Description

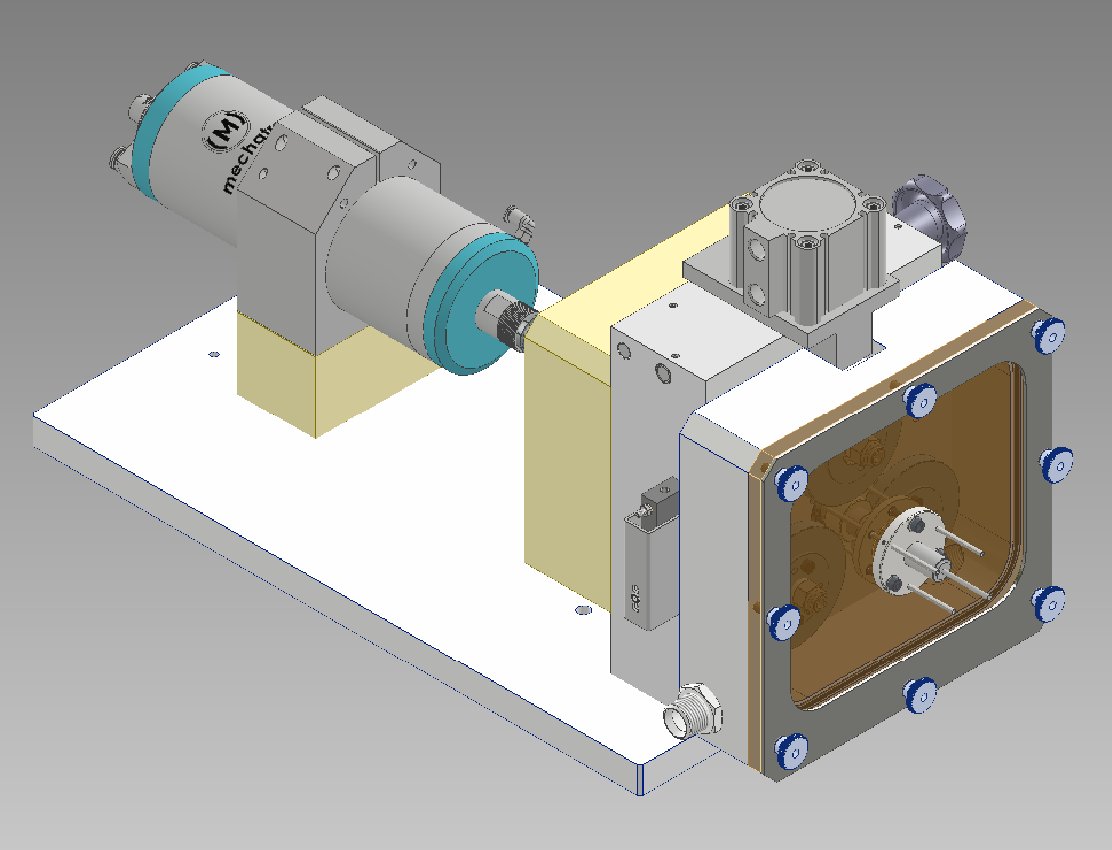

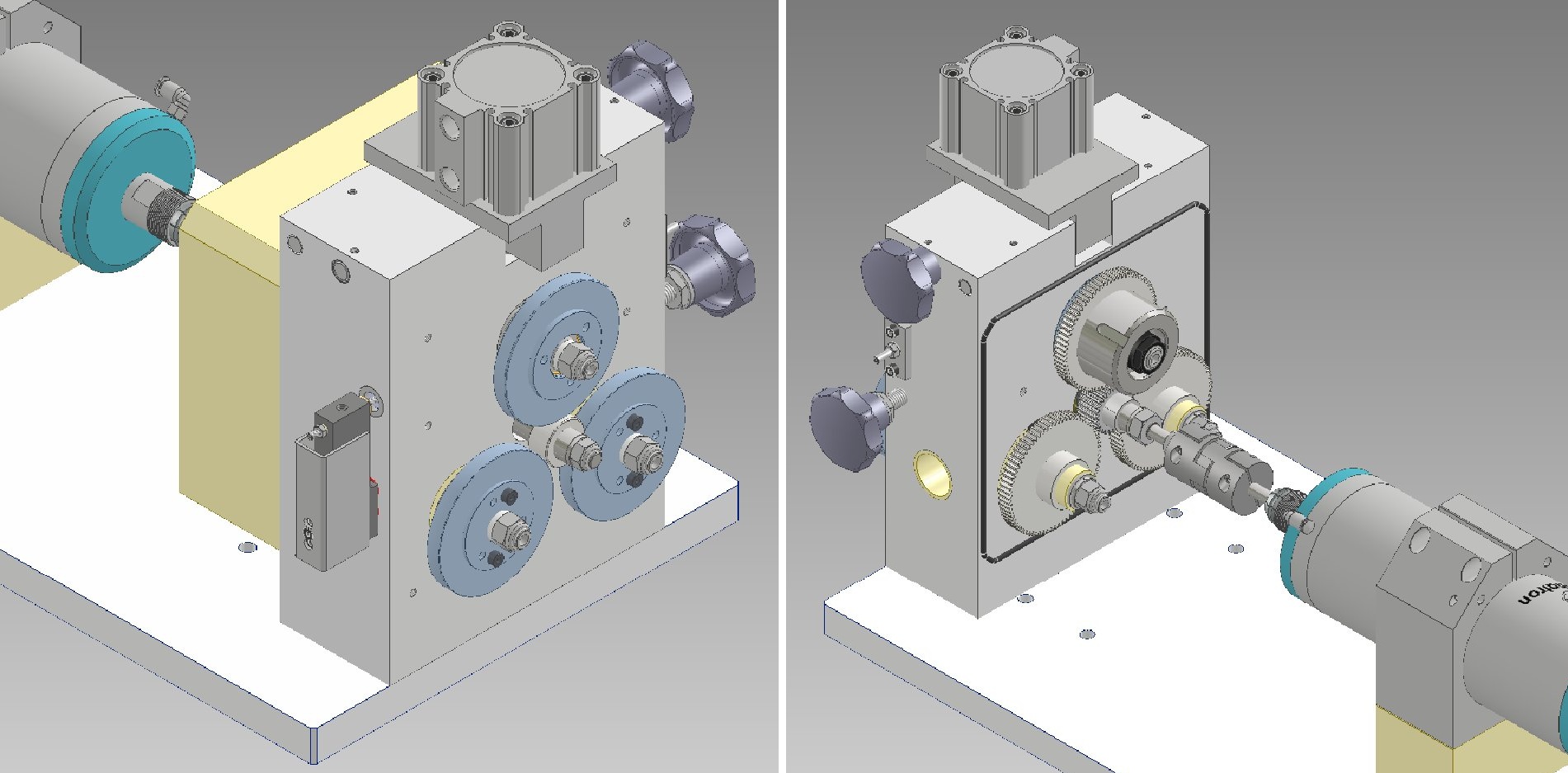

The ST-PR Pitting Rig features a three-disc-on-roller configuration designed to investigate RCF

failure mechanisms, including macro and micro pitting in rolling-sliding contacts under both dry

and lubricated conditions. The test roller specimen is driven by a single motor, utilizing a

circulating torque mechanism with gear pairs, which eliminates the need for high-capacity drive

motors. Different Slide Roll Ratios (SRR) are achieved by selecting the appropriate gear pairs

and/or varying the diameters of the discs and test roller.

Load is applied via a pneumatic cylinder action on the top disc, which is mounted on a floating

shaft. A precision pressure transducer is used to indicate the load, which is then transmitted to

the test roller, which is also mounted on a floating shaft. Finally, the load on the test roller is

transmitted to the lower discs, which are mounted on fixed shafts.

A load cell reacts the horizontal force acting on the upper disc, which is generated by traction

between the test roller and the upper disc.

The two lower discs are electrical insulated and fitted with brushes, allowing electrical contact

measurements between each disc, through the contacts with the roller specimen.Test Configurations

Various disc and test roller geometries can be used to achieve different Hertzian contact pressures

and slide-roll ratios. Test speeds are controlled through a high-speed motor spindle with a

frequency inverter to achieve the desired surface velocity of the discs and rollers. The test

temperature is regulated via a lubrication circulation system with a temperature-controlled

feedback mechanism.Order As:

ST-PR PITTING RIG – THREE DISCS ON ROLLER

-

Technical Specifications

Size of 3 Discs: 62 to 75 mm diameter (each) – can be varied Size of Test Roller: 25 to 38 mm diameter – can be varied Load Range: 0 to 2,000 N Loading Method: Pneumatic Load Measurement: Pressure transducer Load Control: Manual precision pressure regulator Traction Force: Load cell Contact Resistance: Lunn-Furey circuit or LCR circuit Slide Roll Ratio: 0 to ± 30 % – can be varied Surface Velocity of Test Roller: up to 12 m/s Wear Analysis: Optical Screening Rotational Speed of Test Roller: up to 6,000 rpm Temperature Range: Ambient to 150°C Temperature Sensor: k-type thermocouple Motor: 1.5 kW a.c. vector motor with liquid cooling Control & Data Acquisition: PC with COMPEND software and USLIM interface Automatically Controlled Parameters

Rotational Speed Lubricant Temperature Test Duration Manually Controlled Parameters

Load Slide-Roll Ratios Lubrication Flow Rate Measured Parameters

Rotational Speed Load Traction (upper disc – test roller) Electrical Contact Resistance (lower disc – test roller – lower disc) Vibration Signal (uncalibrated) Temperature Test Duration Services

Electricity: 230 V, 6.4 A, 1.5 kW -