-

Description

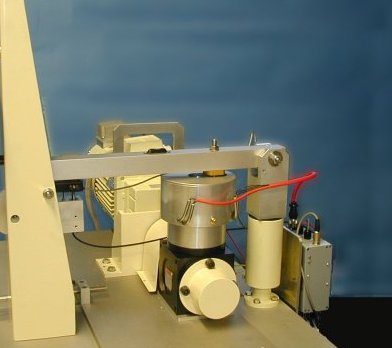

TE 88P Three Station Pin on Disc Machine is designed for wear testing of materials under high contact pressures in pin on disc configuration, in accordance with ASTM G99.

The machine is bench-mounted and includes a 2.2 kW variable speed a.c. vector motor and three pin on disc test stations.

A heated non-rotating fluid enclosure is provided with each test station allowing tests to be performed in fluid environments with a temperature limit of 200°C. A lid is provided to minimise fluid splashing. A thermocouple is fitted to the lower part of the enclosure to monitor and control the temperature.

Each test station has a load/friction/wear assembly. A loading beam is pivoted at one end and a pneumatic bellows is used to apply a load at the other end. A force transducer mounted on the bellows allows the applied load to be measured. Load is adjusted by means of a manually set precision regulator.

The load beam pivot is trunnion mounted and restrained from movement, when in the horizontal position, by pads mounted on the load application bracket. A strain gauge force transducer mounts on the load beam and fits between these pads when the arm is horizontal thus allowing the friction signal to be sensed.

An LVDT is mounted in contact with the underside of the load beam. As the pin wears, the vertical movement of the load beam is detected by the transducer. Wear of up to 1.5 mm at the contact can be measured.Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Contact Configurations: Pin on Disc Ball on Disc Number of Stations: Three Disc Diameter: 75 mm Track Radius: 0 to 35 mm Fluid Temperature: Ambient to 200°C Heating Power: 800 W Temperature sensor: k-type thermocouple Rotation Speed: 30 to 1,000 rpm Sliding Velocity: 0.12 to 4 m/s Normal Load: 10 to 1,000N Signal Conditioning: Strain Gauge Amplifier Module Friction Force Range: 500 N Signal Conditioning: Strain Gauge Amplifier Module Wear: LVDT Range: 1.5 mm Resolution: 1 µm Specimen Holder: 8 mm and 5.5 mm diameter pins 10 mm and 6 mm diameter balls Motor: 2.2 kW ac Software: COMPEND 2000 Automatically Controlled Parameters Rotational Speed x 1 Temperature x 3 Test Duration x 1 Manually Controlled Parameters Load x 3 Track Radius x 3 Measured Parameters Rotational Speed x 1 Friction x 3 Load x 3 Temperature x 3 Wear x 3 Number of Revolutions x 1 Test Duration x 1 Derived Parameters Sliding Speed x 3 Friction Coefficient x 3 Sliding Distance x 3 Services Electricity: 220/240V, single phase, 50 Hz, 3 kW 110/120 V, single phase, 60 Hz, 3 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Installation Bench-mounting machine: 1,300 x 720 x 850 mm high, 250 kg Bench-mounting cabinet: 530 x 530 x 350 mm high, 40 kg Packing Specifications: 1.25 m3, GW 271 kg, NW 193 kg -

Applications

-

Publications

Paper # 376 The Effects of Additive Elements on the Sliding Wear Behaviour of Fe-base Hardfacing Alloys Lee K Y, Lee S H, Kim Y, Hong H S, Oh Y M, Kim S J, Wear 255 (2003) 481 – 488 Paper # 572 Wear Behaviour of Plasma Sprayed WC-Ni Coatings C Tekmen, H Cetinel, A Turk, E Celik Key Engineering Materials Volume 264 – 268 (2004) p. 589 – 592 Paper # 630 Wear behaviour of thermal flame sprayed FeCr coatings on plain carbon steel substrate B Uyulgan, E Dokumaci, E Celik, I Kayatekin, NF Ak Azema, I Ozdemira, M Toparli, Journal of Materials Processing Technology Volume 190, Issues 1-3, 23 July 2007, p. 204-210 Paper # 682 Tribological behavior of Cr2O3 coatings as bearing materials Hakan Cetinel, Erdal Celik and Murat I Kusoglu Journal of Materials Processing Technology, Volume 196, Issues 1-3, 21 January 2008, p. 259-265 Paper # 745 Assessing the Tribocorrosion Performance of Three Different Nickel-Based Superalloys KC Tekin Tribology Letters 2010 Volume 37, Number 3, 563-572 Paper # 776 Optimization of reinforcement content and sliding distance for AlSi7Mg/SiCp composites using response surface methodology M Bayhan Materials & Design 2010 Volume 31, Issue 6, p. 3015-3022 Paper # 839 Evaluation of Die-Soldering and Erosion Resistance of High Velocity Oxy-Fuel Sprayed MoB-Based Cermet Coatings FF Khan, G Bae, K Kang, H Na, J Kim Journal of Thermal Spray Technology Volume 20, Number 5, 1022-1034 Paper # 887 Tribological properties of plasma electrolytic oxide coatings on magnesium alloys KC Tekin, U Malayoglu Tribology – Materials, Surfaces & Interfaces, Volume 6, Number 2, June 2012 , pp. 67-74(8) Paper # 1060 Tribology Testing of Lubrication and Surface Treatment of Tool Interfaces in Hot Forging of Aluminium CE Eggen Norges teknisk-naturvitenskapelige universitet ; Trondheim, June 2016 Paper # 1144 The Role of Oxide Tribofilms on Friction and Wear of Different Thermally Sprayed WC-CoCr JAR Wesmann, S Kuroda, N Espallargas Journal of Thermal Spray Technology – February 2017, Volume 26, Issue 3, pp 492–502 Paper # 1182 Effect of Contamination on the Friction and Wear of Carboxylic Acids in Aqueous Lubricants S Bernat, S Armada, N Espallargas Tribology Letters December 2018, 66:158 Paper # 1192 Friction Mechanisms by Carboxylic Acids in Aqueous Lubricants S Bernat, S Armada, N Espallargas Tribology Letters September 2018, 66:8 Paper # 1233 Tribological Behavior of Polymer Seal Materials in Water-Based Hydraulic Fluids S Bernat, A Brink, M Lucas J. Tribol 140(6), (May 21, 2018) Paper # 1342 Formulation and Testing of New Environmentally Acceptable Lubricants (EAL) for Use in Maritime Gear Components MG Aspnes 2019 – ntnuopen.ntnu.no -

User List

Launched 1997

EADS Germany Ostthuringishe Materialprufgesellschaft Germany Technical Universitaet Harburg, Hamburg Germany Chonbuk National University Korea Dong Ui University Korea Hang Yang University Korea Keimyung University Korea POSCO Kwangyang Korea SINTEF/NTNU Norway University of Cartagena Spain Kinetics Corporation Thailand Eylul University Turkey Smith & Nephew Ltd UK -

Download the Machine Leaflet