-

Description

This device appears as Device Number 211 in the ASLE Friction and Wear devices book and was

originally developed by NTN in the 1960s.

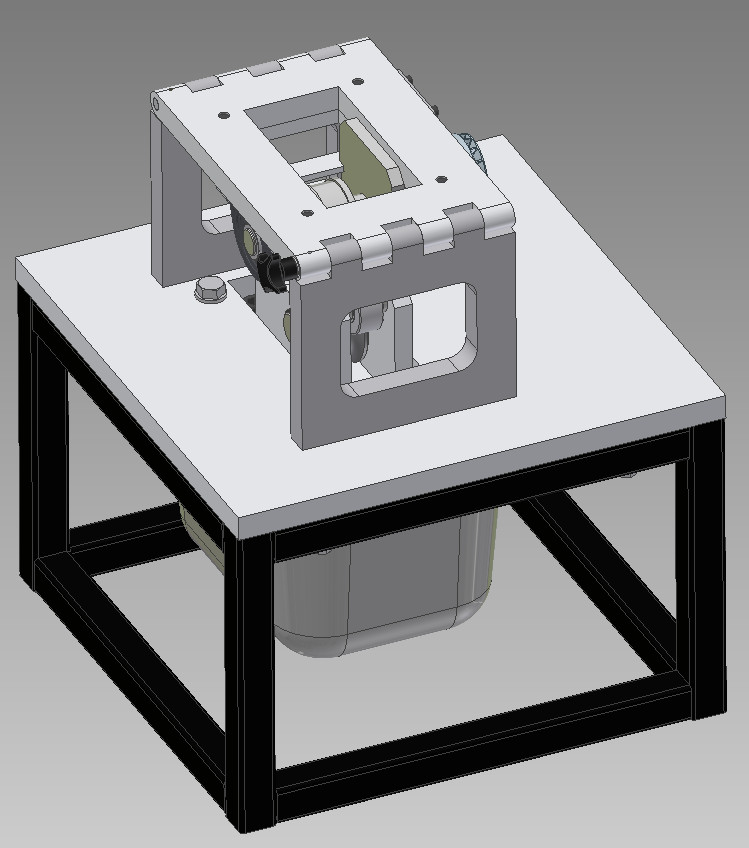

The RCF 8 is designed for evaluating rolling contact fatigue (RCF) performance under high-speed

and high-load conditions. It features a 12 mm rod specimen loaded against a 60 mm motordriven roller using two 20 mm diameter balls, which are supported and guided by profiled rollers.

A pneumatic actuator applies up to 4 kN of load, generating contact pressures up to 6 GPa.

With a 5:1 drive-to-test roller ratio, the test roller can reach 30,000 rpm, enabling rapid fatigue

testing for high-throughput data collection. A compact servo motor ensures precise speed control,

while the touch-screen interface allows for easy operation with minimal training. Designed for

bench mounting, the rig is space-efficient and ideal for fatigue life assessments of bearing steels.Features

- Wide Speed Range: 100 – 30,000 rpm

- High Load Capacity: Up to 4 kN

- User-Friendly: Simple touch-screen operation

- Compact Design: Bench-top mounted for space efficiency

- Cost-Effective: Reliable RCF testing at an affordable cost

The only measured parameter is vibration. Tests run for a set duration, cycle count, or

until specimen failure, detected by a vibration sensor on the test assembly.

Order As

RCF 8

-

Technical Specifications

Test Geometry: Two ball on rod Size of Text Balls: 20 mm diameter Rod Specimen: 12 mm diameter Driving Roller: 60 mm diameter Load Range: 100 – 4000 N Loading Method: Pneumatic Load Control: Precision pressure regulator Rotational Speed: 100 – 30,000 rpm Temperature: Ambient Motor: 0.5 kW servo motor Control: Touch-screen user interface Controlled Parameters

Rotational Speed Load Test Duration/Cycles Measured Parameters

Rotational Speed Load Test Duration/Cyles Vibration Levels Services

Electricity: 220/240V, single phase, 50 Hz, 1 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -