Description

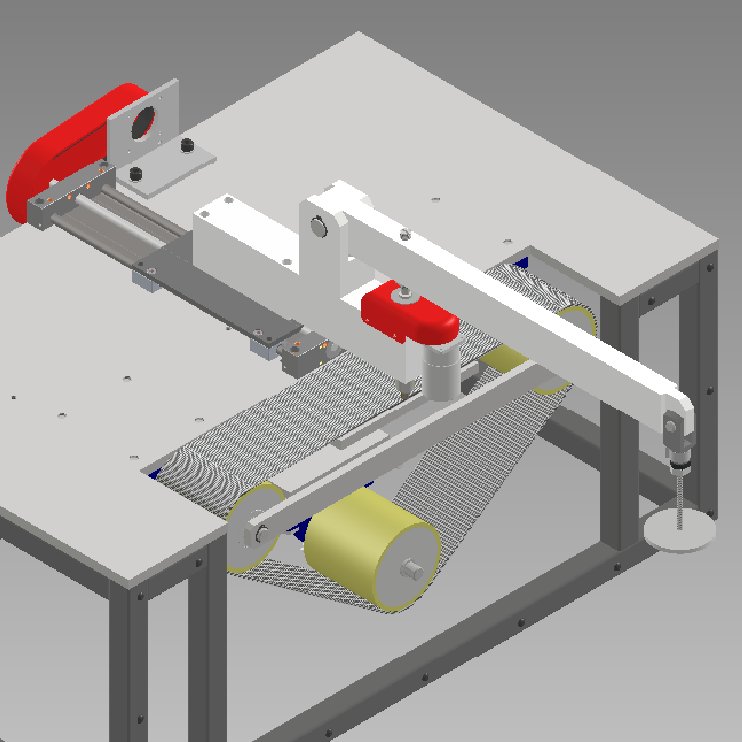

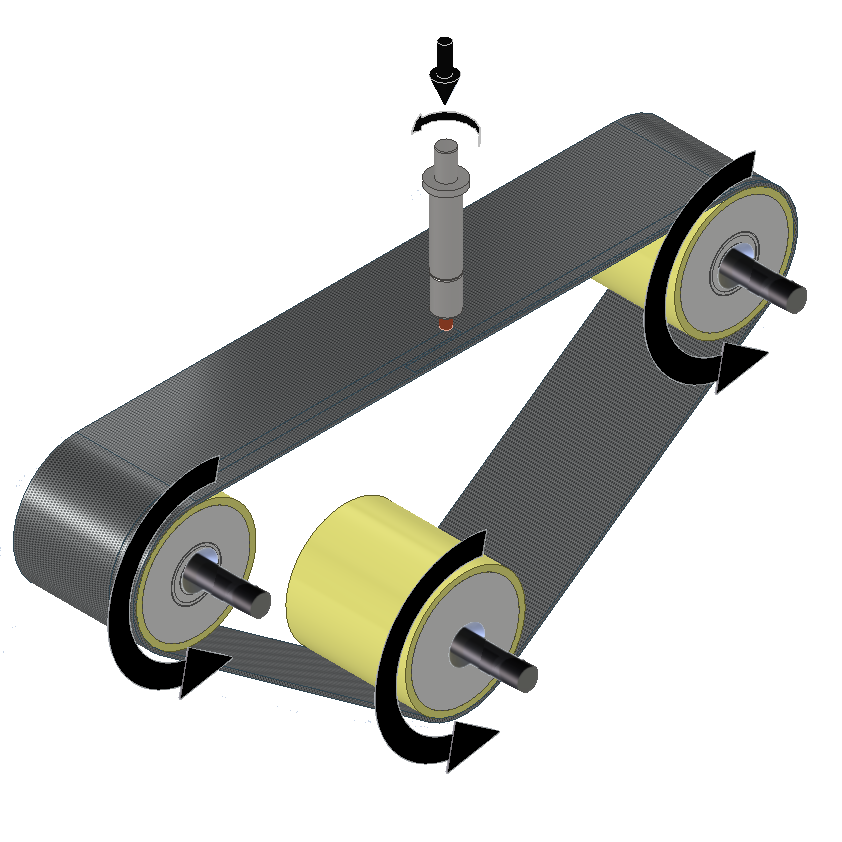

The ST-BA Belt Abrasion Tester utilizes a rotating pin-on-rotating-belt approach to assess the

abrasive wear resistance of materials. In this setup, the rotating pin is pressed against a moving

abrasive belt under a controlled normal load applied via a dead weight, ensuring consistent and

repeatable wear testing. A motorised linear slide mechanism ensures the pin progressively moves

over fresh abrasive material along a prescribed wear track length, closely mimicking real-world

wear conditions.

To maintain accurate test conditions, the drive system regulates the rotational speed of both the

pin and the belt. The indexing slide guides the rotating pin along the belt, ensuring consistent

wear distribution. Successive wear passes are positioned to avoid overlap, allowing the reference

pin to be tested on an unused abrasive path parallel to the test pin’s track.

This setup provides a precise and standardized method for comparing material wear performance.

It is ideal for testing metals, ceramics, polymers, and coatings in research, quality control, and

industrial applications, fully compliant with the ASTM G132 standard.Features

- Belt-driven three-roller disc for abrasive testing with a low-power motor.

- Low-cogging servo motor ensures precise test pin tracking.

- PLC-controlled test configuration for accuracy and automation.

Standard Tests

- ASTM G132 Standard Test Method for Pin Abrasion Testing

-

Technical Specifications

Pin: 2 – 10 mm diameter Pin Rotational Speed: 15 – 50 rpm Maximum Load: 200N (dead-weight) Nominal Contact Pressure: 1 – 2.5 MPa Sliding Speed: 10 – 100 ms-1 Wear Path Length: 4 – 10 m Belt Width: 100 mm Belt Length: 1,200 – 2,000 mm Abrasive: 150 grit garnet Alternate Abrasives: 80 – 220 grit Belt Drive: d.c. geared motor Pin Drive: d.c. geared motor Indexing Drive: a.c. servo-motor Temperature : Ambient Control and Automation: Touch-screen PLC & Interface Automatically Controlled Parameters

:

Pin Rotational Speed Sliding Speed Test Duration Manually Controlled Parameters Load Post-Test Analysis

Material Wear Loss Wear Rate Wear Track Profile Comparative Material Performance Services

Electricity: Belt Drive: 24 VDC, 17.2 A, 10 Nm, 102 W Pin Drive: 12 VDC, 10 Ncm Indexing Drive: 230 V, 1.1 A, 3.4 Nm (peak) -