-

Description

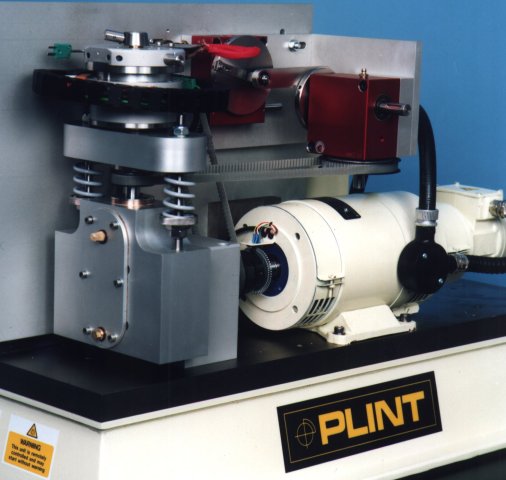

The contact between the ring and the piston groove can give rise to problems of wear, scuffing, micro-welding and, in severe cases, seizure. The TE 34 Piston Ring Micro-Welding Rig may be used for simulating this contact.

A motor driven, vertical axis, cam drive with a stroke of 3 mm, provides vertical reciprocation of a Ring Specimen Holder at a maximum frequency of 20 Hz. The Piston Specimen Holder is placed above the Ring Holder and locates on two linear shafts, restrained by springs. When the Ring Specimen strikes the Piston Specimen, the springs compress to provide the loading on the interface. The peak load is adjusted by pre-setting the spring compression.

The Upper Piston Specimen Holder is connected to a second motor drive shaft via gearboxes and a crank mechanism. This system imposes a +/- 90 degrees rotation on the Piston Specimen, at a maximum of 0.2 Hz. The specimens are thus subjected to a combination of impact and relative rotary motion.

Both the Holders incorporate heaters to permit the temperature of the specimens to be controlled, with thermocouples for feedback to PID controllers. A test oil catching reservoir is provided underneath the Ring Sample Holder. Means of feeding the lubricant into the contact is not included, however, access is provided for either drip feed or oil mist delivery of lubricant samples.

-

Technical Specifications

Technical Specification Ring Diameter: Up to 99 mm Peak Applied Load: 300 N (adjustable) Ring Sample Stroke: 3 mm Maximum Operating Frequency: 20 Hz maximum Piston Oscillation: +/- 90 degrees at 0.2 Hz maximum Ring Sample Temperature: Up to 300°C Piston Sample Temperature: Up to 300°C Services Electricity: 220/240 V, single phase, 50/60 Hz, 3.2 kW -

Applications

micro-welding piston ring groove piston ring materials -

Publications

-

User List

Launched 2001

Not Disclosed -

Download the Machine Leaflet