-

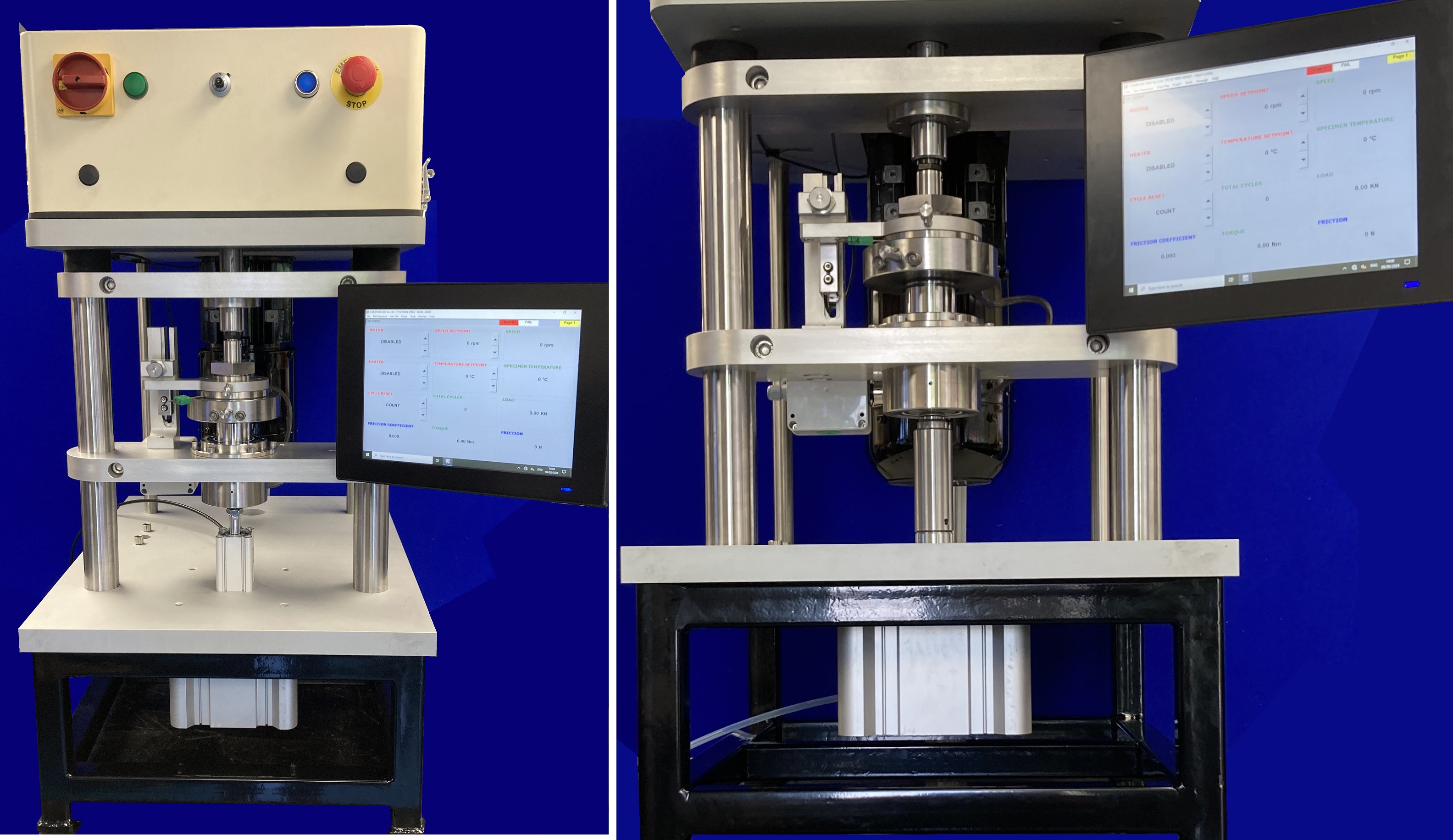

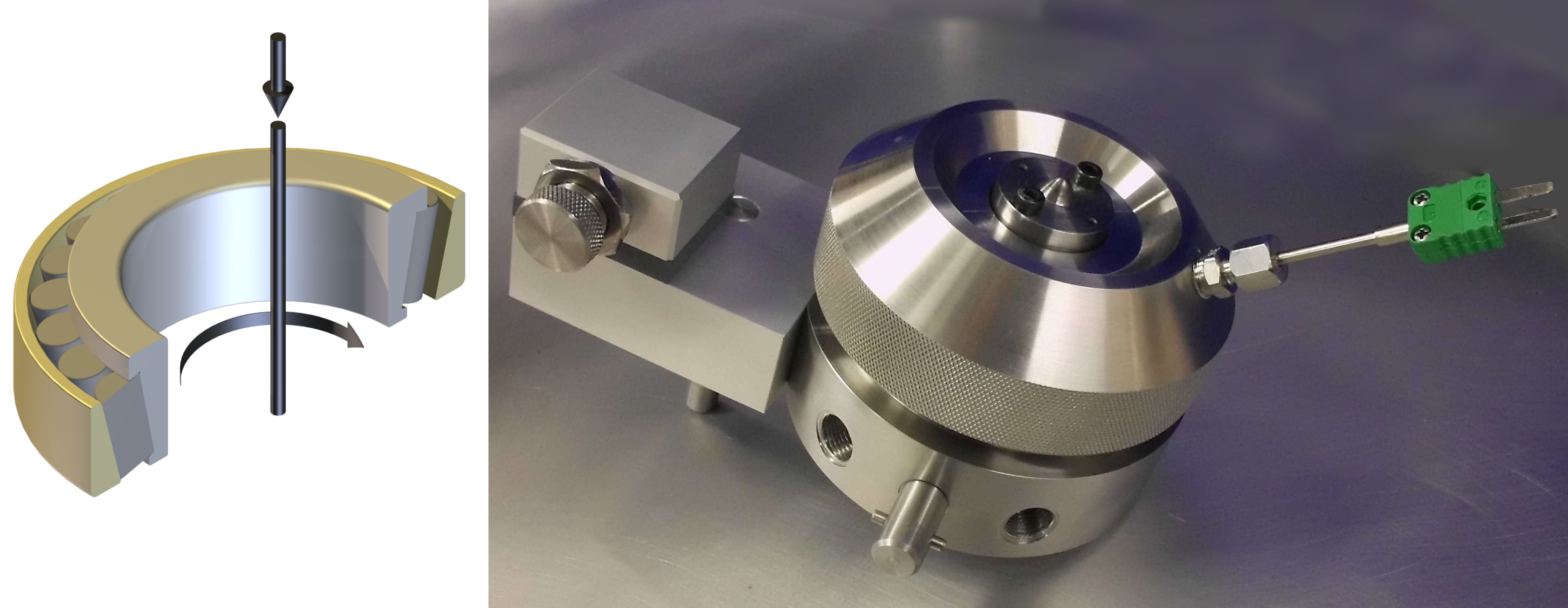

Value engineered tribometer for four ball wear and EP tests

Features

- Touch screen PC for data logging and control of speed and temperature

- Low and high load range pneumatic cylinders

- Precision regulator for manual control of load

- Air bearing mounted load and friction assembly

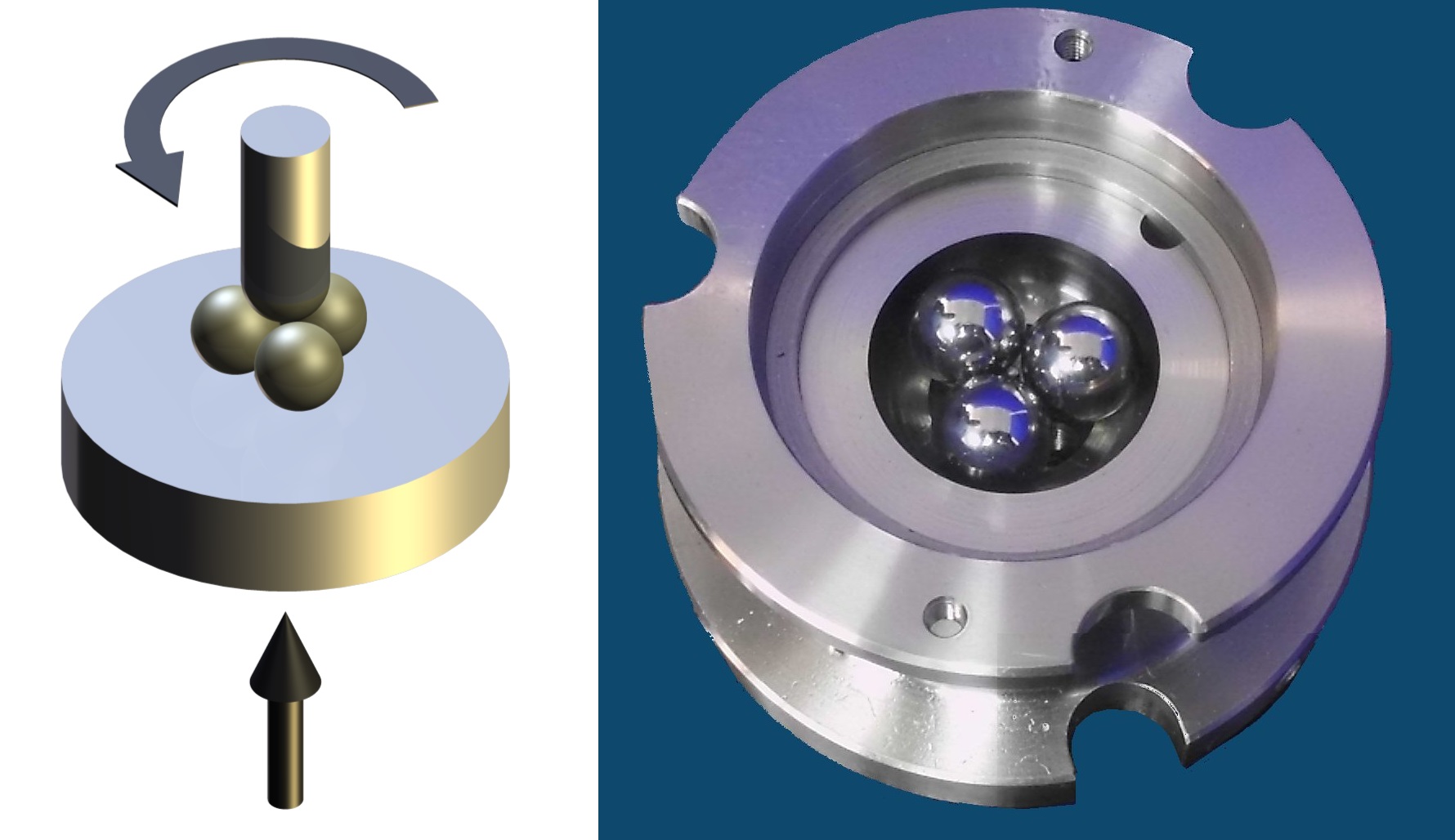

Standard Tests

- ASTM D2266 Wear Preventive Characteristics of Lubricating Greases

- ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid

- ASTM D2596 Extreme Pressure Properties of Lubricating Greases

- ASTM D2783 Extreme Pressure Properties of Lubricating Fluid

- ASTM D5183 Standard Test Method for Determination of the Coefficient of Friction of Lubricants Using the Four-Ball Wear Test Machine

- IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants

- DIN 51350/1-4 Testing Lubricants: Testing in the Shell Four-Ball Tester

- ISO/CD 11008 Petroleum Products and Lubricants – Determination of Extreme Pressure Properties of Lubricating Greases – Four Ball Method

High Resolution Microscope Assembly

- Range 2 mm with 0.01 mm divisions

- Range 4 mm with 0.02 mm divisions

Optional Tests

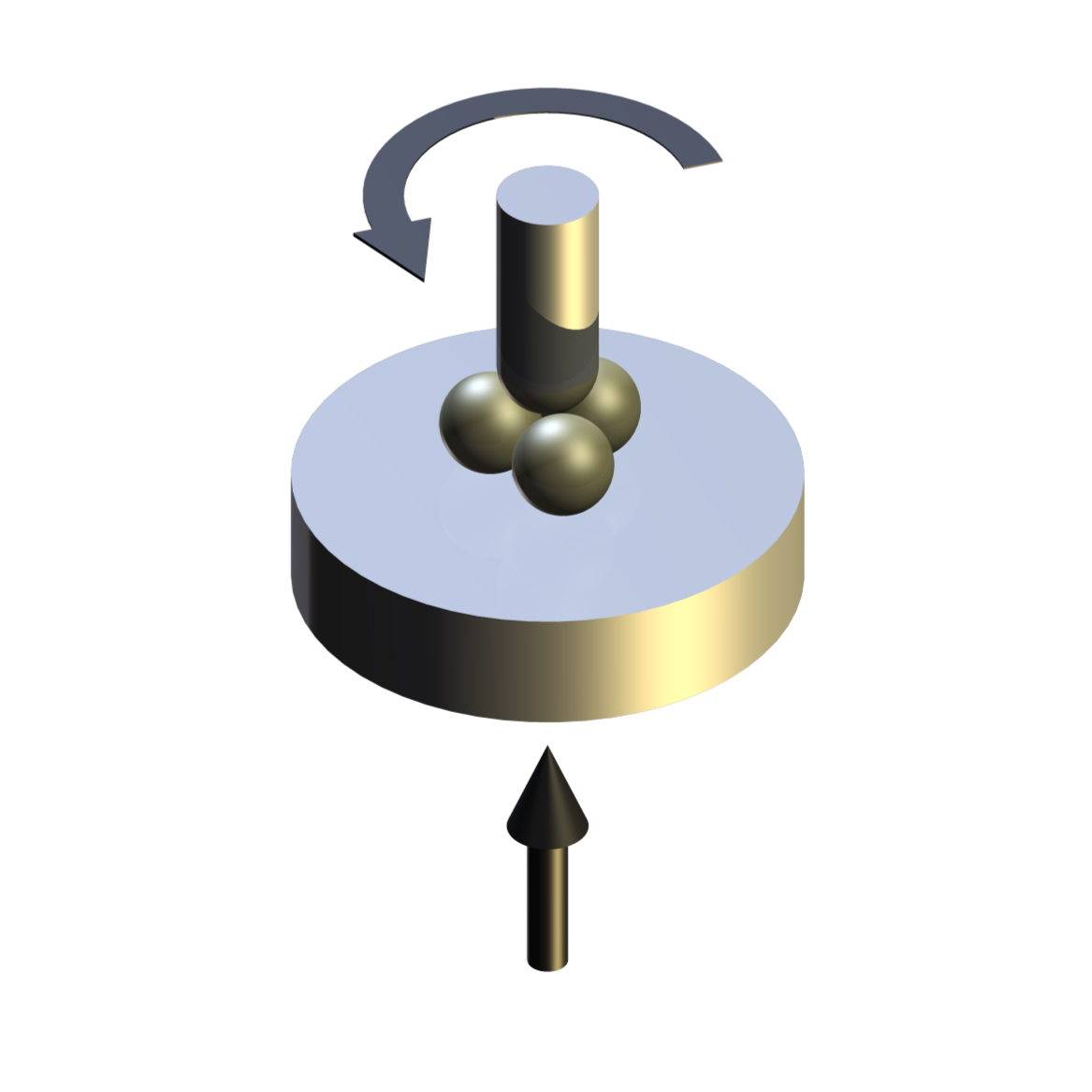

Rolling Four Ball

- IP 300 Rolling Contact Fatigue Tests for Fluids in a Modified Four-Ball Machine

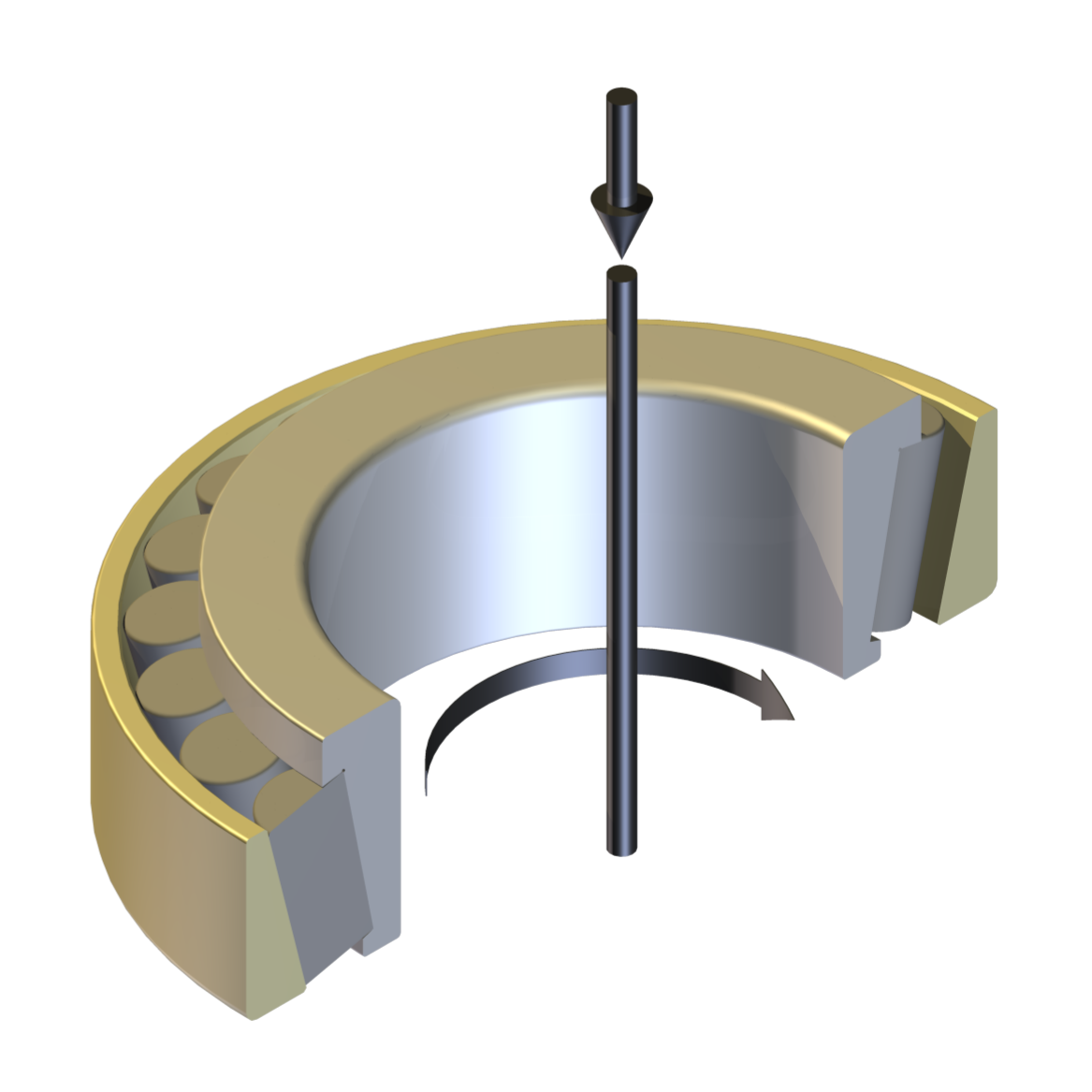

Shear Stability

- DIN 51350/6 Testing of Shear Stability of Lubricating Oils Containing Polymers

- CEC L-45-A-99 Viscosity Shear Stability of Transmission Lubricants (Taper Roller Bearing Rig)

- ISO 26422:2014 Determination of shear stability of lubricating oils containing polymers – Method using a tapered roller bearing

Order as:

- ST-FB Four Ball Wear & Extreme Pressure Test Machine

- ST-FB/DM Digital Microscope with Camera & PC Image Capture Software

- ST-FB/R4B Rolling Four Ball Test Assembly

- ST-FB/KRL Shear Stability Test Adapter

- ST-FB/SM Temperature Control Service Module for KRL Test

-

Technical Specifications Size of Test Balls: 12.7 mm (0.5″) diameter Load Range: 10 to 8,000 N Loading Method: Pneumatic Load Ranges: 20 to 750 N (@ 6 bar air pressure) 50 to 8,000 N (@ 4 bar air pressure) Load Measurement: Pressure transducer Load Control: Precision pressure regulator Friction Measurement: Strain gauge transducer Torque Reaction Mounting: Air bearing Rotational Speed: 60 to 1,800 rpm Temperature Range: Ambient to 200°C Temperature Sensor: k-type thermocouple Motor: 1.5 kW a.c. vector motor Control & Data Acquisition: Touch-screen PC & Interface Data Export: USB Stick Pre-programmed Test Sequences ASTM D2266 Wear Preventive Characteristics of Lubricating Greases ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid ASTM D2596 Extreme Pressure Properties of Lubricating Greases ASTM D2783 Extreme Pressure Properties of Lubricating Fluid IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants DIN 51350/1-5 Testing Lubricants: Testing in the Shell Four-Ball Tester Automatically Controlled Parameters Rotational Speed Temperature Test Duration Manually Controlled Parameters Load Measured Parameters Rotational Speed Load Friction Torque Temperature Test Duration Friction Coefficient Services Electricity: 220/240V, single phase, 50/60 Hz, 3.0 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Overview Videos

Machine Overview

-