-

Description

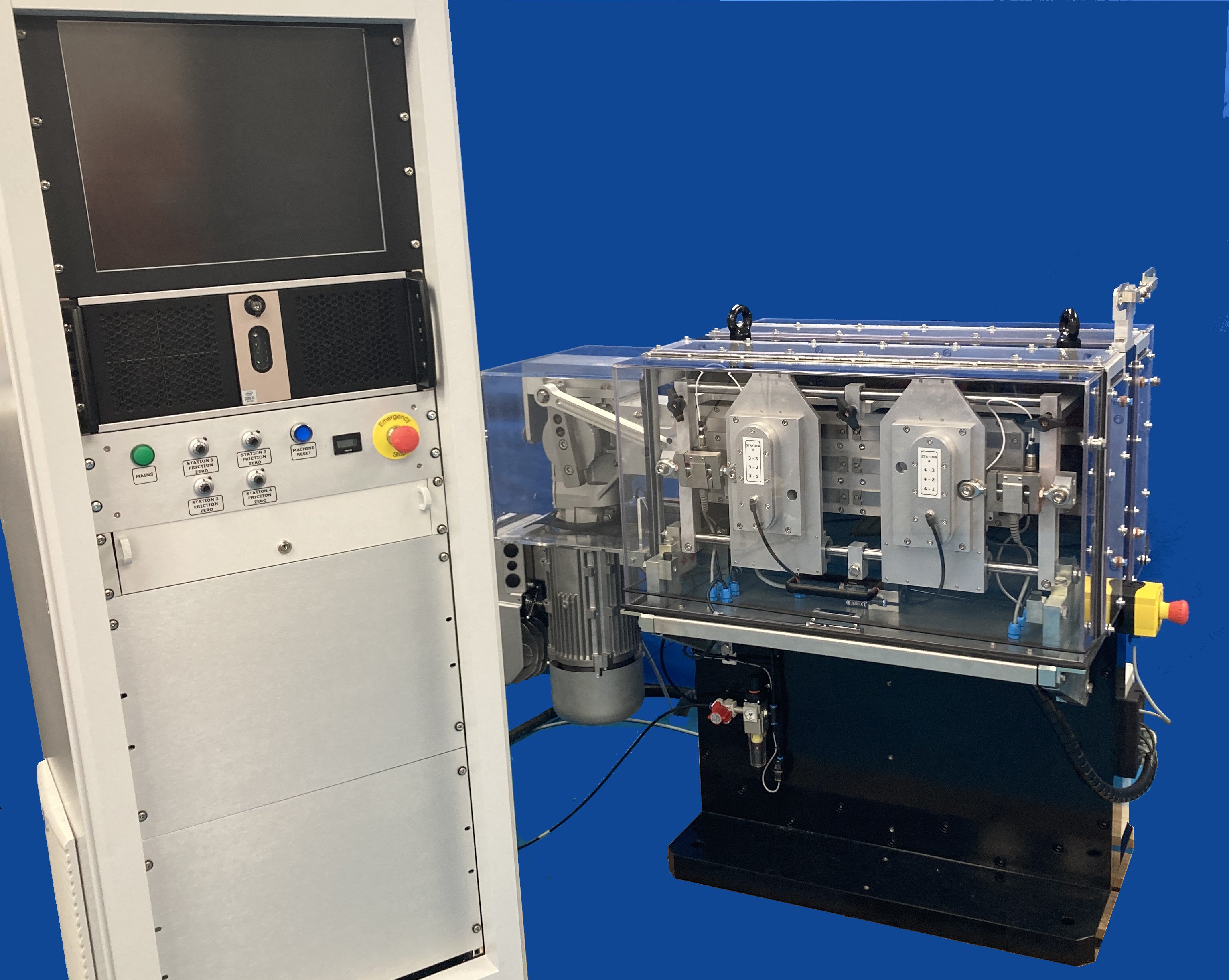

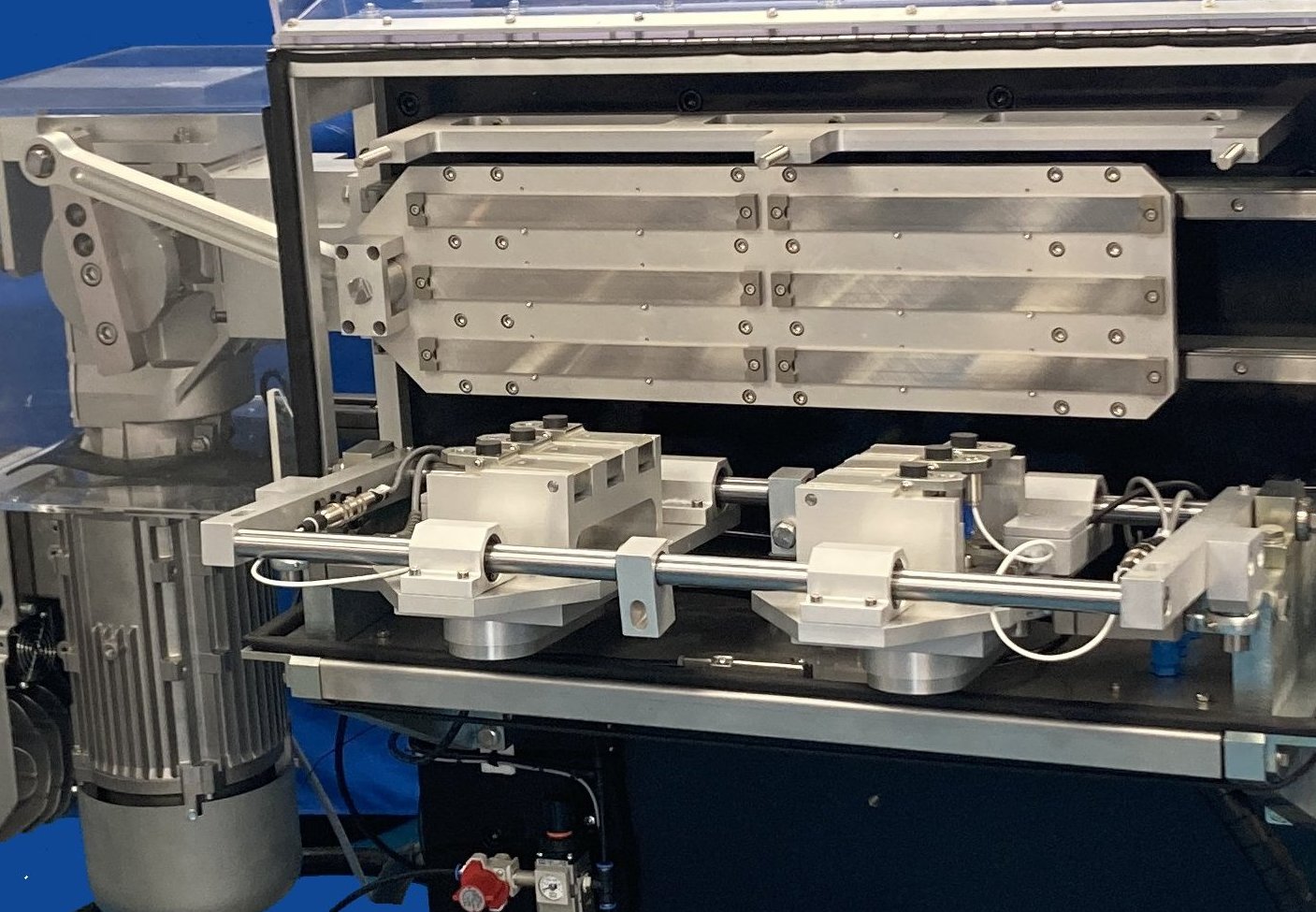

The TE 108 is a twelve-station pin on reciprocating plate machine. The rig comprises a massive “tombstone” base with a gear-motor mounted on one end face. Crank wheels and connecting rods on either side of the gearbox drive reciprocating slides, carrying multiple plate specimens, mounted on either side of the base.

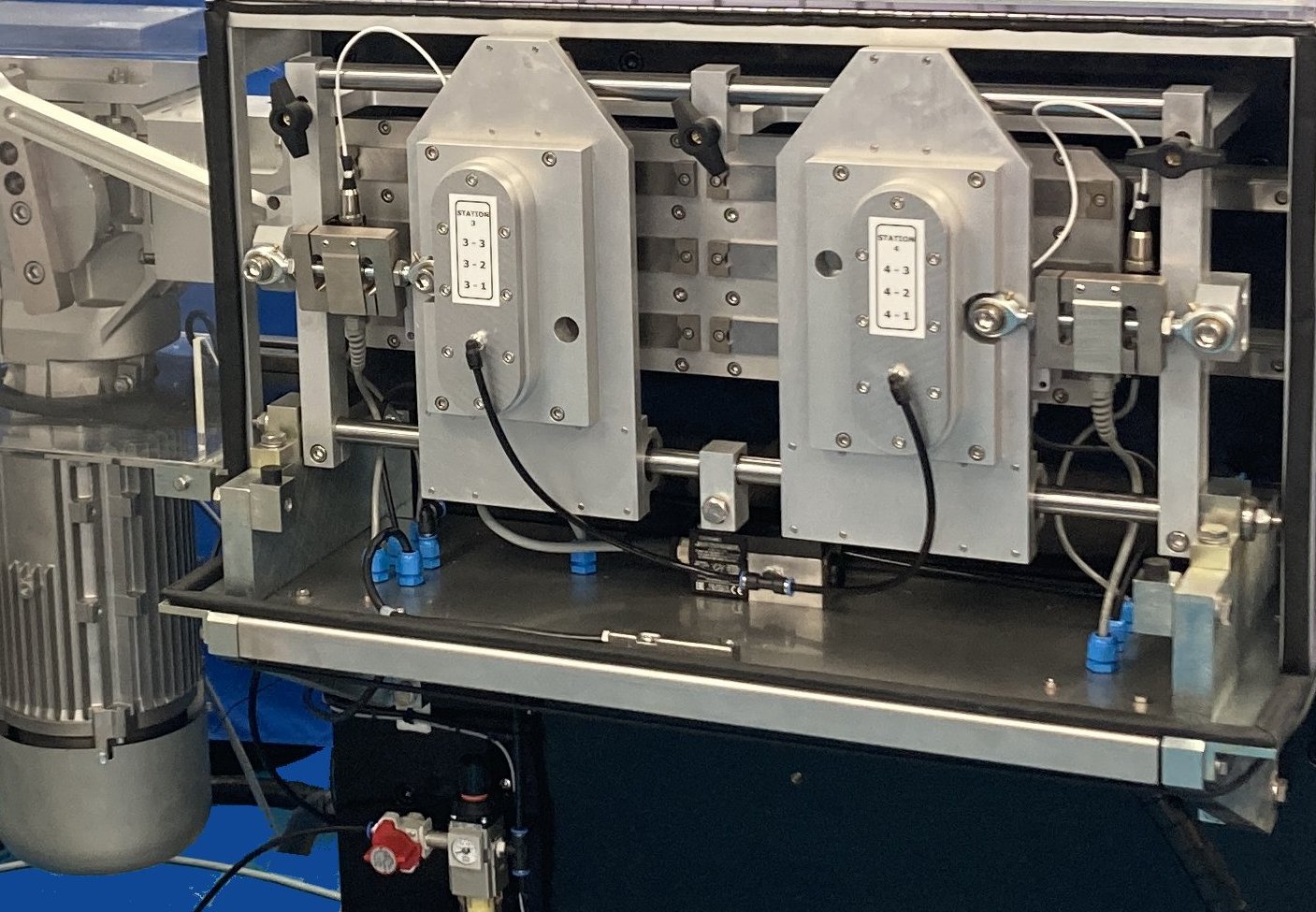

Pin specimens are mounted in lever arms with pivot points perpendicular to the sliding direction. Pin lever assemblies are mounted in groups of three, on separate tracks, to allow each pin to run against its own specimen plate.

The four pin carrier assemblies are mounted on linear bearing rails, with each carrier restrained from movement by a strain gauge force transducer, which senses the total friction force generated by each set of three pins.

Load is applied to each pin using a pin cylinder, with air pressure applied through common manifolds and set by a precision manual pressure regulator. A pressure transducer is provided, calibrated to display the corresponding load. At 8 bar applied pressure each pin cylinder generates a force of 133N.

A precision linear potentiometer is mounted between each pin cylinder and pin specimen to measure the wear displacement.Pyrometers are provided for measuring the plate temperatures.

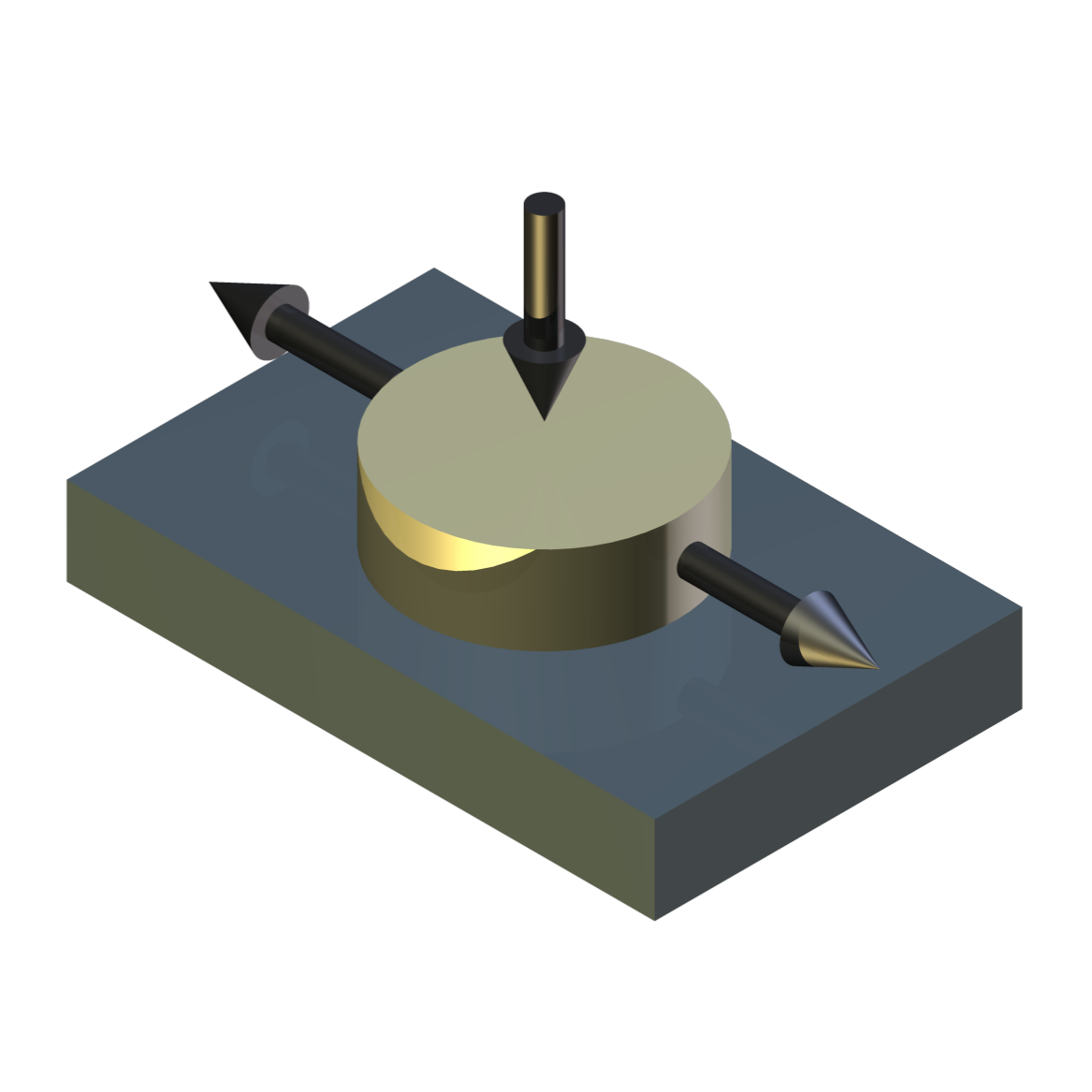

The specimen pins are typically 10 mm diameter and are mounted in self-aligning, hemispherical carriers. Alternatively, hemispherical pins of 18 mm diameter may be used, matching those frequently used on TE 104 High Speed Hydrogen Tribometers.

The maximum stroke is 200 mm, with a maximum reciprocating frequency at 200 mm stroke of 4 Hz, giving a mean sliding speed of 1.6 m/s and a peak sliding speed of 2.5 m/s.

Control and Data Acquisition

The machine is floor standing with integral control unit incorporating a Phoenix Tribology USB Serial Link Interface Module. This is connected to a rack mounted PC with COMPEND sequence control and data acquisition software installed. The system provides sequence control of load, frequency and temperature plus data acquisition of measured parameters.

-

Technical Specifications

Contact Configurations: Area Contact Ball on Flat Area Contact Specimen: Ø10 mm with hemispherical seat (Ø18 mm maximum) Minimum Load: 30 N Maximum Load per Specimen: 133 N @ 8 bar apllied pressure Maximum (total) Friction Force: 500 N Maximum Stroke: 200 mm Maximum Frequency: 4 Hz Load Control: Servo Valve x 2 Load Feedback: Pressure Transducer x 2 Friction Force: Strain Gauge Transducer x 4 Wear Measurement: Linear Potentiometer x 12 Plate Specimen Temperature: Pyrometer x 4 Motor: 7.5kW a.c. Servo Motor and Drive Interface: USB Serial Link Interface Module Software: COMPEND 2000 COMPEND Controlled Parameters

Frequency Test Duration Load (Slide 1) Load (Slide 2) Manually Set Parameters

Reciprocating Stroke Length Measured Parameters

Frequency Test Duration Load x 2 Friction x 4 Wear Displacement x 12 Specimen Plate Temperature x 4 Services

Electricity: 380/415V, three phase 50/60 Hz, 13 kW -

Overview Videos

-

Download the Machine Leaflet