-

Description

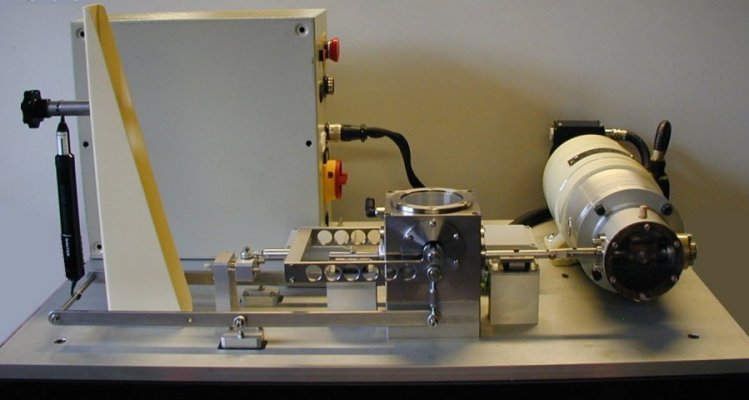

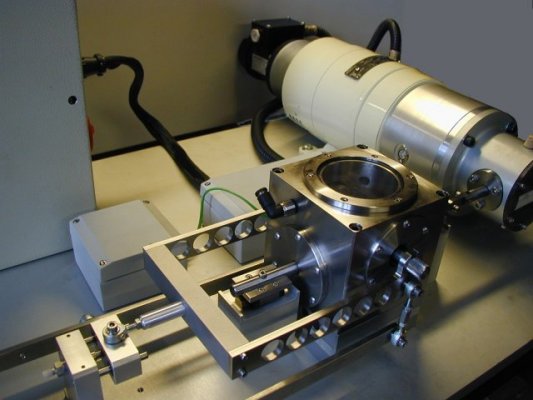

The TE 57 Pressurized Lubricity Tester is a development based the standard TE 77 High Frequency Friction Machine. It incorporates a pressurized test enclosure with moving parts sealed by stainless steel bellows.

Load is applied manually by means of a linkage mechanism acting through transverse bellows. The complete test assembly may be removed from the test machine for cleaning purposes. The unit incorporates a standard SUPERSLIM interface and COMPEND 2000 sequence programmable control and data acquisition software.

-

Technical Specifications

Contact Geometry: Ball on Plate Cylinder on Plate Ball Specimen: 6 mm and 10 mm diameter Load: 10 to 100 N Stroke: Mechanically set 1 to 5 mm Frequency: 2.5 Hz to 50 Hz Chamber Pressure: 4 bar maximum Temperature: ambient to 150°C Computer Controlled Parameters Frequency Temperature Test Duration Manually Controlled Parameters Load Stroke Length Enclosure Pressure Measured Parameters Friction Temperature Contact Potential Frequency Enclosure Pressure Services Electricity: 220/240 V, single phase, 50 Hz, 1.2 kW 110/120 V, single phase, 60 Hz, 1.2 kW Installation Bench-mounting machine: 720 mm x 440 mm x 570 mm high, 80 kg Bench-mounting cabinet: 530 mm x 420 mm x 300 mm high, 30 kg Packing Specification: 1.73 m3, GW 338 kg, NW 240 kg -

Applications

diesel fuel lubricity fuel lubricity refrigerant lubricants -

Publications

Paper # 365 In-use Tribological Analysis of Hydrocarbon Refrigerants applied to the Hermetic Compressor. Garland N and Hadfield M, Proceedings of the second International Conference on Tribology in Environmental Design, Bournemouth, Professional Engineering Publishing, ISBN 1-86058-415-2, pp. 193-203. Paper # 744 Alternative Lining Material Testing for Lifeboat Slipways B Thomas, M Hadfield Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology. (Submitted 2010) Paper # 817 Experimental Sliding Performance of Composite Tip Seal with High-Carbon Steel Plate under Lubricated Conditions Applied to Scroll Expander Systems I Tzanakis, M Hadfield, I Henshaw Tribology Transactions Volume 54, Issue 4, 2011 Paper # 1001 Environmental implications of hydrocarbon refrigerants applied to the hermetic compressors NP Garland, M Hadfield Materials and Design 26 (2005) 578–586 Paper # 1065 The depletion of ZDDP additives within marine lubricants and associated cylinder liner wear in RNLI lifeboat engines M Anand, M Hadfield, B Thomas, R Cantrill Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, First Published 19 Aug 2016 Paper # 1164 Experimental analysis and modelling for reciprocating wear behaviour of nanocomposite coatings MH Nazir, ZA Khan, A Saeed, V Bakolas, W Braun Wear Volumes 416-417, 15 December 2018, Pages 89-102 Paper # 1316 Friction and wear performance analysis of hydrofluoroether-7000 refrigerant MU Bhutta, ZA Khan Tribology International, 2019 – Elsevier Paper # 1317 Wear Performance Analysis of Ni–Al2O3 Nanocomposite Coatings under Nonconventional Lubrication M Bhutta, Z Khan, N Garland Materials, 2019 – mdpi.com Paper #1351 Wear and friction performance evaluation of nickel based nanocomposite coatings under refrigerant lubrication MU Bhutta, ZA Khan Tribology International – 2020 – Elsevier -

User List

Launched 2002

Bournemouth University UK -

Download the Machine Leaflet