-

Description

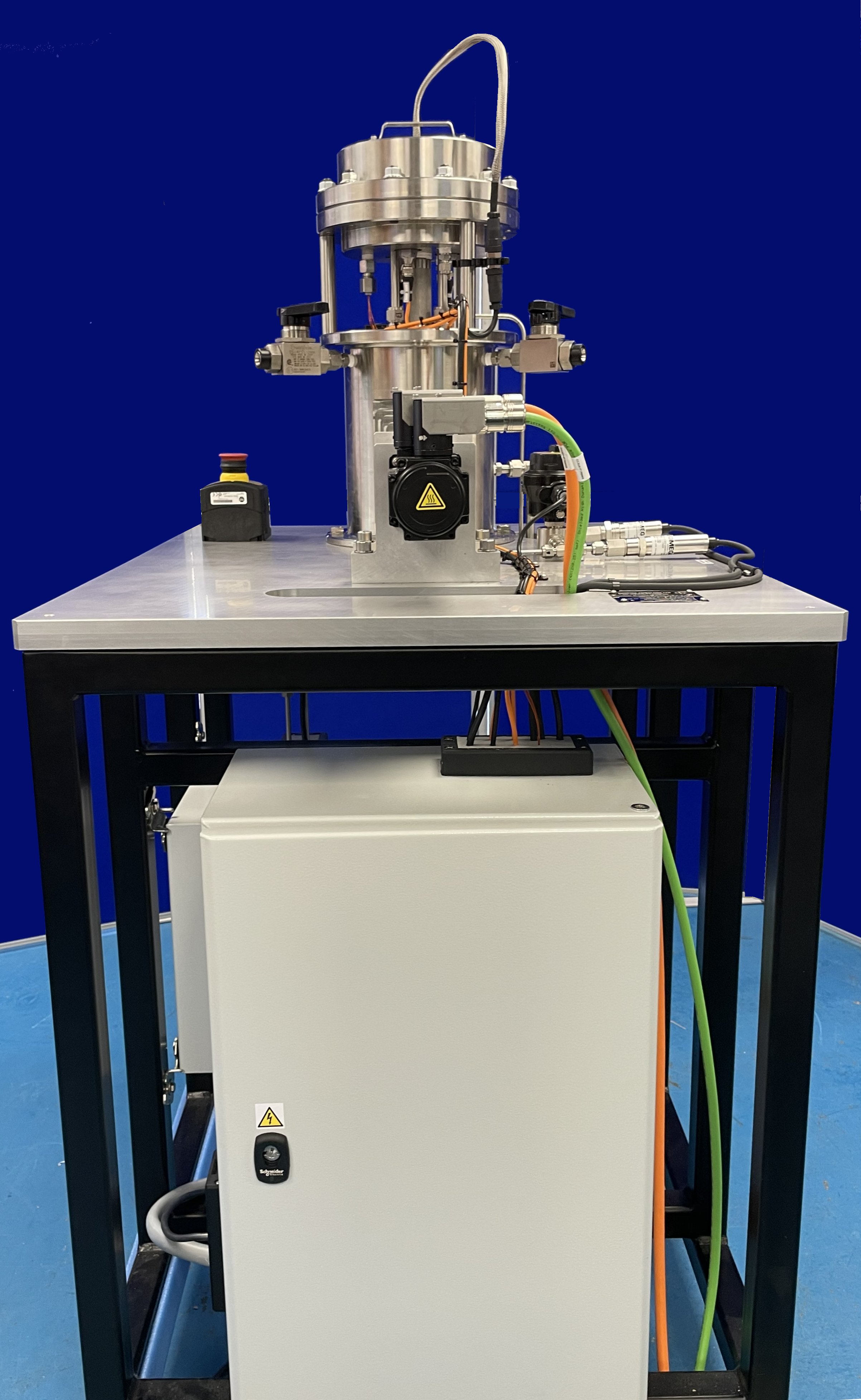

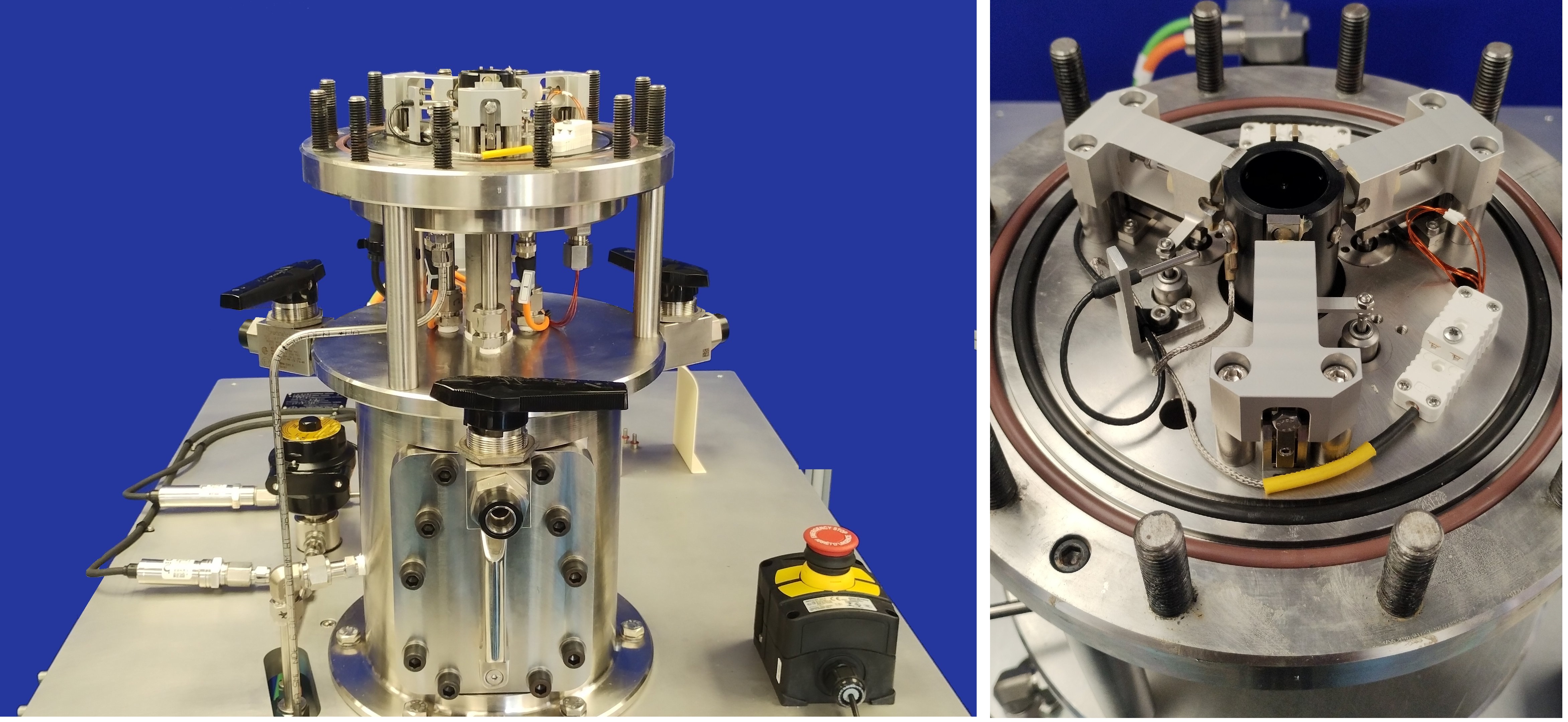

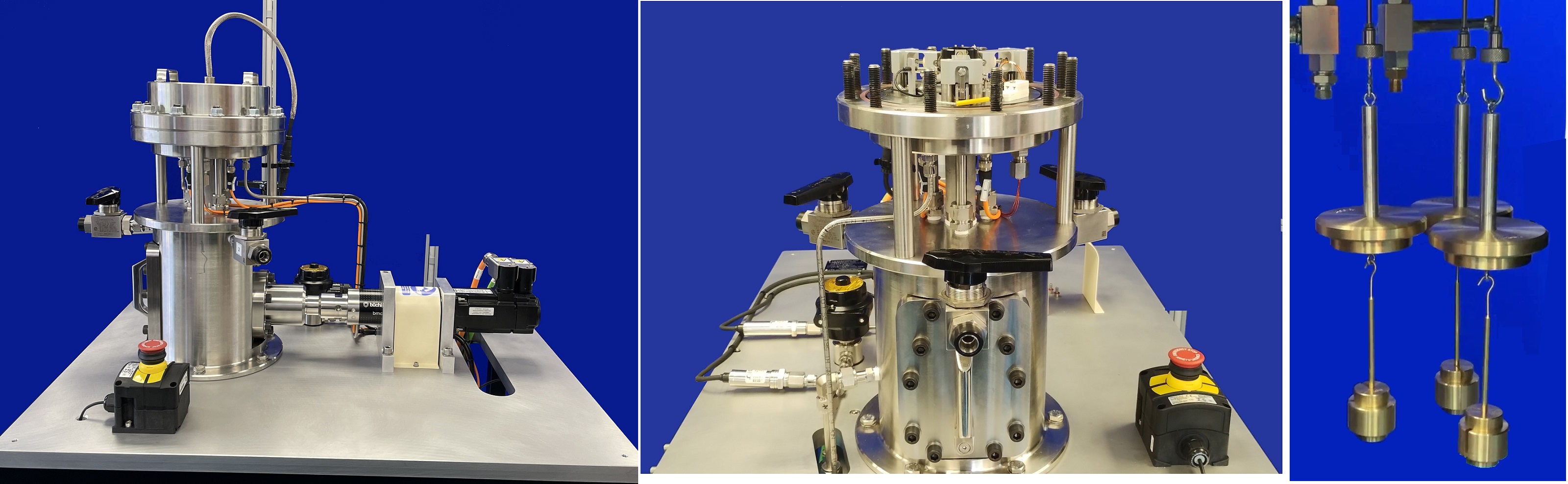

TE 60 is a three-station reciprocating tribometer, designed around a high pressure chamber, for experiments under hydrogen and other gases. It includes a vacuum pump for purging the chamber before charging with a chosen gas, so can also be used for tests under medium vacuum. Tests may be run with plate specimen temperatures from -50°C to +150°C.

High PressureChamber

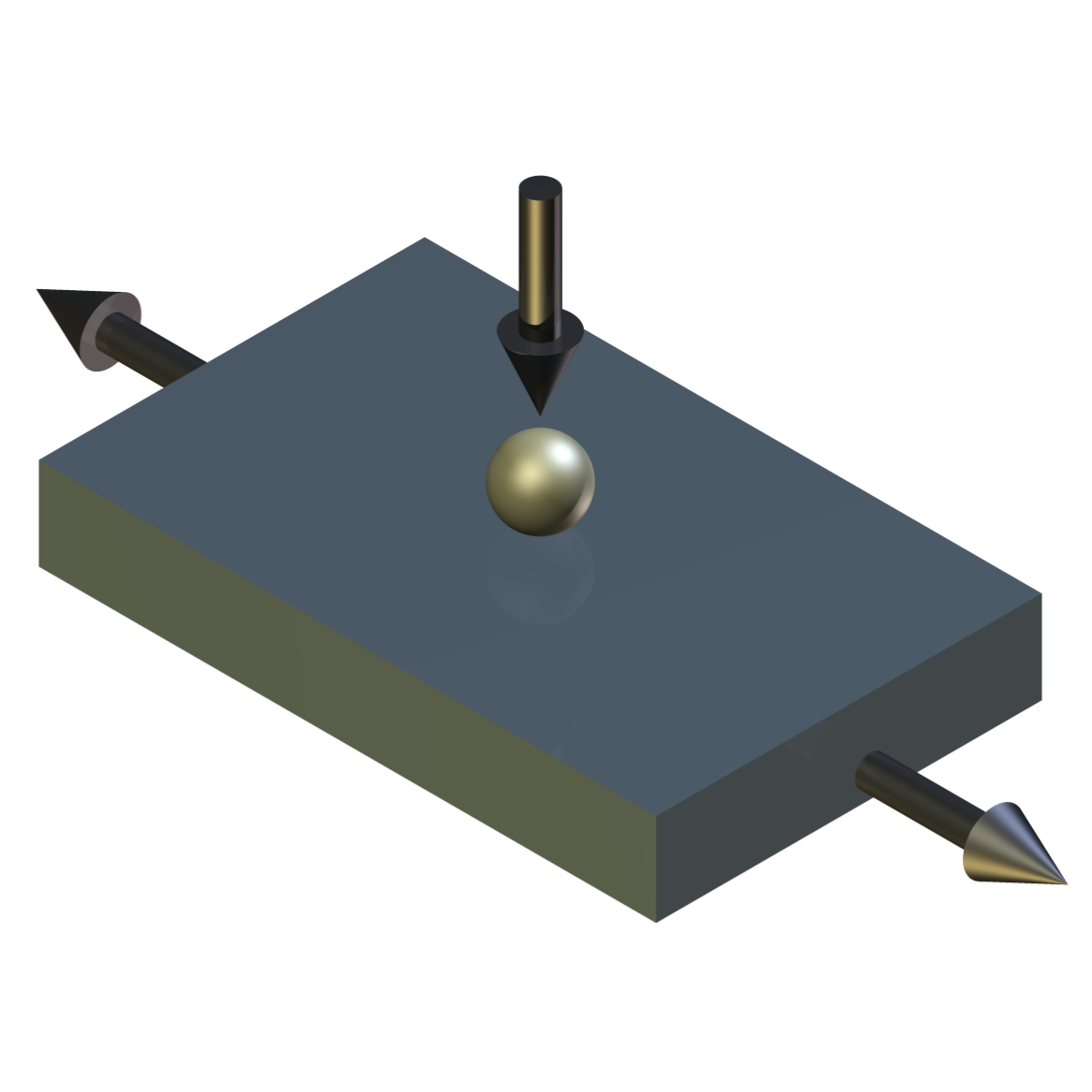

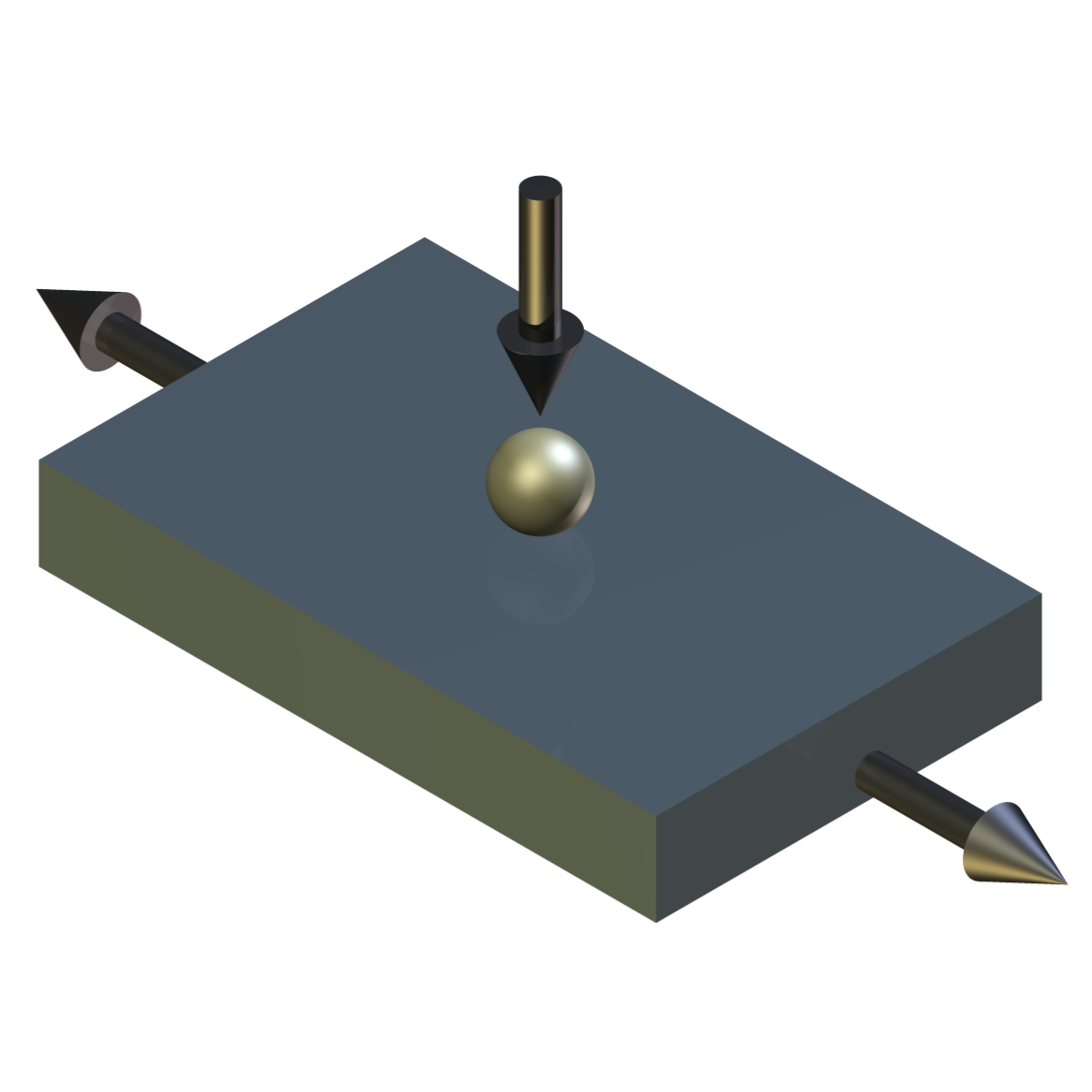

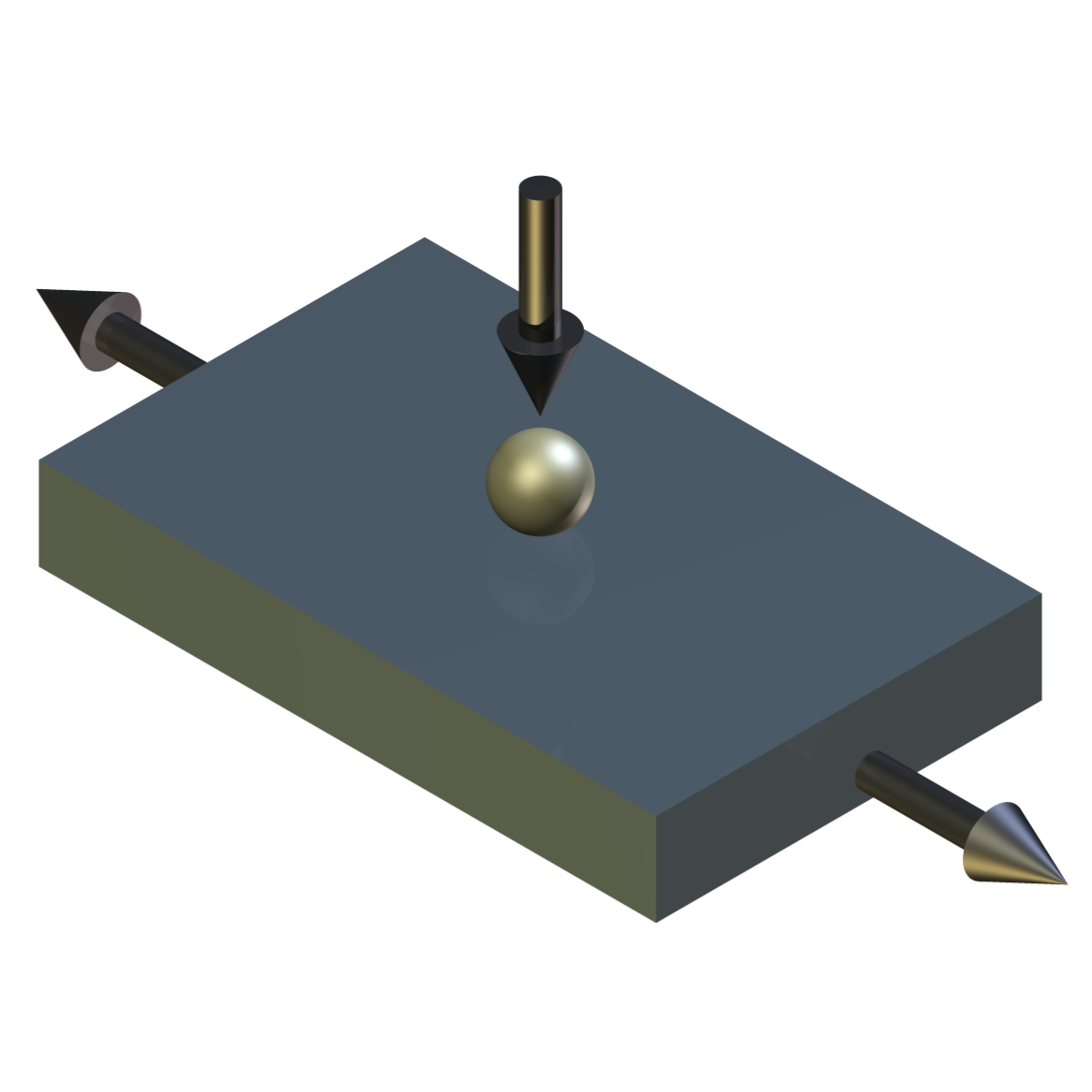

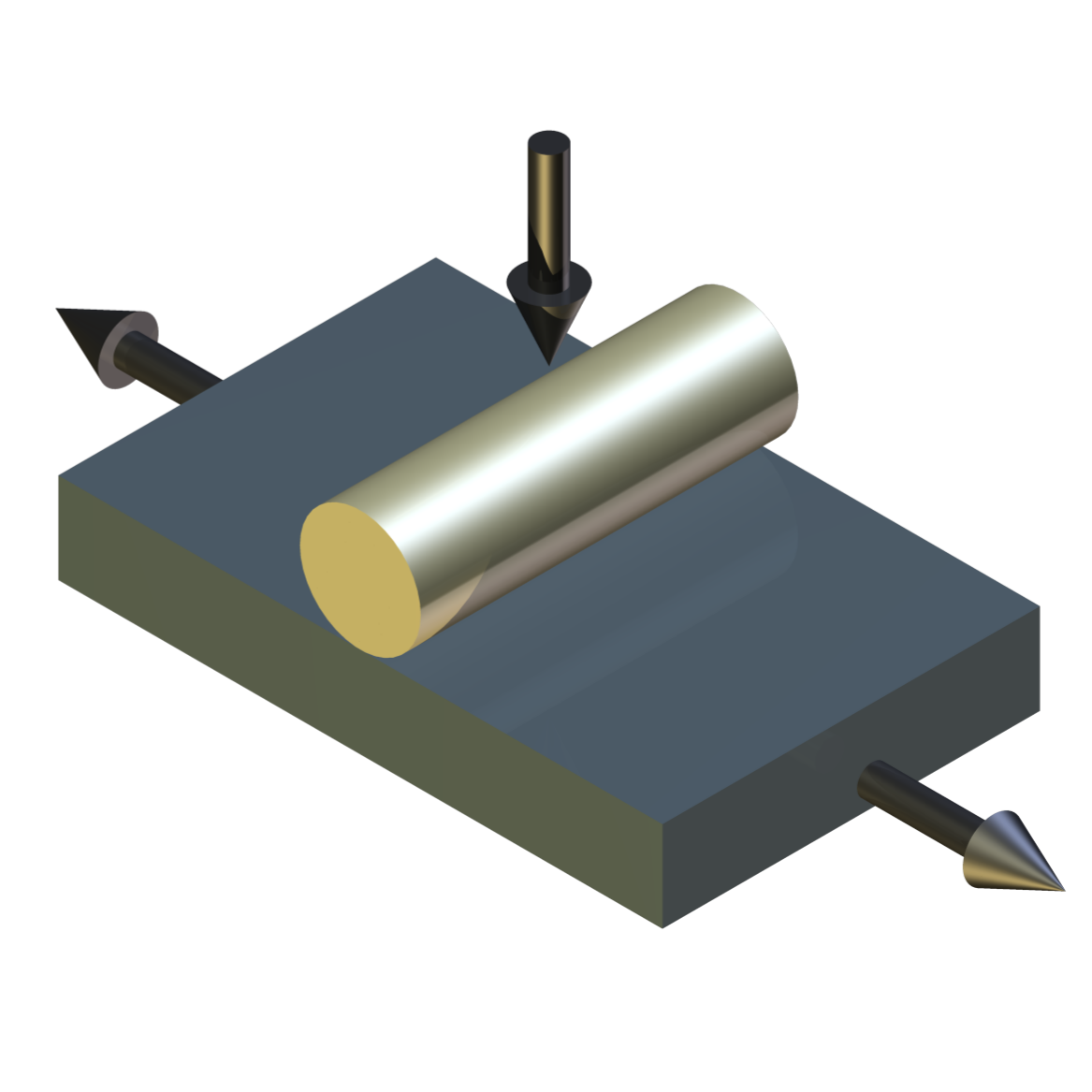

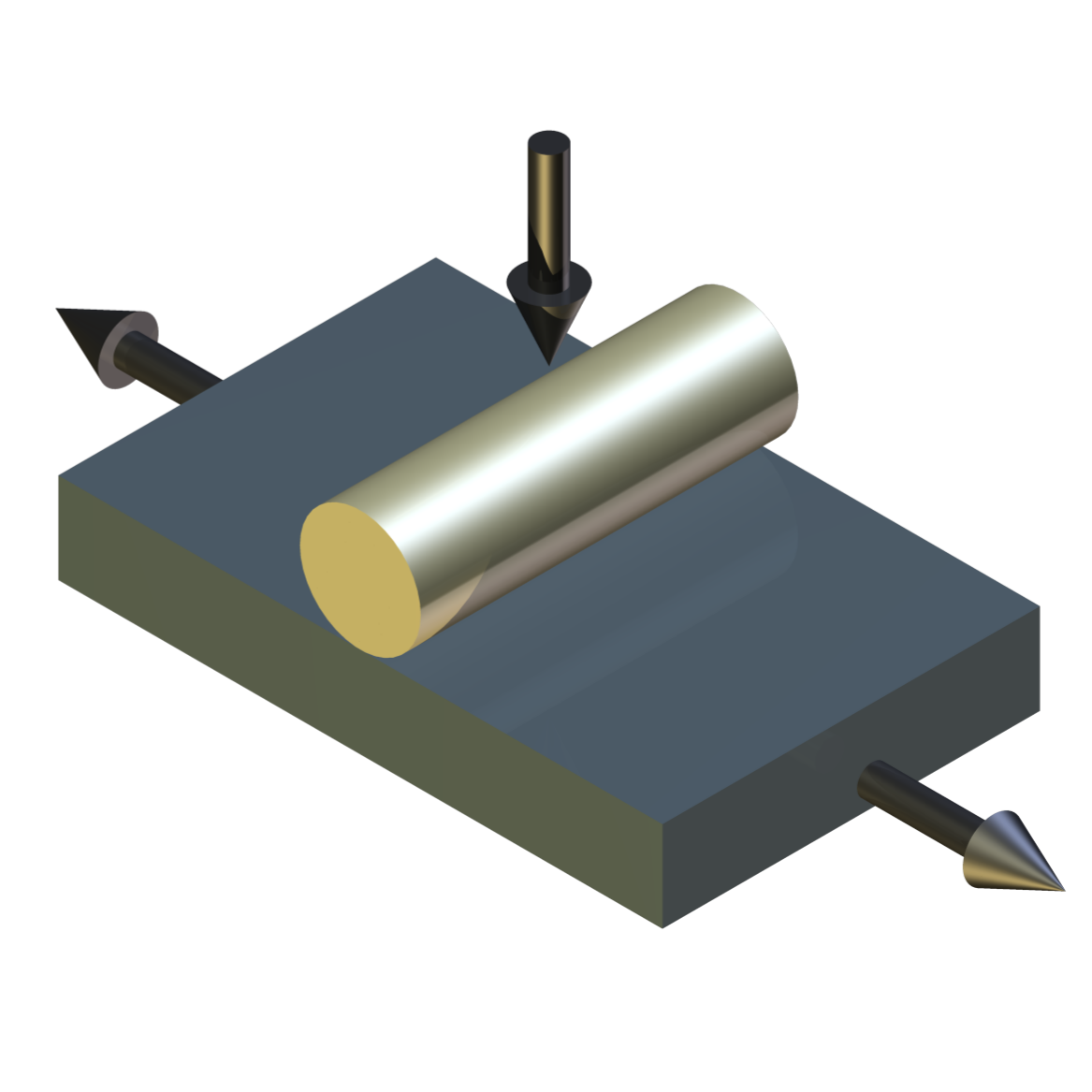

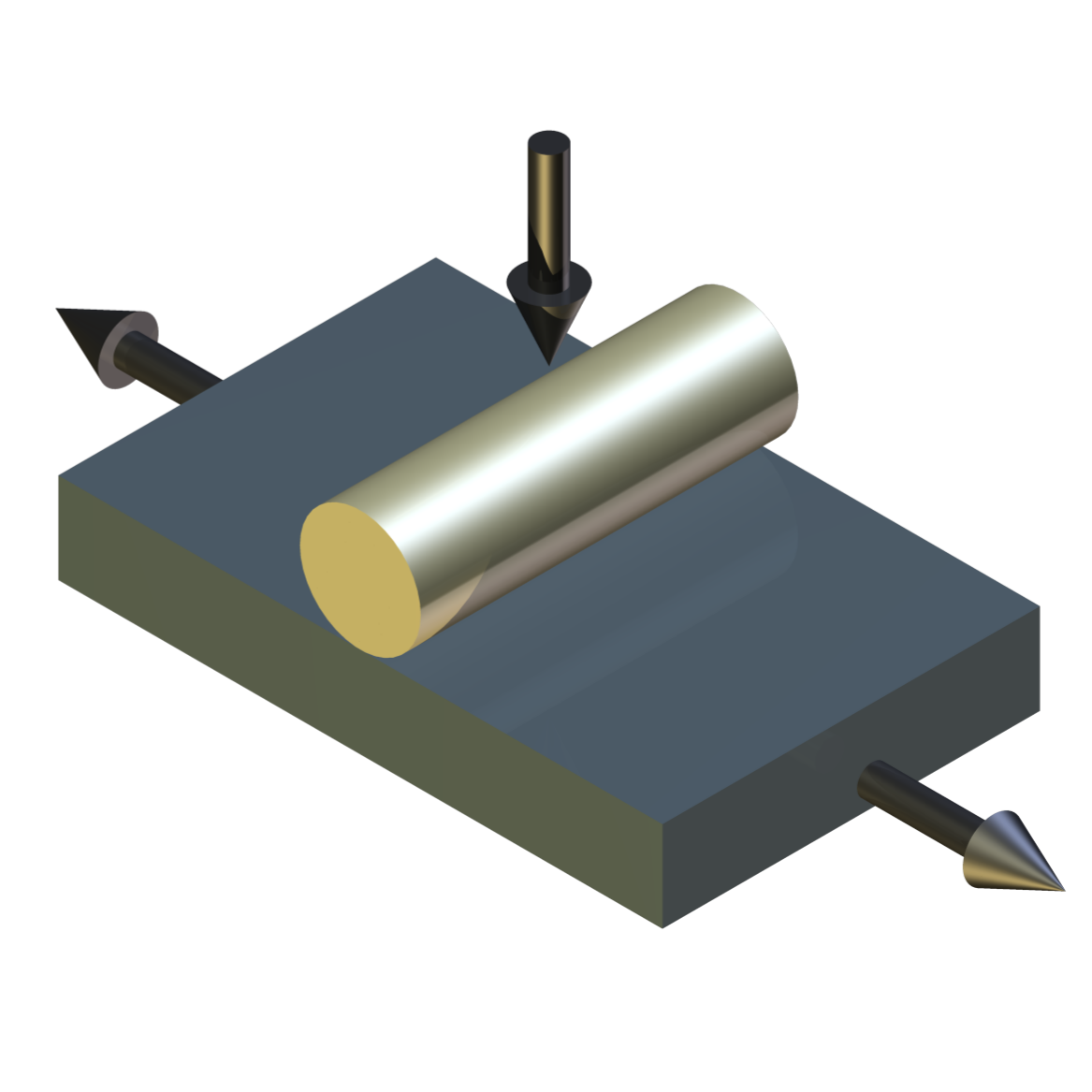

The test assembly, comprises three ball or line contact fixed specimen carrier assemblies, mounted on the top of the pressure vessel. A reciprocating drive projects upwards between the fixed specimen carriers and has locations for three plate specimens.

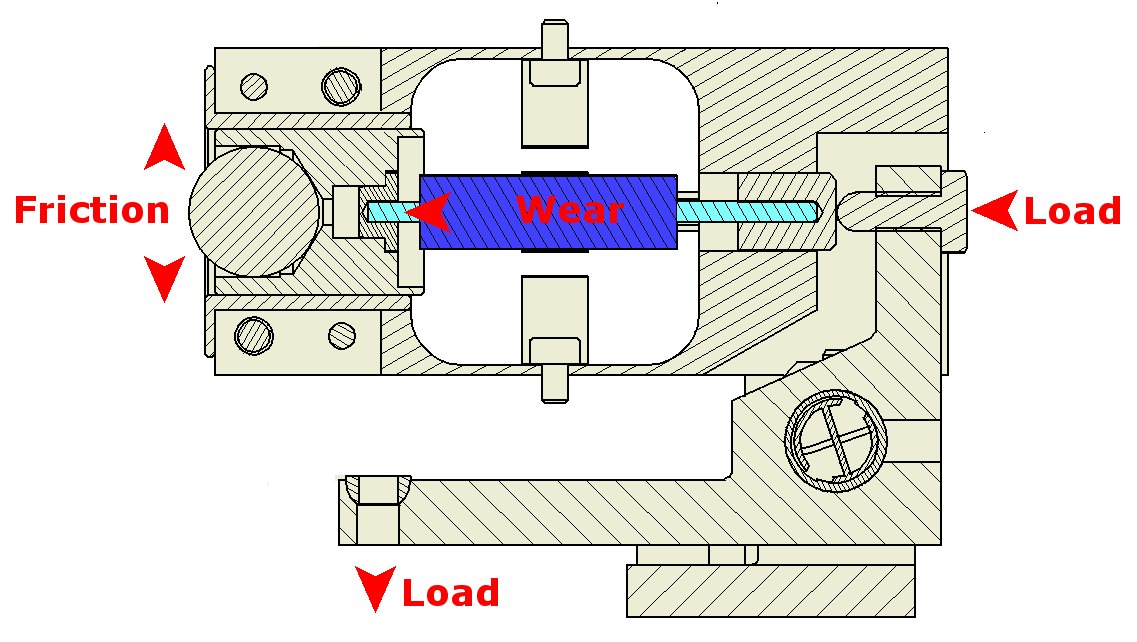

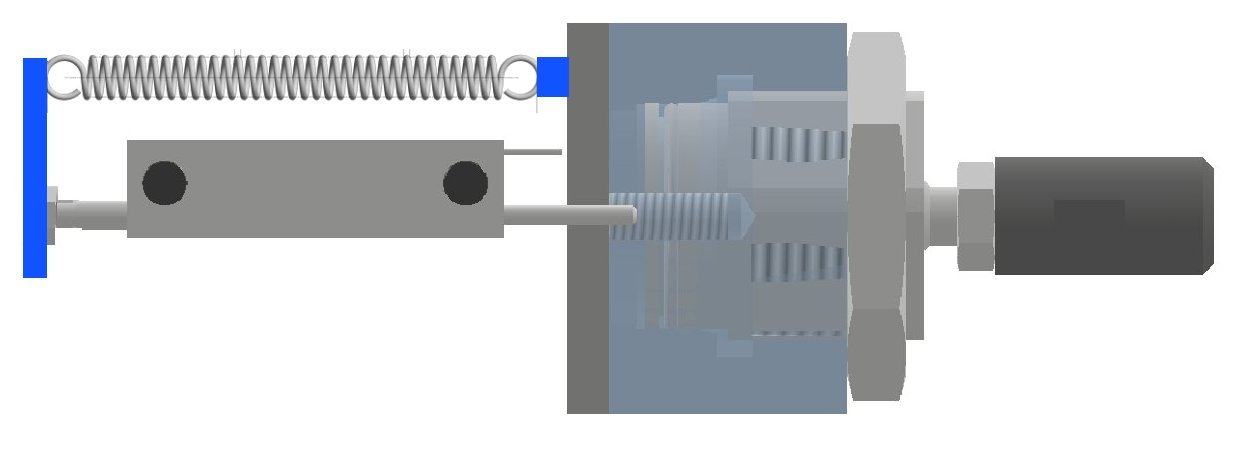

Each fixed specimen is mounted in a combined loading plus friction and wear measuring flexure assembly. Load is applied by pre-tensioning load springs with dead-weights, with the extended springs clamped and the dead-weights removed before the chamber is pressurised. The range is 5 to 100 N.

Friction is measured by the deflection of the cantilevered flexure, with displacement sensed with a hydrogen and high pressure rated LVDT. The range is 0 to 50 N.

Wear is measured with hybrid track linear potentiometer, mounted in the space between the flexure arms and between the load button and the specimen.

Reciprocating motion is generated by a manually adjusted, variable stroke, crank mechanism, a lower chamber. This is driven by an externally mounted, ATex rated, geared servo motor, via a magnetic coupling.

Evacuating, Purging, Charging and Venting

The chamber is supplied fitted with the necessary ports and valves and pressure/vacuum sensors to allow charging of the system. External gas handling and venting systems are not included, but must be installed by the user, in accordance with local standards and safety requirements.

It is recommended that all gas connections are hard plumbed in industry standard stainless steel tubing. It is essential that potentially explosive and asphyxiating gases are safely discharged, outside the laboratory, in accordance with local safety regulations.

The normal procedure for charging is to start by evacuating the chamber, to remove as much air as possible. The chamber is then purged, then pressurised, with nitrogen or inert gas. The purge gas is then vented and evacuated. The chamber is then slowly charged with hydrogen (or other test gas) and the specimens soaked for the required number of hours, before the test is started. At the end of the test, hydrogen is slowly vented from the chamber, if necessary, diluted with nitrogen or inert gas.Peripheral Systems

A cartridge heater and temperature controller are provided for heated tests and a laboratory refrigeration unit with refrigerant probe for cooled tests.

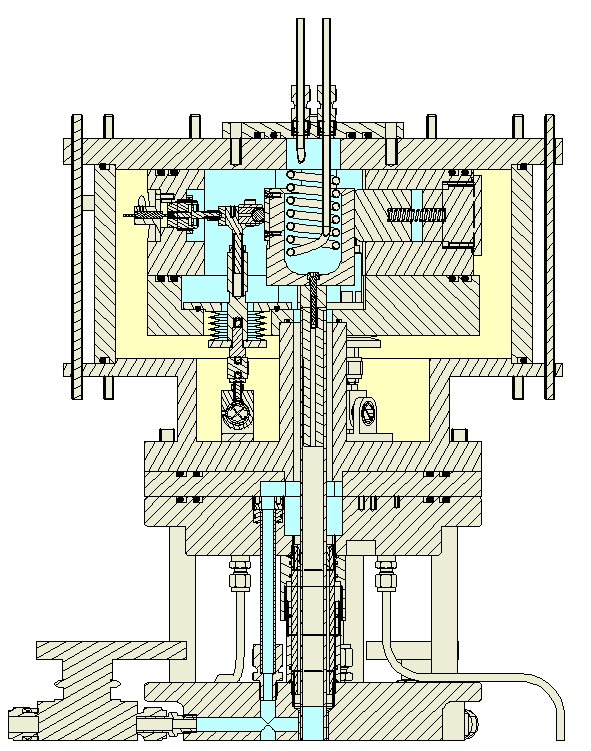

Low Pressure High Temperature Chamber – Under Development

This test assembly fits in place of the standard high-pressure assembly and comprises a double chamber with an inner hydrogen chamber and an outer nitrogen chamber. Specimen load is applied using low-cost and easy to replace pin cylinders. These are mounted in the inner chamber wall, such that a pressure difference between the outer and inner chambers results in the pin cylinder exerting a force on a fixed specimen. A consequence of this arrangement is that the nitrogen pressure is necessarily higher than the hydrogen pressure, during normal operation.

The chosen pin cylinder generates 124.9 N at 7 bar and should produce 150 N at approximately 8.4 bar, hence to achieve a load of 150 N, if the hydrogen chamber were pressurised to 10 bar, the nitrogen chamber would have to be pressurised to 18.4 bar. The N2 chamber is rated for an operating pressure of 20 bar and a proof pressure of 25 bar.

Each fixed specimen is carried on a flexural bearing mounted articulated arm, which is restrained in the direction of the friction force by a piezo force transducer. This allows friction to be measured. The piezo transducer is mounted in the nitrogen chamber, with the articulated arm passing through an edge welded bellows into the hydrogen chamber.

Wear displacement is sensed by monitoring displacement of the pin cylinder piston using a spring-loaded hybrid track linear potentiometer.

Heating of the plate specimens is by bore induction coil, which projects through the chamber lid and into a pocket in the plate specimen carrier. The target maximum temperature is 450°C.Control and Data Acquisition

Control and data acquisition facilities are provided by a PC in conjunction with a Serial Link Interface Module, High Speed Data Acquisition Card and COMPEND control and data acquisition software.

-

Technical Specifications

Technical Specifications Number of Test Stations: Three Test Configuration: Ball on Flat Cylinder on Flat Gases: Hydrogen, Argon, CO2 Working Pressure: 0.1 mbar to 100 bar Proof Pressure: 120 bar Stroke Range: 0 to 20 mm Continuously Adjustable Frequency: 0 to 5 Hz Motion: Sinusoidal Loading System: Tension Spring Load Range: 5 to 100 N Friction Range: 0 to 50 N Deflection Sensor: Inductive Transducer Pressure Rating: 150 bar Refrigerant Probe: Action: Contact cooling of plate specimen Temperature Range: Ambient to -50°C Heating Probe: Action: Contact heating of plate specimen Temperature Range: Ambient to 150°C Electrical Feedthroughs: PT100 x 2 Rotary Feedthough: BMD-300 Magnetic Coupling Motor: NX-210 a.c. Servo Motor Automatically Controlled Parameters Frequency Plate specimen temperature Test duration Manually Controlled Parameters Load Stroke Chamber pressure (external service) Measured Parameters Friction Plate specimen temperature Chamber temperature Chamber pressure Number of cycles Derived Parameters Friction coefficient Services Electricity: 220/240V, single phase 50/60 Hz, 7.5 kW Process Gas System: Not included ATex Rating The machine, drive motor and associated instrumentation are ATex rated. The chiller unit, vacuum pump, power module and PC control and data acquisition system are not ATex rated. It follows that these items must be installed outside any ATex rated test cell, with suitable ATex rated connections between the operator work-station and the test cell. -

Overview Videos

Machine Overview

-

Index Tags

-

Download the Machine Leaflet