-

Description

RCF 4 Rolling Contact Fatigue & Bearing Friction Rig may be used for both endurance testing and precision bearing frictional loss measurement. Two test assemblies are available:

• combined radial and axial loading

• bi-directional axial loading

Load is applied by means of servo controlled pneumatic bellows with force transducer feedback.

An in-line torque transducer is provided for friction measurement, with a maximum permissible speed of 10,000 rpm.

Bearing outer race temperatures are measured with thermocouples and a vibration sensor with adjustable level trigger circuit is provided for stopping the machine at the on-set of rolling contact fatigue.

An integral lubricant service module is fitted as standard incorporating a sump tank with immersion heater, delivery pump, scavenge pump, oil to water heat exchangers for cooling and change-over filters.RCF 4/1 Combined radial and axial loading assembly

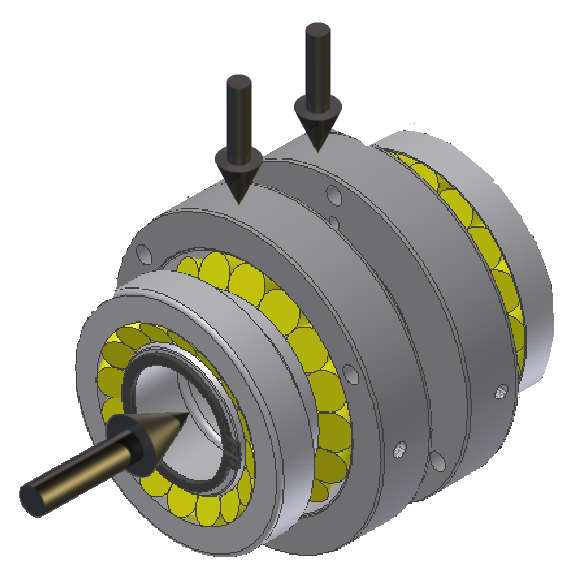

The test assembly for combined radial and axial loading uses four identical bearings mounted in a back-to-back configuration. Taper roller, spherical roller, cylindrical roller, angular contact and deep groove ball bearings can be accommodated, with shaft sizes from 40 mm to 65 mm and a maximum bearing outside diameter 140 mm. The maximum axial load is 16 kN and the maximum radial load per bearing is 40 kN.

RCF 4/2 Bi-directional axial loading assembly

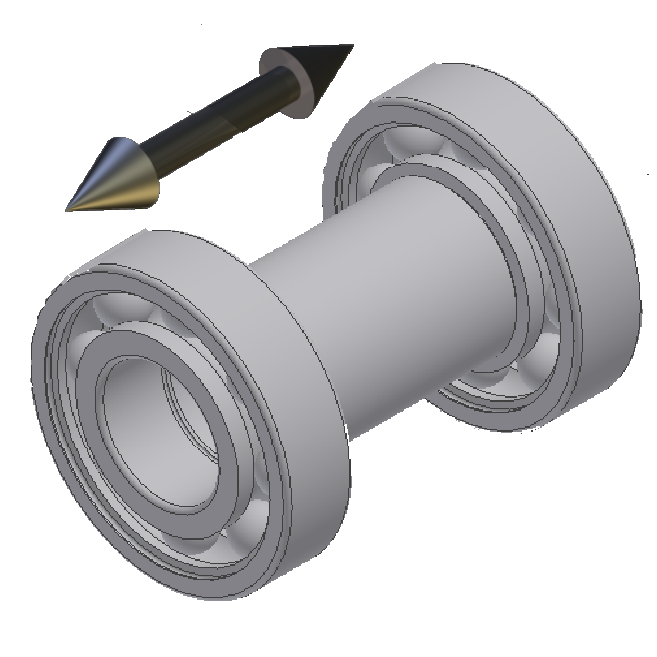

The test assembly for bi-directional axial loading allows two deep grove ball bearings to be mounted, loaded against each other, with a maximum axial load of +/-4 kN. Shaft sizes from 20 mm to 40 mm and a maximum bearing outside diameter 90 mm can be accommodated. Uni-directional loading of angular contact bearings is also possible.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Technical Specifications Motor: 4 kW a.c. vector motor and drive with encoder feedback Maximum Motor Speed: 3,000 rpm High Speed Drive: Flat belt Ratio: 6.7:1 Low Speed Drive: Timing belt Ratio: 1:2 & 2:1 Maximum Spindle Speed: 10,000 rpm Torque Transducer Range: 50 Nm Maximum Lubricant Supply Rate: 6.8 l/min Maximum Lubricant Supply Temperature: Ambient to 150°C Change-over Filters: 3 micron Interface: Phoenix Tribology USB micro-controller interface Software: COMPEND 2020 Controlled Parameters Motor speed Applied loads Test fluid temperature Test duration Recorded Parameters Motor speed Applied load Total bearing friction Lubricant inlet temperature Bearing outer race temperatures Vibration sensor output RCF 4/1 Combined Radial and Axial Loading Configuration: Four bearing back-to-back Bearing Types: Taper, spherical, cylindrical roller, angular contact, deep groove ball Shaft Diameters: 40 mm to 65 mm Maximum Bearing Outside Diameter: 140 mm Maximum Axial Load per Bearing: 16 kN Maximum Radial Load per Bearing: 40 kN Maximum Axial Load: 16 kN Maximum Radial Load: 80 kN RCF 4/2 Test Assembly – Bi-directional Axial Loading Configuration: Two deep grove ball bearings back-to-back Bearing Types: Deep grove and angular contact (uni-directional loading) Shaft Diameters: 20 mm to 40 mm Maximum Bearing Outside Diameter: 90 mm Maximum Axial Load Per Bearing: 4 kN Maximum Axial Load: 4 kN Services Electricity: 415 V, three phase, 50/60 Hz, 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Mains water and drain: 10 l/min (typical) -

Index Tags

-