-

Description

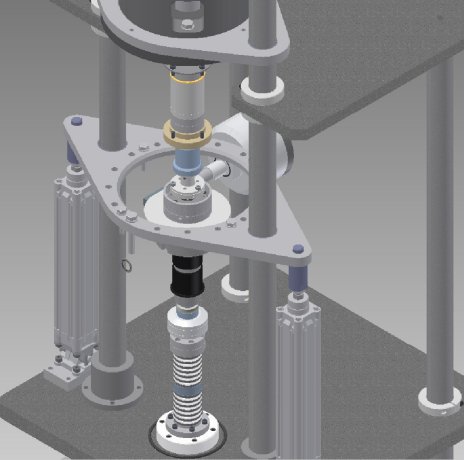

The TE 58 is a hermetically sealed high-pressure rotary tribometer, designed to operate at pressures up to 15 MPa with conventional refrigerants or CO2 as the pressurizing gas/fluid.

The TE 58 has servo controlled loading with force transducer feedback, servo motor with encoder feedback for speed control, SUPERSLIM Serial Link Interface Module and COMPEND 2000 Window compatible control and data acquisition software. The machine is floor-standing.

Motor and Test Spindle

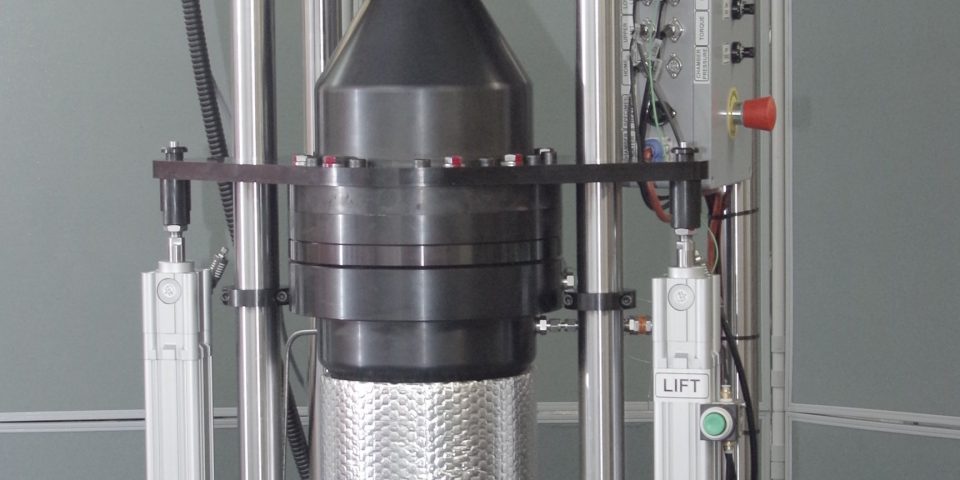

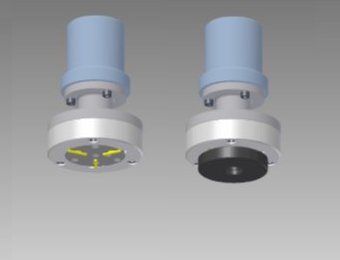

The test spindle, which projects downwards, is fully enclosed within the pressure vessel and incorporates hybrid bearings that run in the working atmosphere. The spindle is connected to the drive motor via a magnetic drive coupling. Moving specimen tooling is attached to the lower end of the spindle.

Load Application and Measurement

Load is applied by means of a servo controlled ball screw actuator, mounted beneath the pressure vessel. A rod extension projects upwards into the vessel and is sealed by means of a high pressure stainless steel bellows. The ball screw actuator thus has to have the capacity not only to apply the required load within the vessel, but also to overcome the pressure forces acting on the bellows.

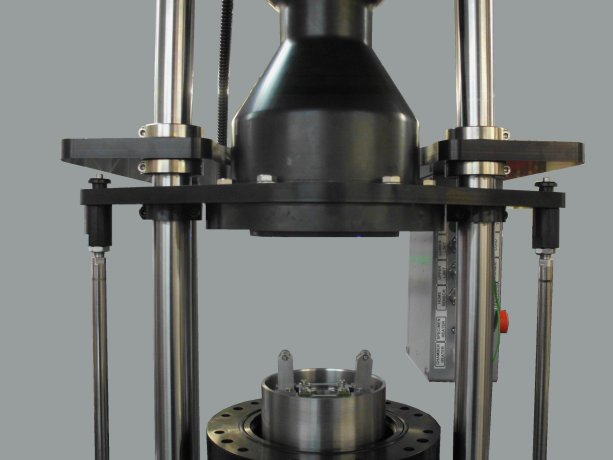

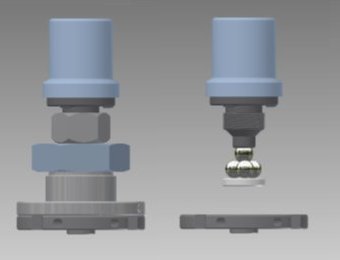

A pressure compensated force transducer is mounted on the upper end of the rod extension, within the pressure vessel. The transducer is connected to a spring-pack of Belleville washers. As the rod is moved upwards and the specimens are brought into contact, the spring washers are compressed, resulting in a load on the specimens; this is detected by the force transducer.

Fixed Specimen Assemblies and Friction Torque Measurement

The fixed test assemblies are torque reaction mounted on top of the spring-pack assembly. Friction torque is measured by means of a torque arm connected to a pressure compensated force transducer.

Access to Test Assemblies

In order to gain access to the test assemblies, the chamber is split at its mid-point and the upper half of the chamber then raised on pneumatic bellows. Standard ports are provided for charging and scavenging the chamber.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.Test Adapters

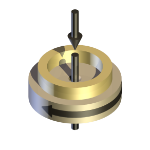

Sliding Four Ball Assembly

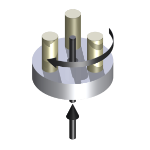

Three Pin /Ball on Disc

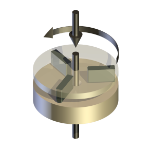

Vane Pump Assembly

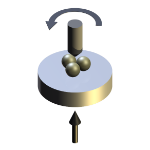

Thrust Washer Assembly

-

Technical Specifications

Maximum Torque: 10 Nm Maximum Load: 5000 N Maximum Pressure: 15 MPa Maximum Speed: 2000 rpm Maximum Temperature: 120 C Environment: CO2, R407, R410 Motion: Continuous sliding Interface: Phoenix Tribology USB micro-controller interface Software: COMPEND 2020 Controlled Parameters Rotational Speed Temperature Load Test Duration Recorded Parameters Rotational Speed Friction Torque Temperatures Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance Services Electricity: 220/240V, single phase, 50 Hz, 5.5 kW 110/120 V, single phase, 60 Hz, 5.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Applications

ball on disc compressor materials high pressure testing refrigerant lubricants sliding four ball vane pump -

User List

Launched 2014

GMCC China -

Download the Machine Leaflet