Description

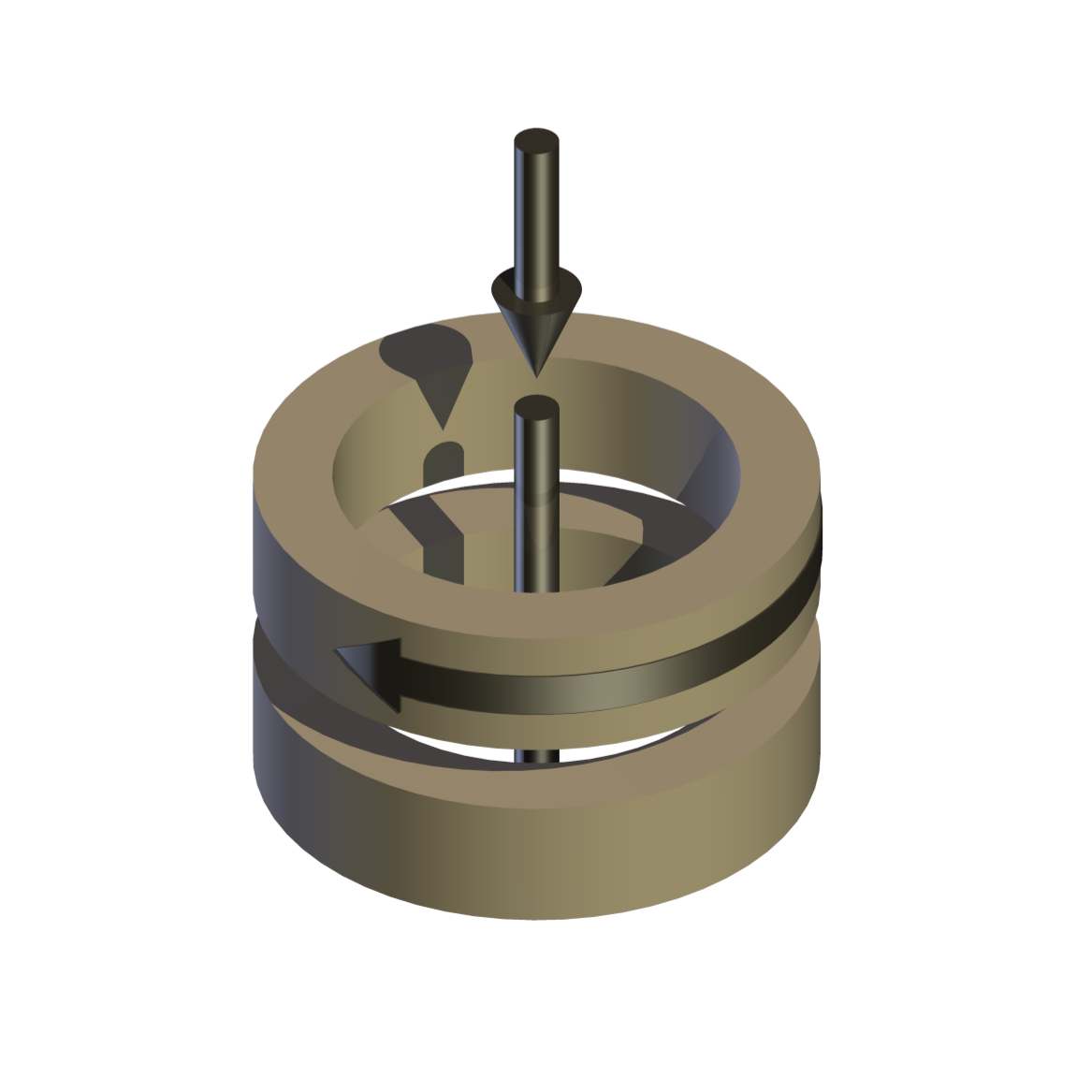

The ST-TC test machine is designed for running tests in accordance with the ASTM G223 standard

for evaluating the friction and adhesive wear properties of materials under both dry and lubricated

conditions. This test bench ensures reliable, standardized testing and facilitates comparative wear

performance analysis for end users.

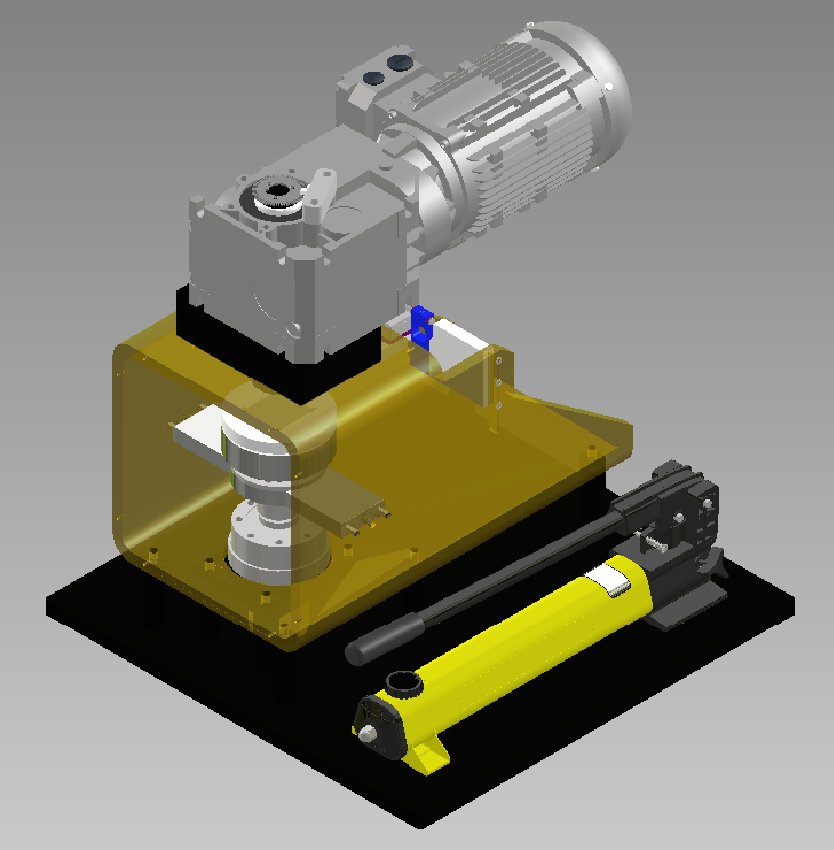

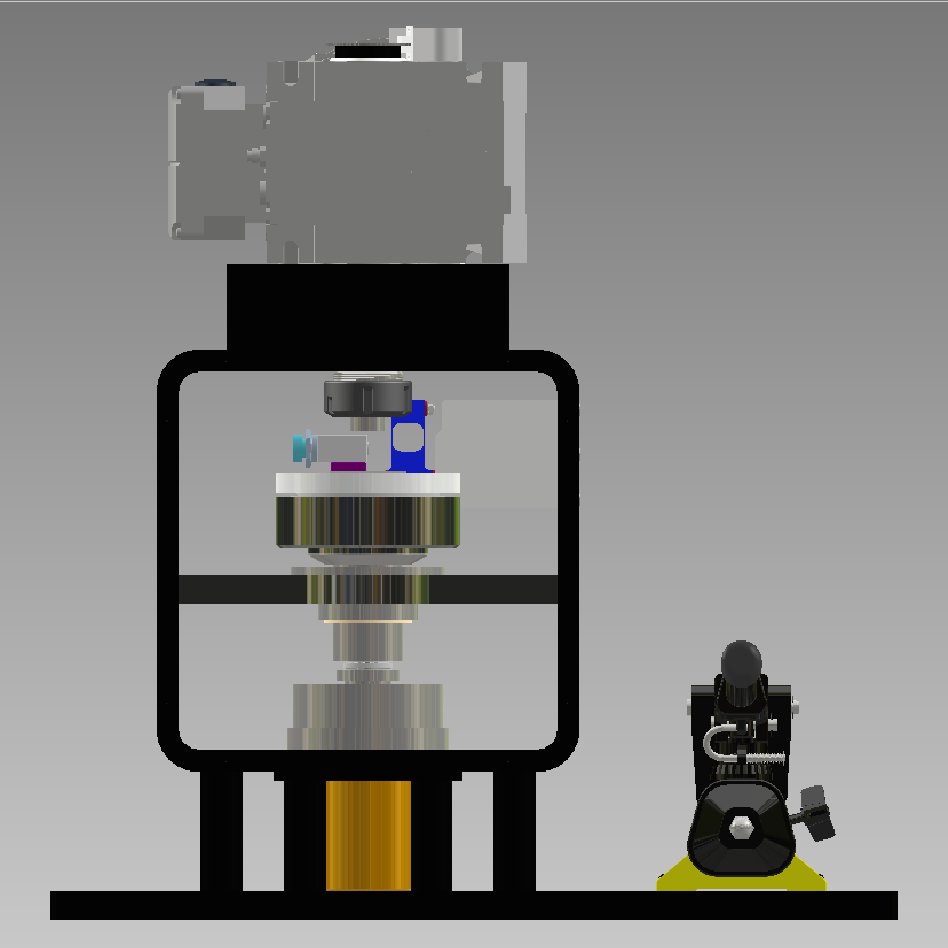

The machine is equipped with a manual hydraulic pump and cylinder for loading, with a force

transducer for load measurement. A high-torque, low speed, gear-motor, with encoder feedback,

provides rotation of the upper specimen. The lower specimen is torque reaction mounted, with a

lever arm that engages with a load cell for friction torque measurement.

The machine frame is designed to be sufficiently rigid to prevent deflection under high test loads.

It features self-aligning mechanisms to ensure horizontal and concentric alignment of the

contacting specimen surfaces.Control and Data Acquisition

Control and data acquisition are implemented via touch screen PLC with friction torque data

exported via USB stick.Standard Tests

ASTM G223 Standard Test Method for Measuring Friction and Adhesive Wear Properties of

Lubricated and Nonlubricated Materials Using the Twist Compression Test (TCT).Order As:

ST -TC TWIST COMPRESSION TESTER

-

Technical Specifications

Hollow Cylinder: 25 mm outer diameter – 3 mm wall thickness Flat Specimen: 40 X 40 mm – 3 mm thickness (can be varied) Load Range: 1.5 to 50 kN Loading Method: Hydraulic Load Measurement: Load cell Load Control: Manual Friction Measurement: Force Transducer Temperature: Ambient Lubrication: Manual Rotational Speed: 0 to 37.4 rpm Motor: 2.6 kW 3 phase a.c. gear-motor Output Torque: 630Nm Control & Data Acquisition: Touch-screen PLC & Interface Data Export: USB Stick Automatically Controlled Parameters

Rotational Speed Test Duration Manually Controlled Parameters

Load Measured Parameters

Rotational Speed Applied Force Friction Force Friction Coefficient Test Duration Services

Electricity: 400 V, 5.5 A, three phase, 87 Hz, 2.6 kW -