-roll ratio, set by the gear pair in the parallel shaft gear-box. Gear-boxes with ratios from 100:100 to 100:90 are available. It must of course be remembered that these gear-boxes are used at the lower speed range in conjunction with the speed modulating gear-box, an ideal combination being the latter with a 100:99 parallel shaft box.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.TE 73/S Contact Spin Adapter

One major application of rolling contact power transmission is in continuously variable transmissions. In such devices, of whatever configuration, the geometry of contact is such that there is a degree of rotation of one surface relative to the other and not pure rolling/sliding. This relative rotation or spin has a profound effect on the performance of the transmission:

- substantial losses occur, even when no power is being transmitted

- flash temperature effects become significant

- the degree of slip for maximum traction is greatly increased

- the overall efficiency is strongly dependent on the degree of spin

In the TE 73, relative motion of the two rollers is limited to combinations of pure rolling with varying rates of sliding in the rolling direction. Spin is introduced into the contact by running the machine with a third disc, whose axis is vertical, between the two smaller diameter test rollers. Two contacts are formed, one on the upper surface of the third disc and one on the lower surface and the contact shape is elliptical.

The degree of spin in the contacts may be varied over a range encountered in transmissions by changing the radius at which the two rollers contact the third disc. The TE 73/S is interchangeable with the standard two-roller configuration.

-

Technical Specifications

Technical Specifications – TE 73S

Type: Circulating power Overhung roller Spindles parallel Limited variable shaft centre distance Contact: Line or point contact Test Conditions: Pure Rolling Sliding/Rolling Environment: Dry & Lubricated Standard Roller Diameter: 150 mm on 150 mm Maximum Shaft Centre Distance: 155 mm Minimum Shaft Centre Distance: 145 mm Maximum Roller Thickness: 30 mm Maximum Load: 21 kN Continuously Variable Slide-Roll: 0 to 3000 rpm Slide-Roll Ratio: 0 – 200 % (pure rolling to pure sliding) Roller Temperature: Ambient to 150°C Maximum Motor Power: 30 kW @ 1500 rpm Motor Base Speed: 1500 rpm Maximum Motor Speed: 3000 rpm Maximum Spindle Speed: 6000 rpm Drive Ratio: 1:1 Maximum Torque at 1500 rpm: 190 Nm Maximum Torque at 3000 rpm: 95 Nm Maximum Surface Speed (150 mm Roller): 11 ms-1 Drive Ratio: 2:1 Maximum Torque at 1500 rpm: 95 Nm Maximum Torque at 3000 rpm: 47.5 Nm Maximum Surface Speed (150 mm Roller): 22 ms-1 Spin Adapter: Optional Controlled Parameters Motor speed Motor speed difference Applied load Test fluid temperature Test duration Measured Parameters Motor speed Motor speed difference Applied load Transmitted torque Lubricant inlet temperature Test bath outlet temperature Vibration sensor output Electrical contact resistance Services Electricity: 380/415V, three phase plus neutral, 50/60 Hz, 75 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Mains water and drain: 10 l/min (typical) Technical Specifications – TE 73H

Type: Circulating torque Overhung roller Spindles parallel Limited variable shaft centre distance Contact: Line or point contact Test Conditions: Pure Rolling Sliding/Rolling Environment: Dry & Lubricated Standard Roller Diameter: 300 mm on 300 mm Maximum Roller Thickness: 30 mm Maximum Shaft Centre Distance: 320 mm Minimum Shaft Centre Distance: 280 mm Maximum Load: 21 kN Continuously Variable Slide-Roll: 0 to 500 rpm Speed Modulation: +/-22 rpm Fixed Slide-Roll: 0 to 1800 rpm Roller Temperature: Ambient to 150°C Maximum Motor Power: 30 kW @ 1500 rpm Maximum Motor Speed: 3000 rpm Maximum Spindle Speed: 1800 rpm Maximum Roller Torque: 1200 Nm Maximum Transmitted Power: 225 kW @ 1800 rpm Speed Modulation Gear-box: Rated at 1200 Nm at 0 to 500 rpm Plate Gear-box /Gear-boxes: Rated to 225 kW at 1800 rpm on 300 mm centres Available Gear-box Ratios: 100:100 to 100:90 Spin Adapter: Optional Controlled Parameters Motor speed Motor speed difference Applied load Test fluid temperature Test duration Measured Parameters Motor speed Motor speed difference Applied load Transmitted torque Lubricant inlet temperature Test bath outlet temperature Vibration sensor output Electrical contact resistance Services Electricity: 380/415V, three phase plus neutral, 50/60 Hz, 75 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Mains water and drain: 10 l/min (typical) -

High Speed Operations

-

Download the Machine Leaflet