-

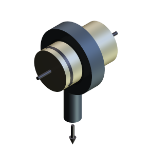

Description

The DN 222 test machine is a multi station bearing test rig for either plain or spherical journal bearings. Each test station is independently loaded by means of a servo hydraulic ram providing quasi static (low cycle) independently controlled loading of each bearing. Oscillating rotary motion is provided by a vector motor driven crank mechanism, which applies identical motion to each bearing under test. Displacement is adjusted manually by means of an adjustable crank.

The torque on each bearing test station is independently measured by means of in-line torque transducers and wear is measured by LVDTs.Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Contact Configurations: Area Contact Oscillating Motion: +/-30 degrees (continuous manual adjustment) Oscillating Frequency: 0.5 Hz (maximum) Motor Power: 5.5 kW Load per Station: 120 kN Interface: Phoenix Tribology USB micro-controller interface Software: COMPEND 2020 Controlled Parameters Speed Load Test Duration Measured Parameters Speed Load Specimen Temperature Friction Torque Wear Test Duration -

Applications

bearing friction journal bearing oscillating contact plain bearing materials plastics polymers -

User List

Launched 2002

Not disclosed

-

Download the Machine Leaflet