-

Description

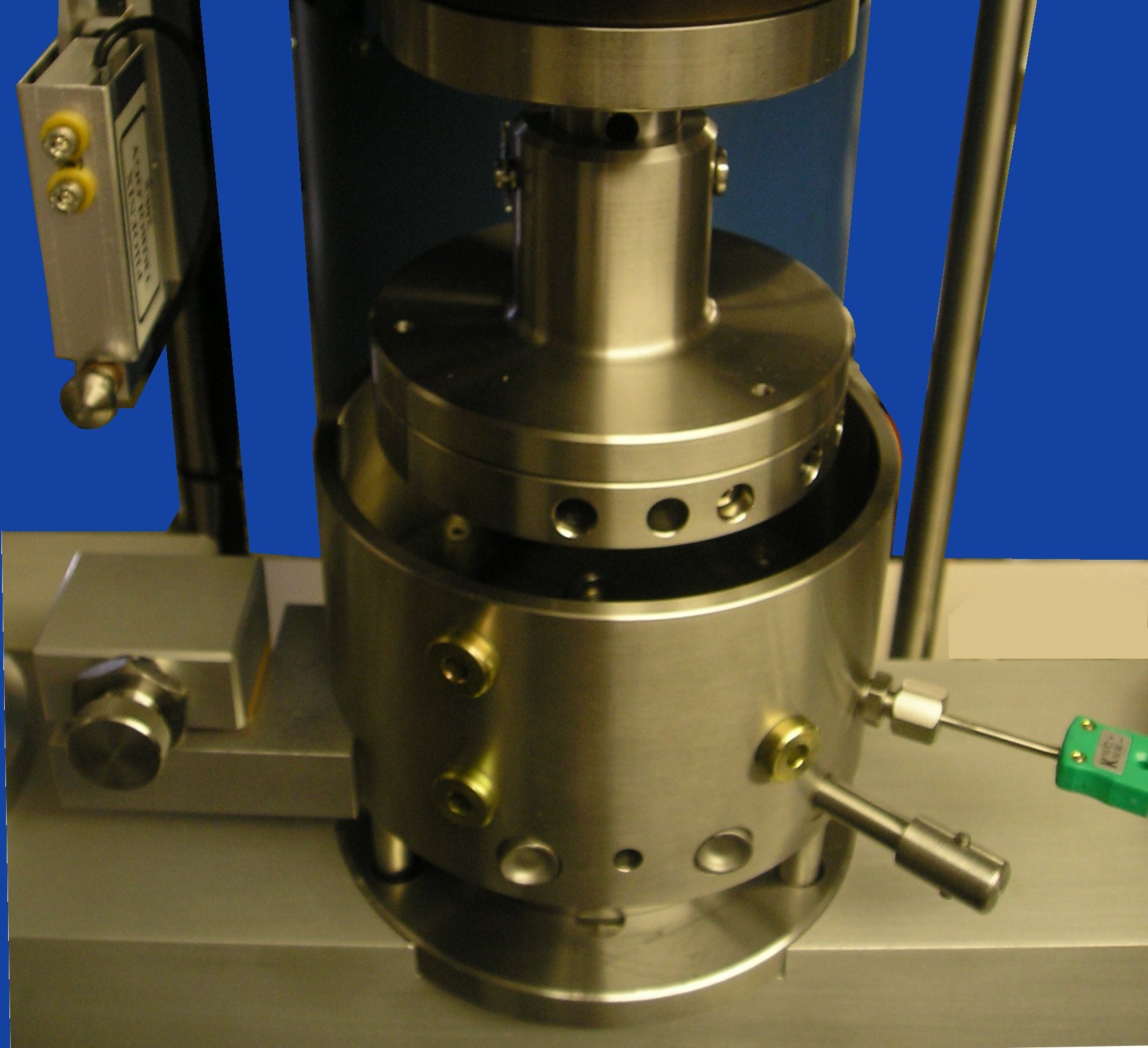

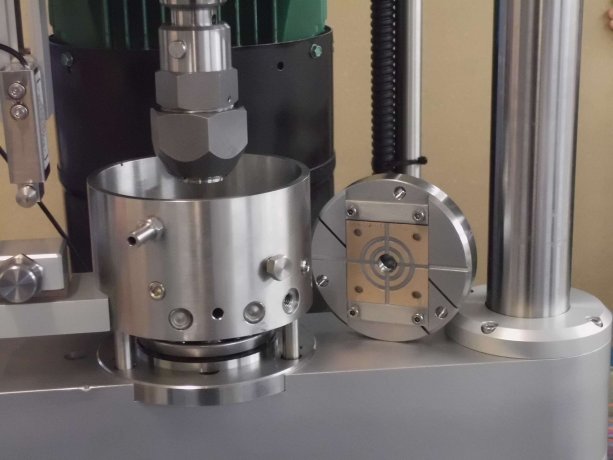

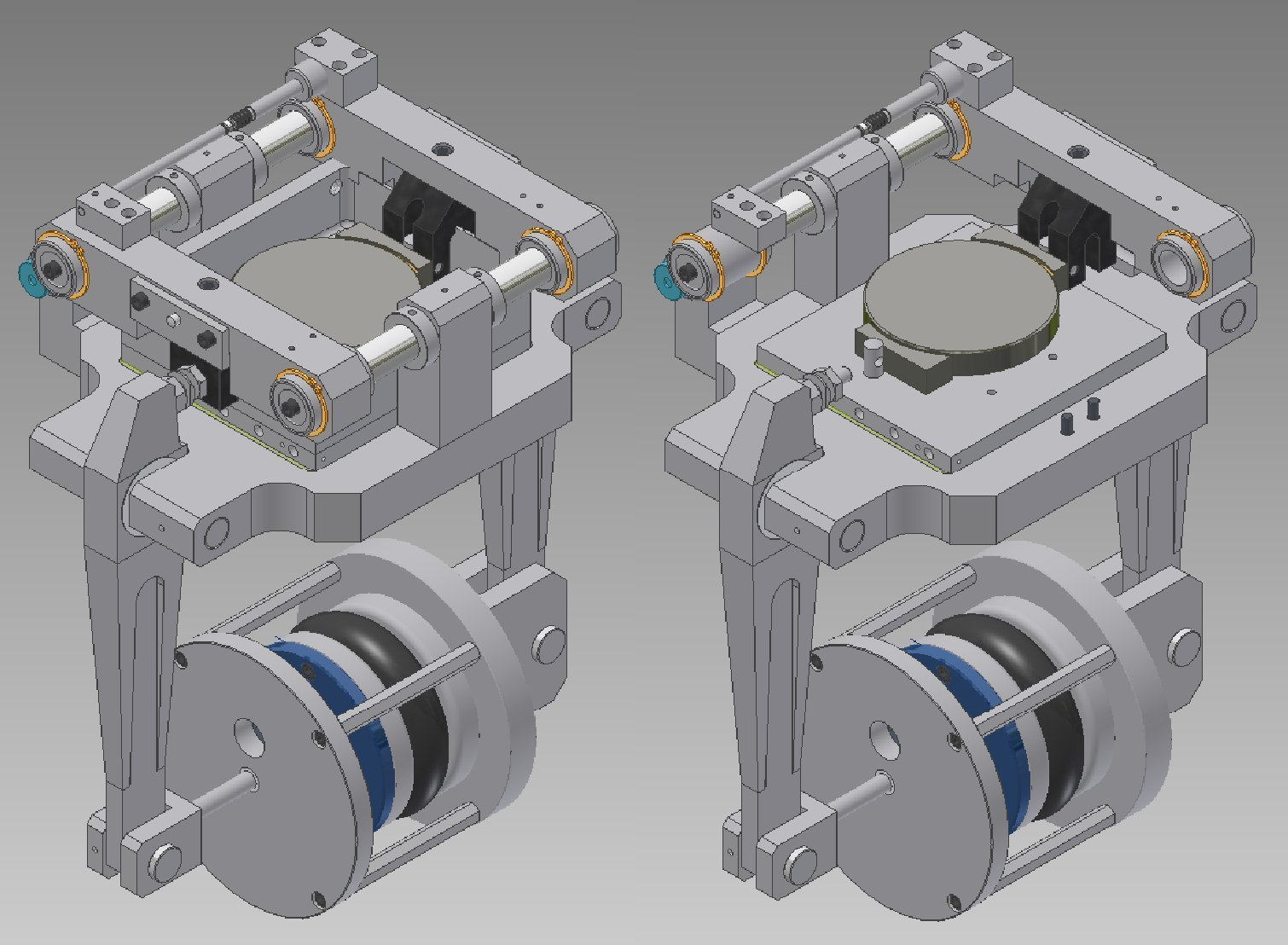

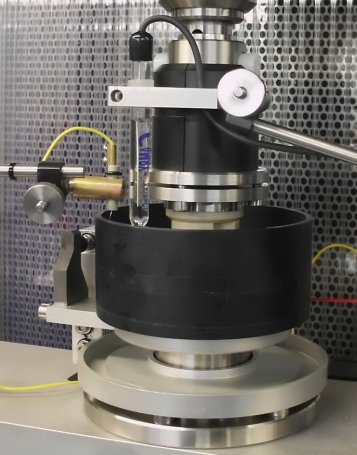

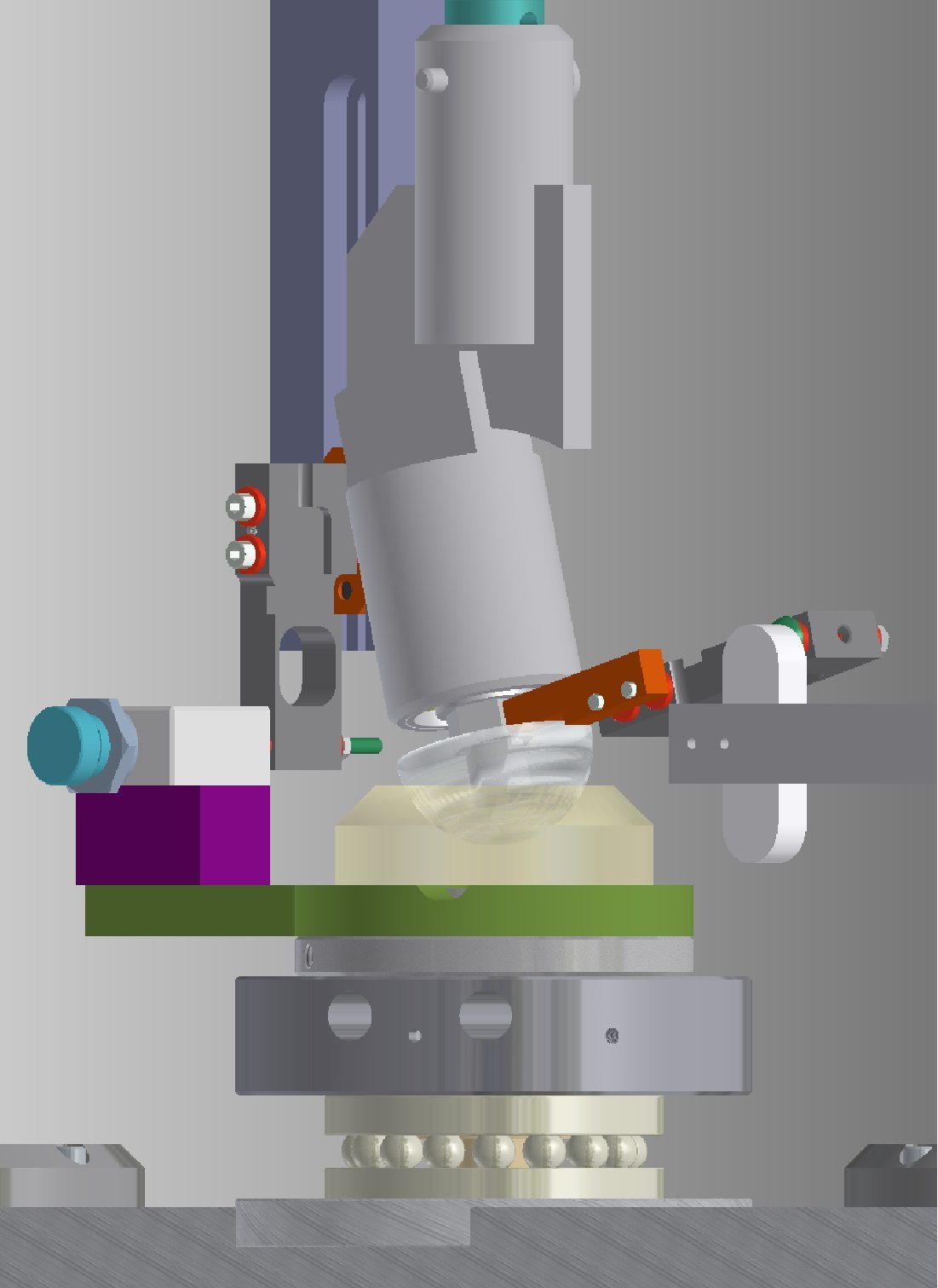

The TE 92 Rotary Tribometer is a versatile test machine for research and development work on materials and lubricants. With axial loading and an open test platform, the machine can accommodate multiple test geometries. Two versions of the machine are available.

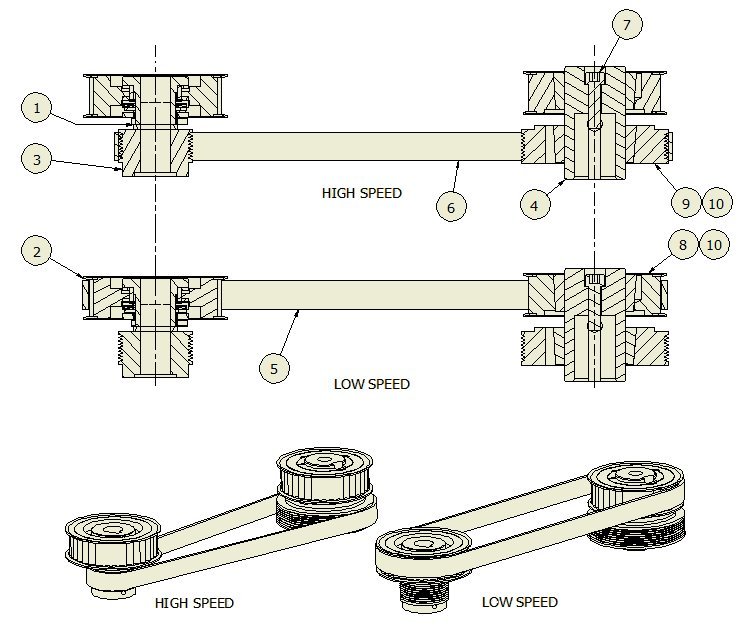

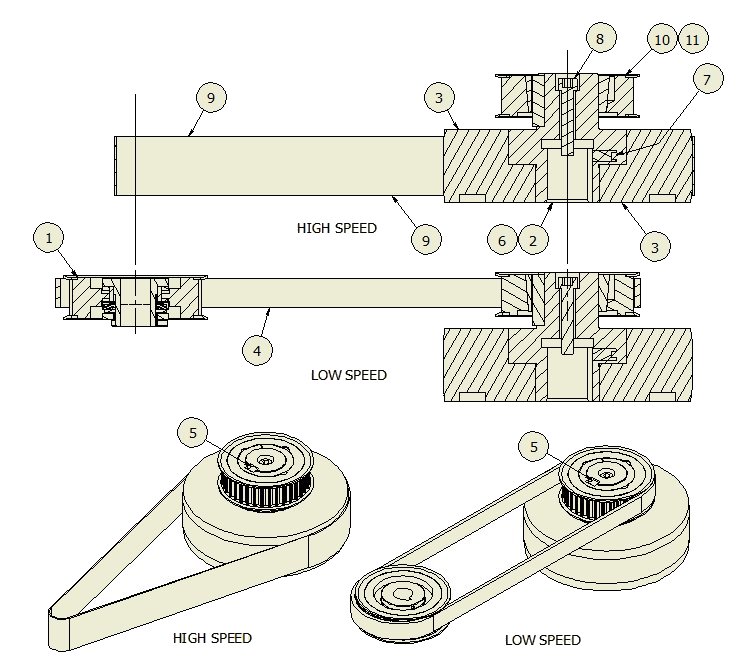

TE 92

A standard speed machine with 2.2 kW motor, single-phase supply and timing belt drive and torque limiter for speeds from 0 to 3,000 rpm and Poly-V belt drive for speeds 0 to 6,000 rpm. The test spindle main bearing is a taper roller bearing with maximum design speed of 6,000 rpm.

TE 92HS

A high speed machine with 2.2 kW motor and single-phase supply and timing belt drive and torque limiter for speeds from 0 to 3,000 rpm, high speed flat belt drive for speeds 0 to 10,000 rpm. The test spindle main bearings are a matched pair of super-precision angular contact bearings and the maximum design speed is 10,000 rpm.

Power Upgrade Option

Higher powered versions of both machines are available, with the 2.2 kW single-phase drive system replaced with a 4 kW three-phase system.

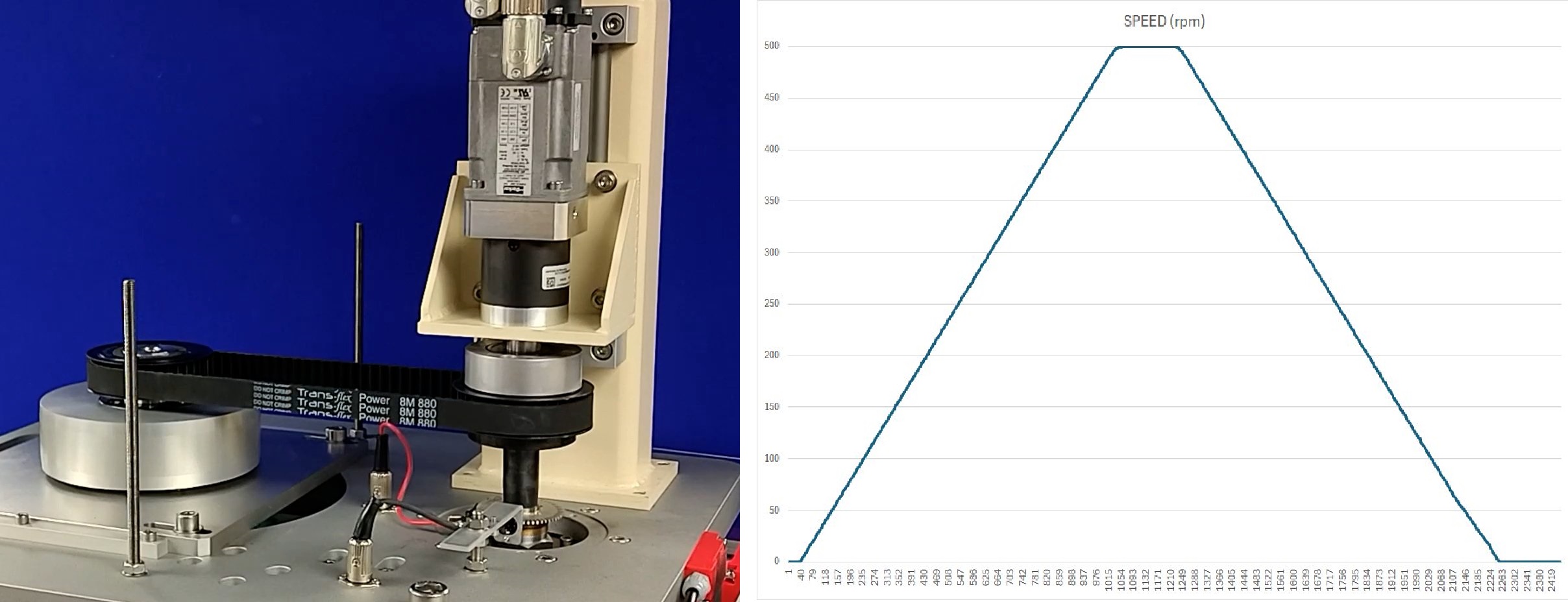

Low Speed Range Extension

At very low rotational speeds, most motors do not generate sufficient torque and speed control is poor; at very low speeds, “cogging” may occur. To improve very low speed control and smooth motion, while maintaining a high-speed capability, a geared servo motor can be mounted in parallel with the standard vector motor, connected to the test spindle via a sprag clutch. At speeds from 0 to 75 rpm, motion is controlled by the geared servo motor, with smooth transition to vector motor control, for speeds from 75 rpm to whatever the required maximum speed might be. Smooth speeds ramps, both speed increasing and decreasing, can be generated, with minimum controllable speed as low as 1 rpm.

Load and Torque Measurement

Test adapters are mounted on a cross beam with linear bearings mounted on the machine columns, loaded from underneath by a pneumatic bellows with an in-line force transducer for measurement and control of load. There are two interchangeable loading assemblies TE 92/1 and TE 92/2, providing a 500:1 turn-down ratio on load.

The test adapters are placed on a thrust bearing that permits free rotation under the influence of the frictional torque, which is resisted by a strain gauge force transducer.

Temperature Measurement

Thermocouples are located in the test adapters to measure the temperature of the test sample (either material or lubricant) and this measurement is used as the feedback for software PID temperature control.

Vibration Measurement

A piezo-electric sensor is provided to monitor vibration. The sensitivity of the detection circuit is adjustable by the operator. A sudden rise in vibration level, caused, for example, by pitting damage in a rolling contact fatigue test, will trip the circuit and stop the motor.

Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface. Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats.

Accessories and Adapters

TE 92/1 Low Load Actuator

The TE 92/1 provides a loading range of 20 to 1,000 N and this is used for pin on disc, thrust washer and 4-ball wear tests.

TE 92/2 High Load Actuator

The TE 92/2 provides a loading range of 200 to 10,000 N and this is used for taper bearing shear stability, 4-ball EP and rolling contact fatigue tests.

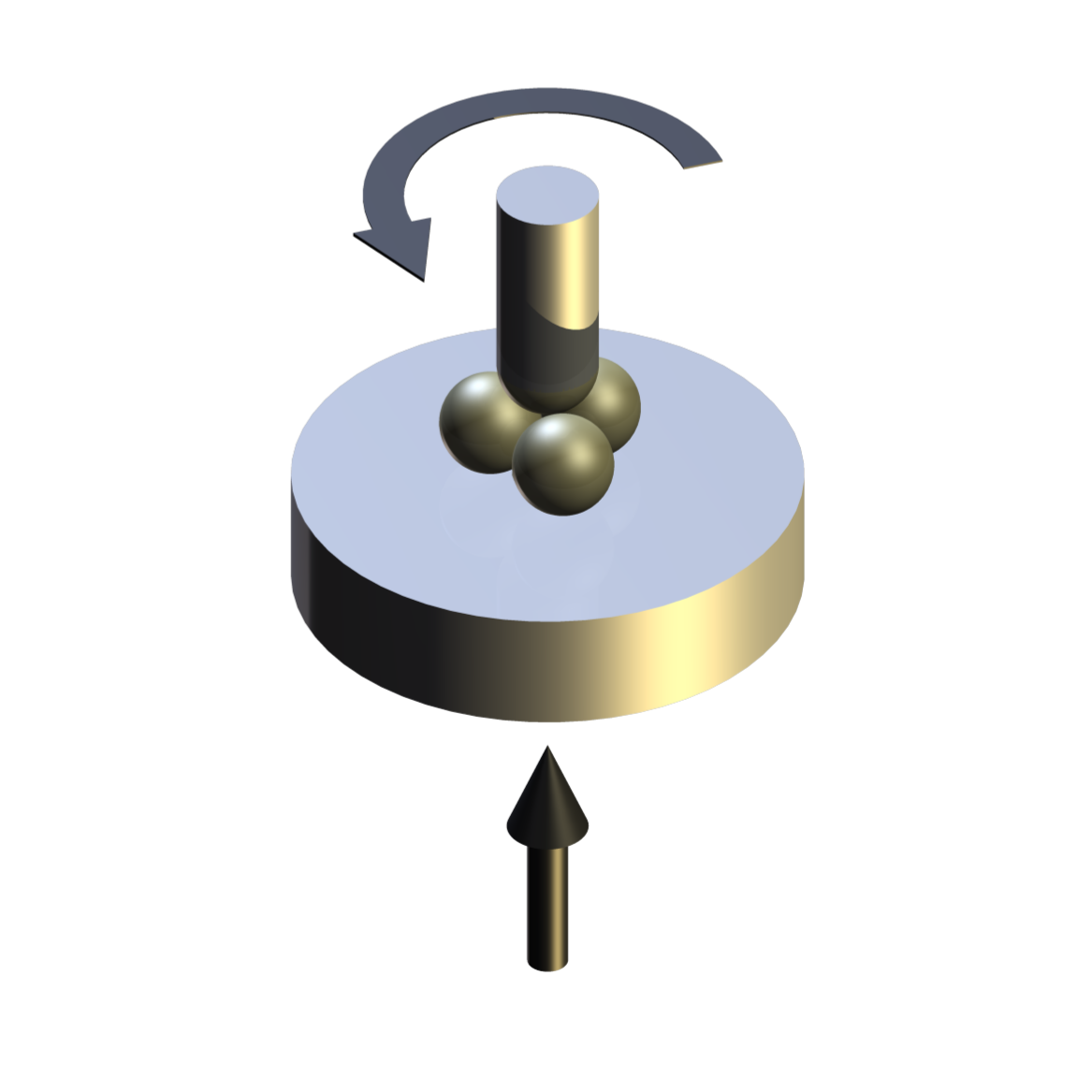

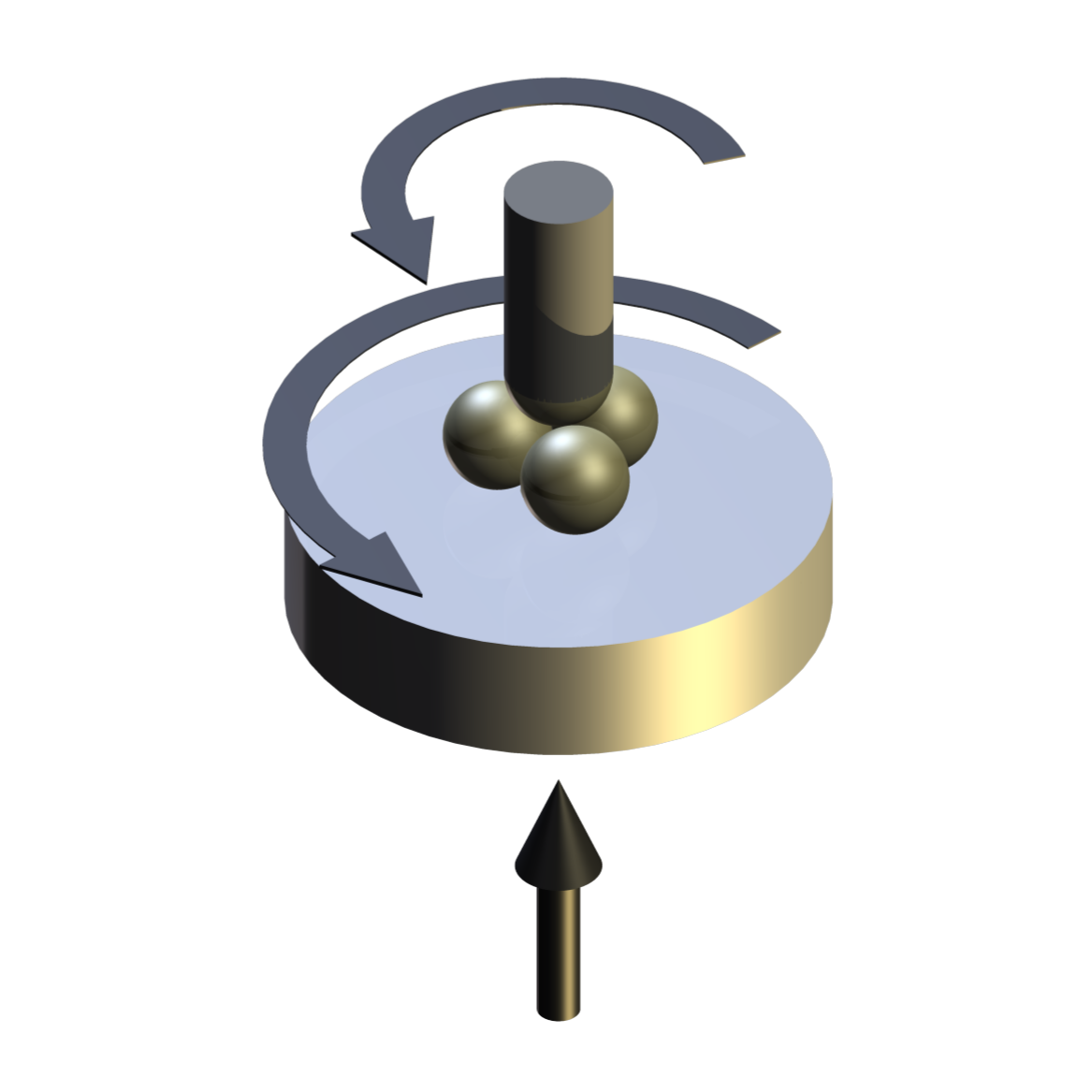

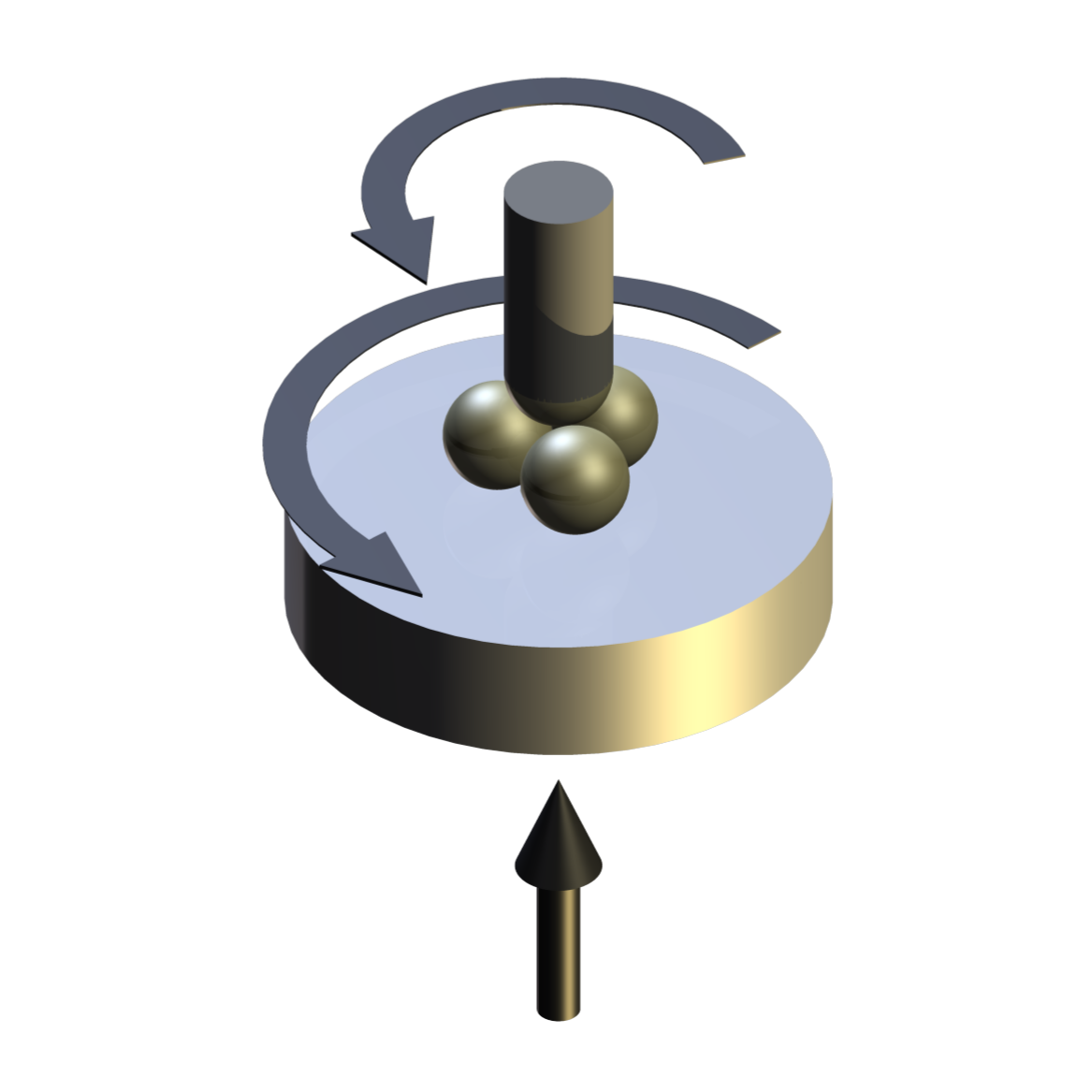

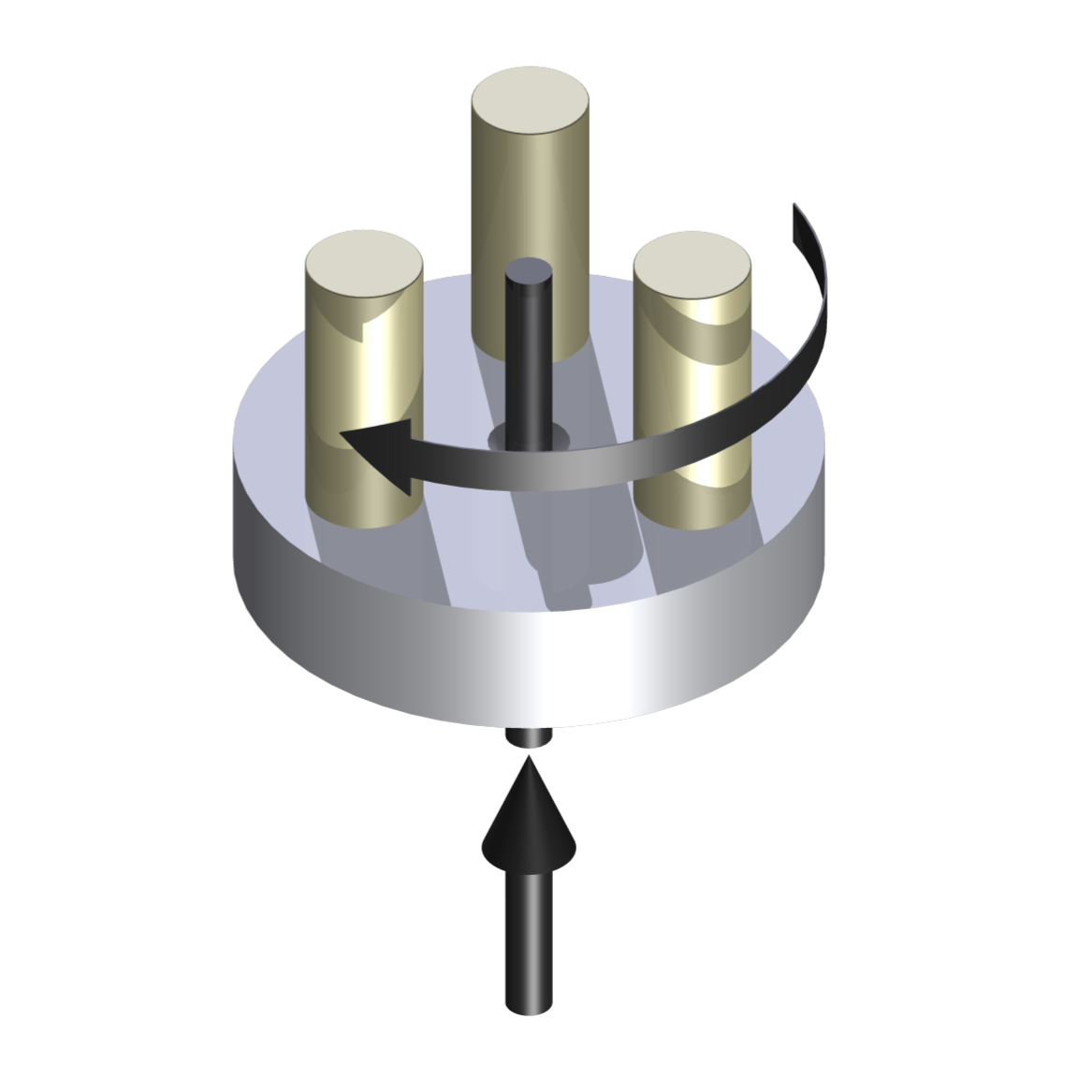

Four Ball Test Geometries

These adapters are used in conjunction with TE 92/FOUR Heater Pad and Ball Collet for Four Ball Tests. The split taper collet is a push fit into the spindle taper.

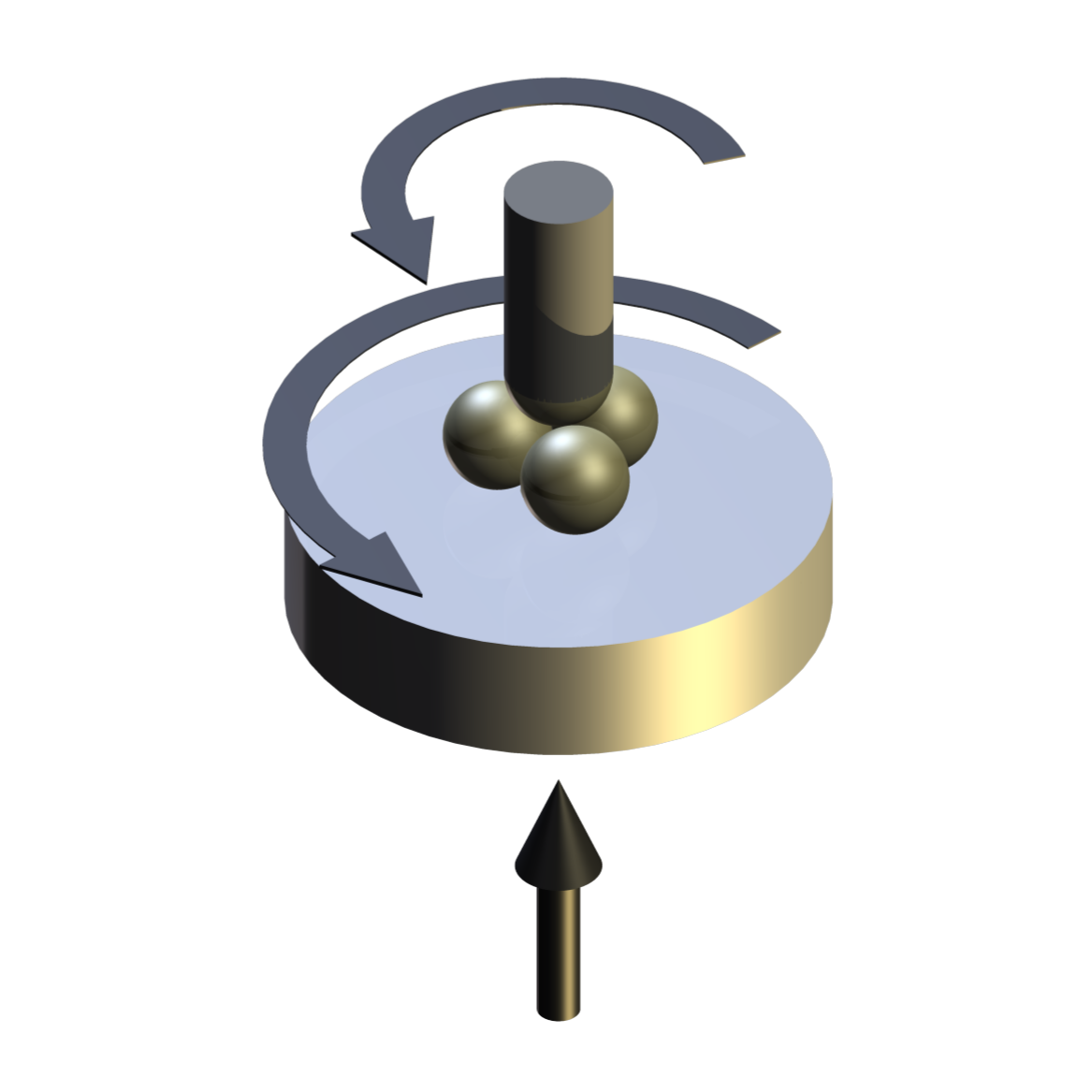

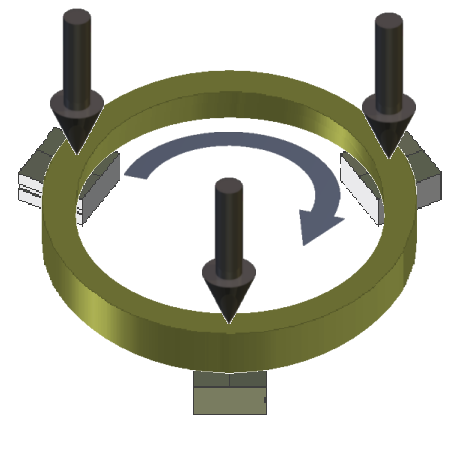

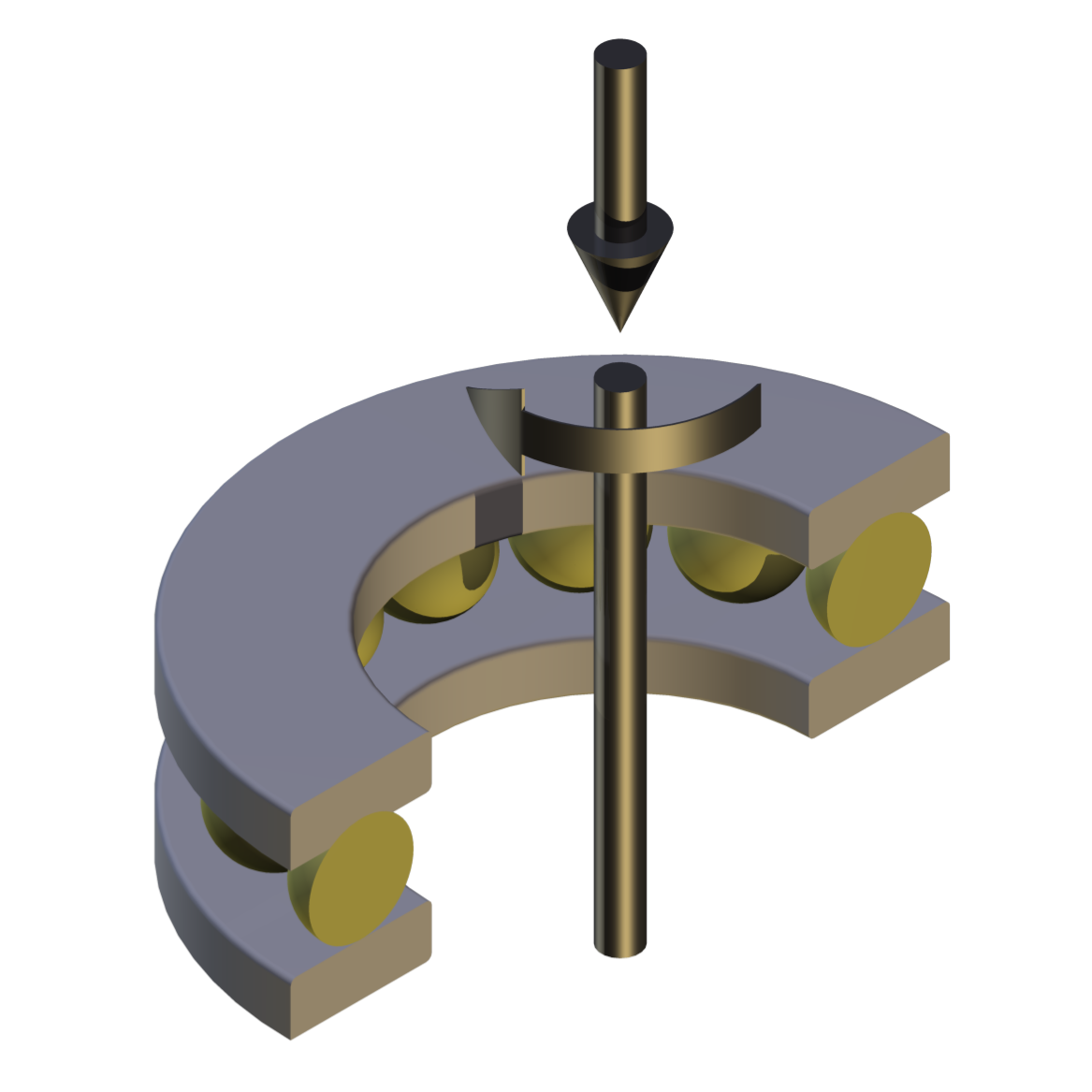

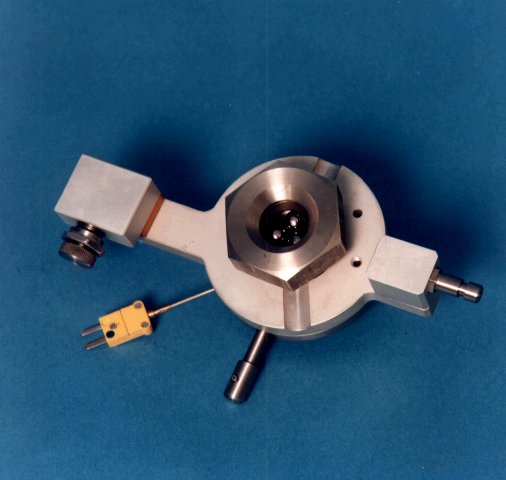

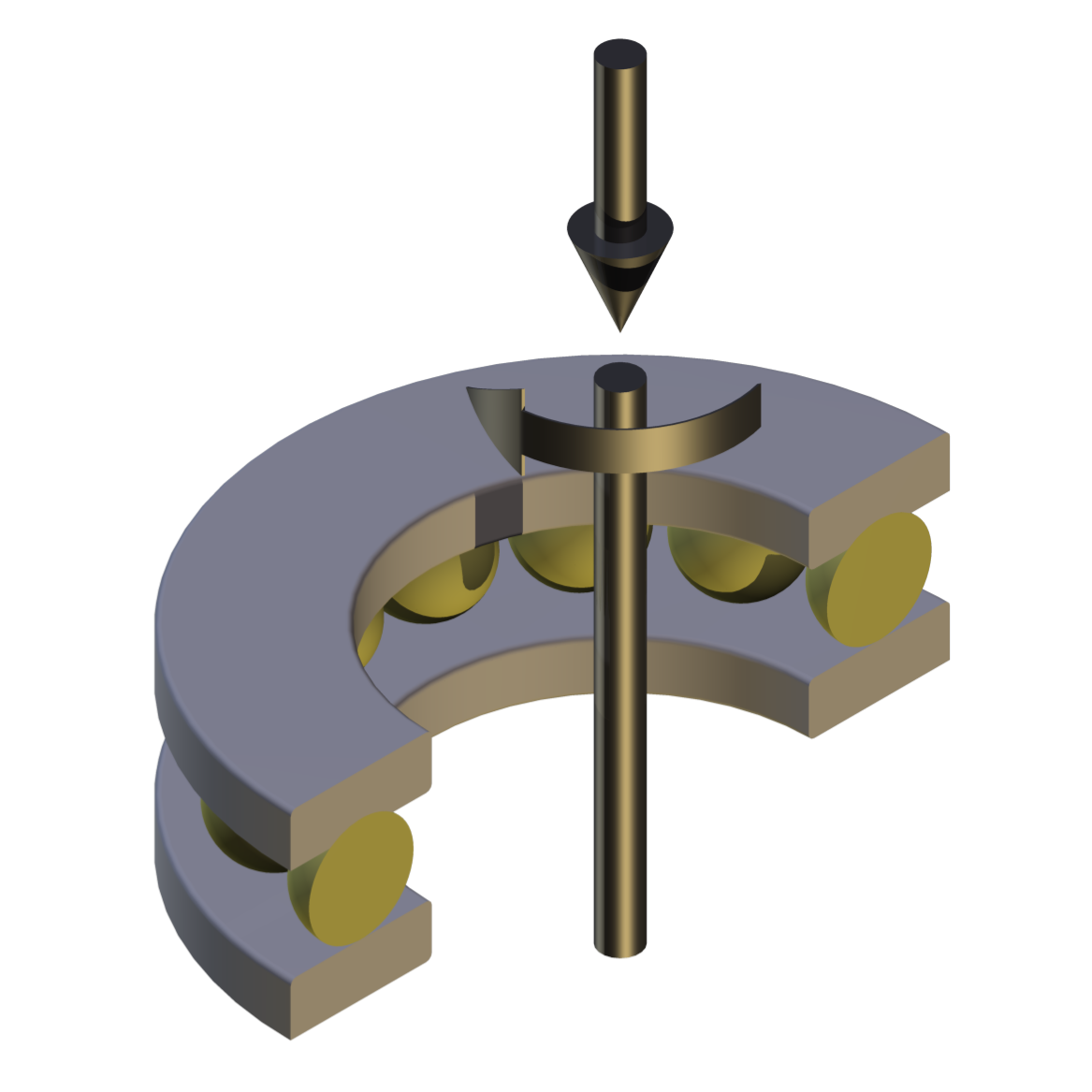

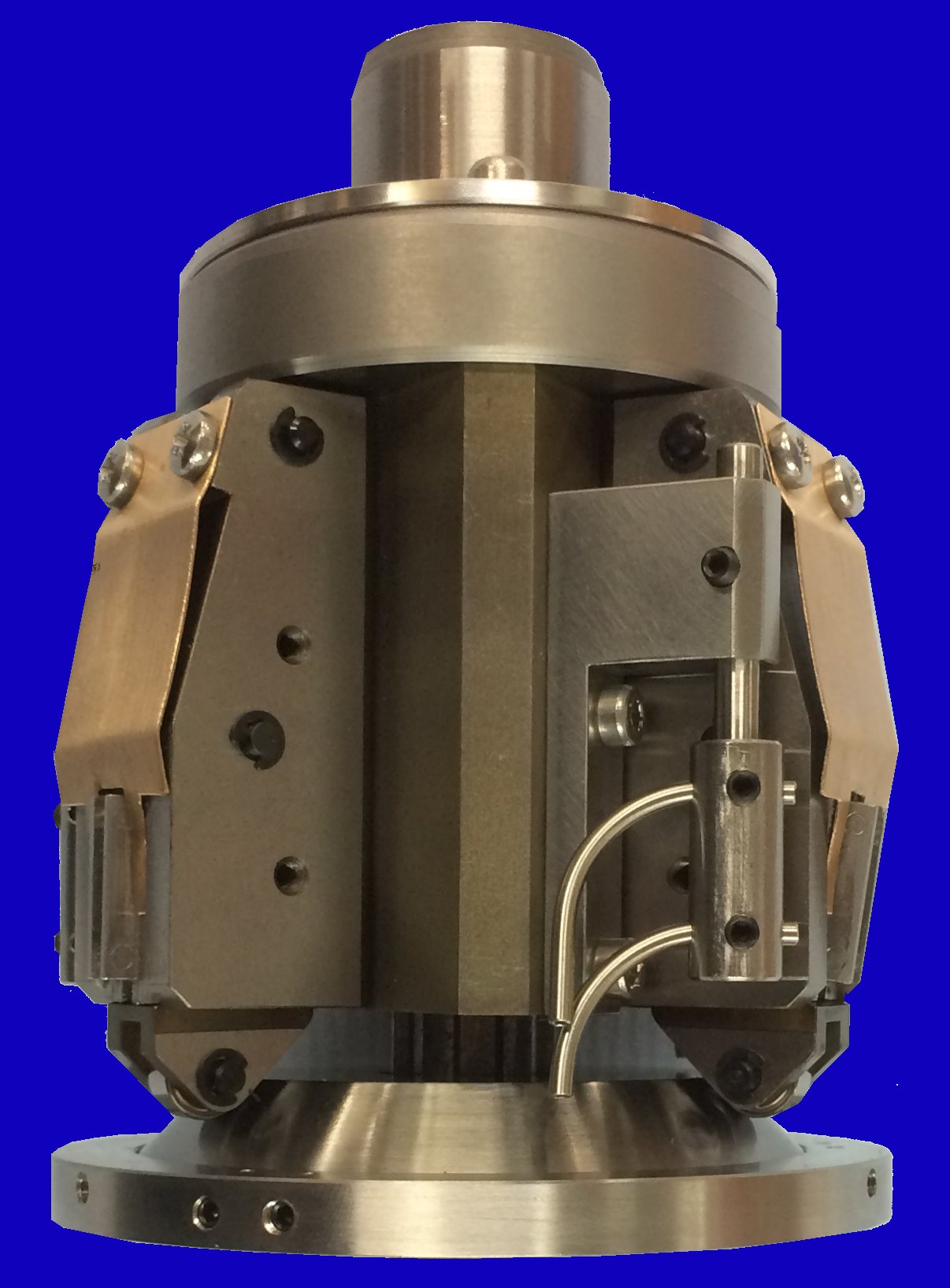

TE 92/FOUR/1 Sliding Four Ball Test Assembly

This adapter may be used in conjunction with TE 92/1 Low Load Actuator to perform tests in accordance with:

- • ASTM D2266 Wear Preventive Characteristics of Lubricating Greases

- • ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid

- • ASTM D5183 Determination of the Coefficient of Friction of Lubricants

And with TE 92/2 High Load Actuator to perform tests in accordance with:

- • ASTM D2596 Extreme Pressure Properties of Lubricating Greases

- • ASTM D2783 Extreme Pressure Properties of Lubricating Fluid

- • IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants

- • DIN 51350/1-5 Testing Lubricants: Testing in the Shell Four-Ball Tester

- • ISO/CD 11008 Petroleum Products and Lubricants – Determination of Extreme Pressure Properties of Lubricating Greases – Four Ball Method

The adapter is designed to locate on the TE 92/DM Digital Microscope with Camera & PC Image Capture Software. This enables image capture and measurement of the wear scar on the test balls, without having to remove the balls from the test adapter.

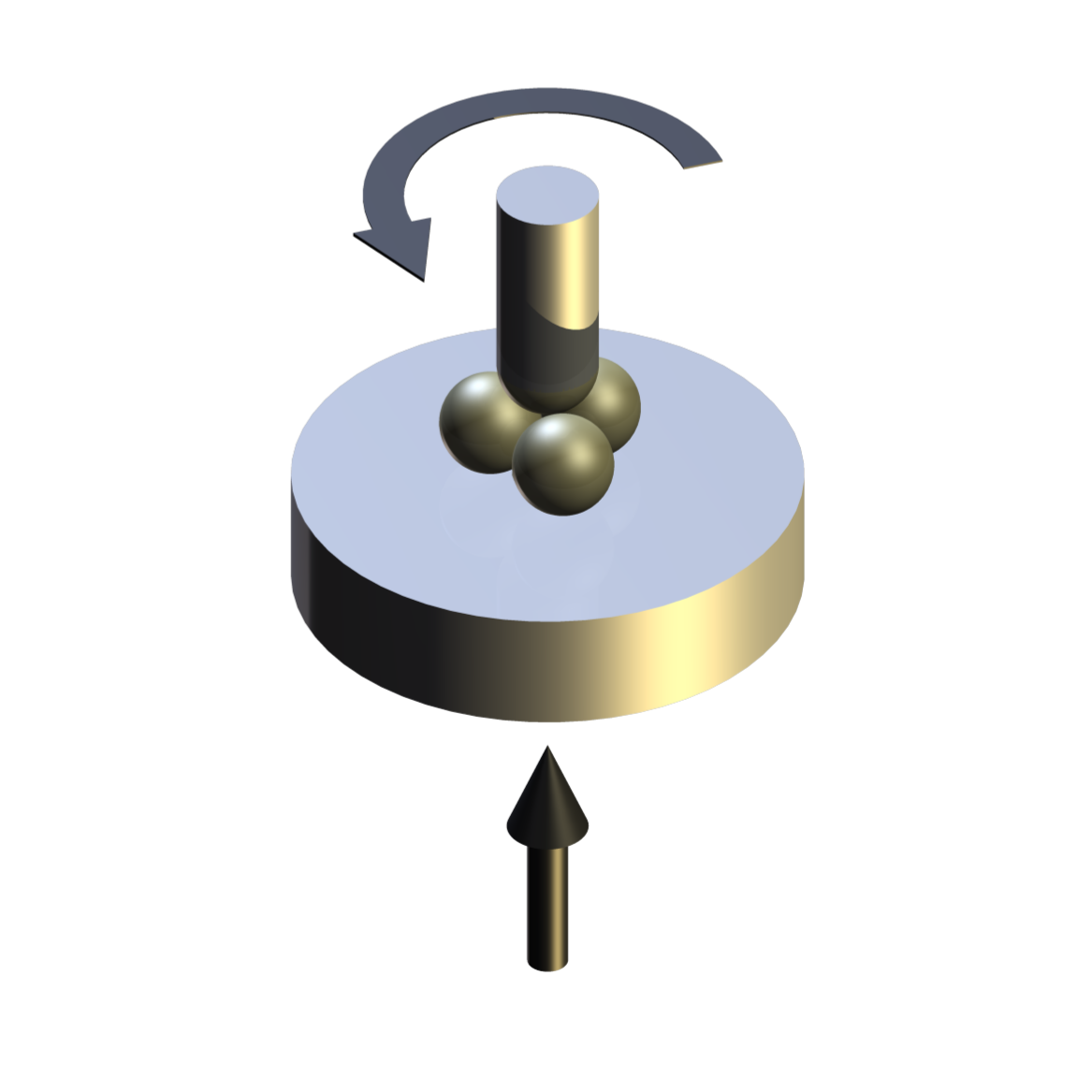

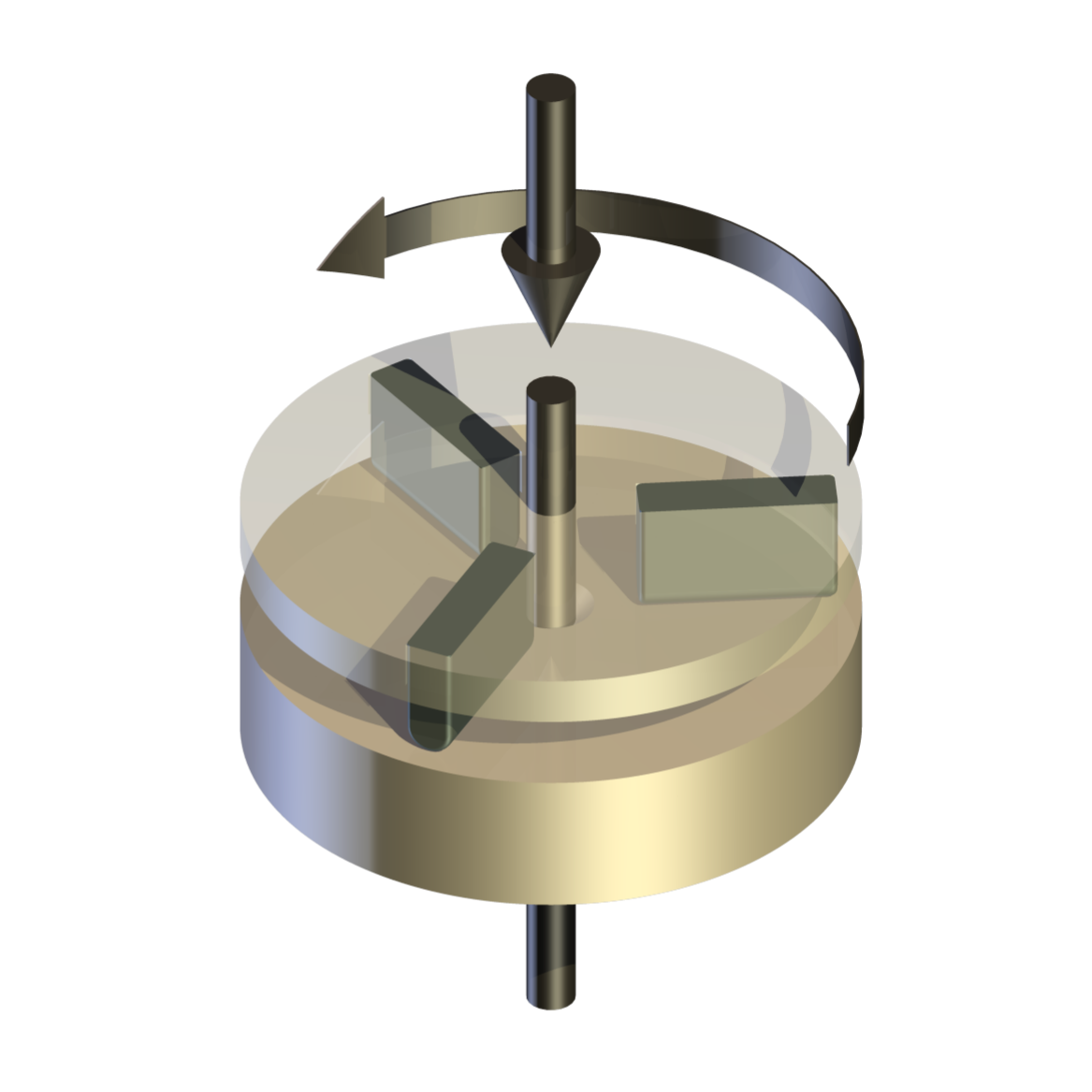

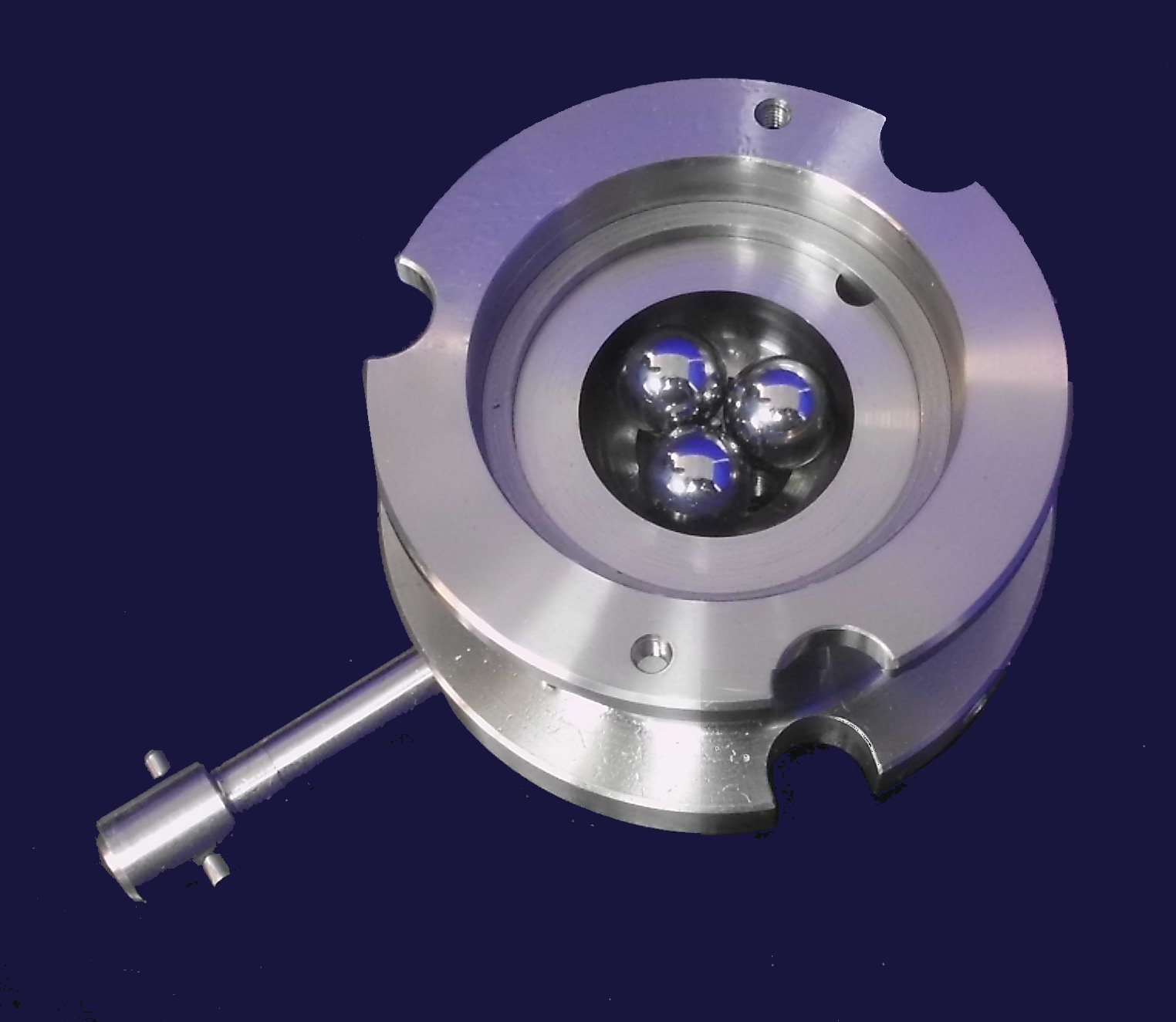

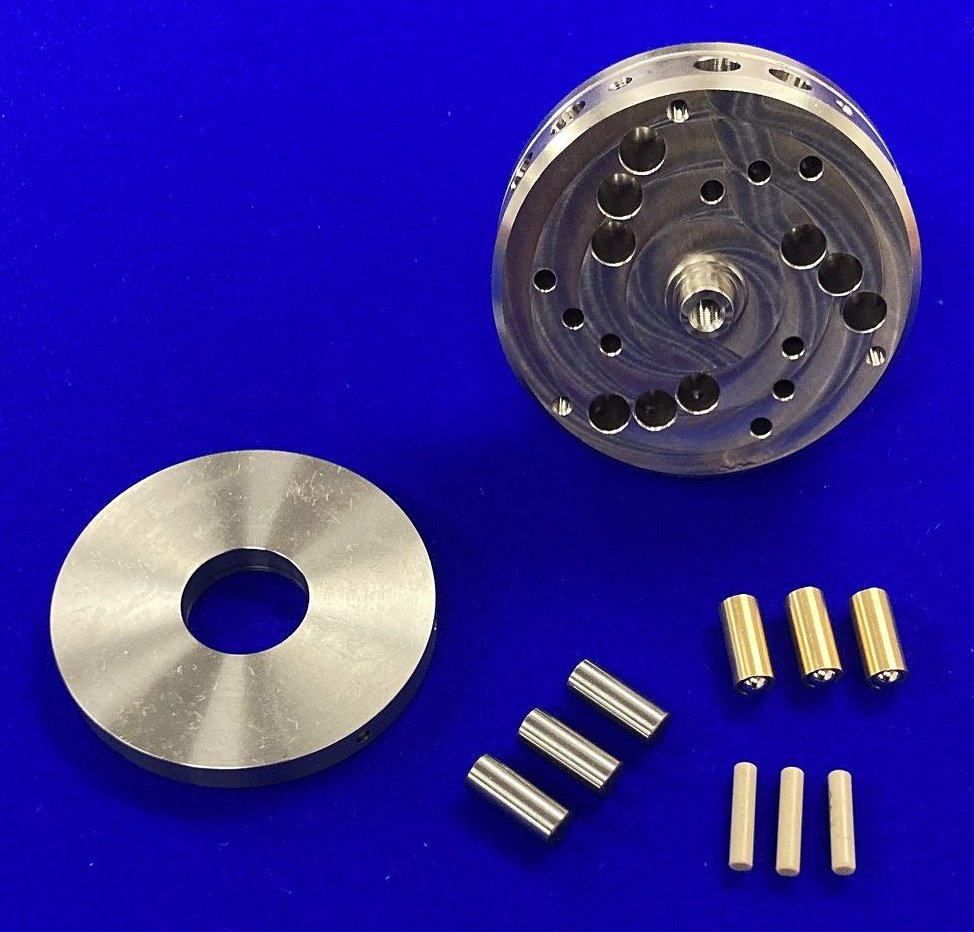

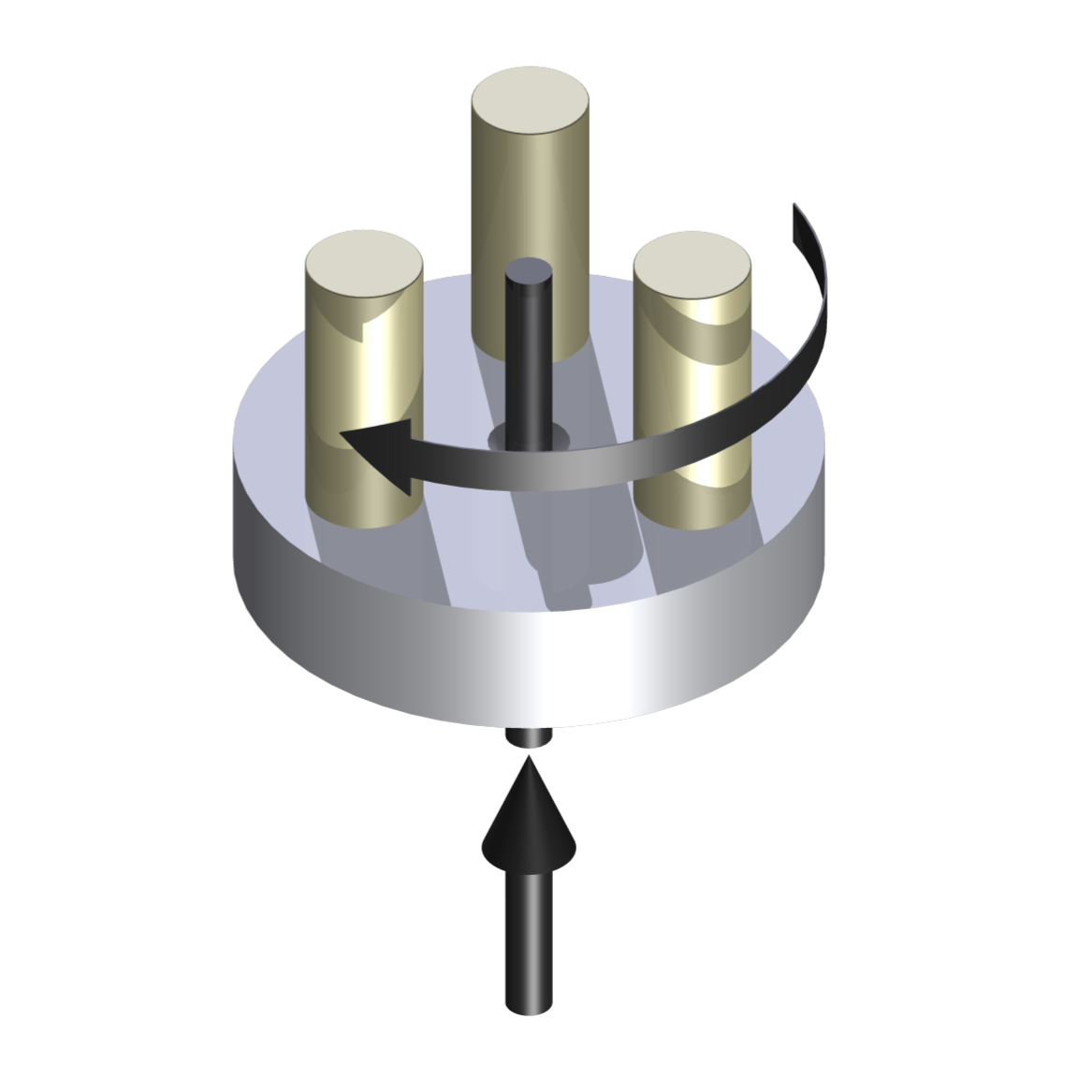

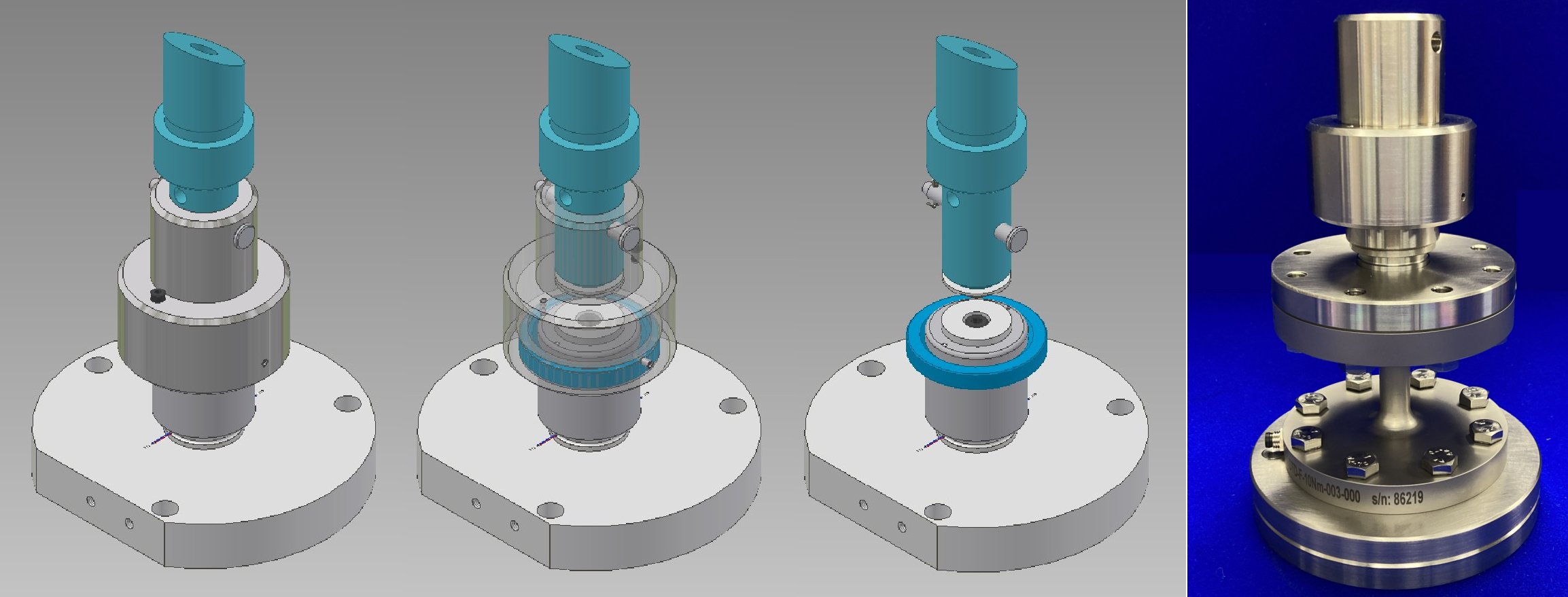

TE 92/FOUR/2 Rolling Four Ball Test Assembly

This comprises a test reservoir and precision polished test race. In this case there is no torque measurement. The adapter may be used in conjunction with TE 92/2 High Load Actuator to perform tests in accordance with:

- • IP 300 Rolling Contact Fatigue Tests for Fluids

TE 92/FOUR/INCH Rolling Four Ball Adapter (25.4 mm balls)

This adapter is for running rolling four ball tests with inch balls, separated by a cage.

AREA CONTACT TEST GEOMETRIES

These adapters and associated tooling inserts are normally used in conjunction with the self-aligning heated reservoir and are typically used in conjunction with TE 92/1 Low Load Actuator.

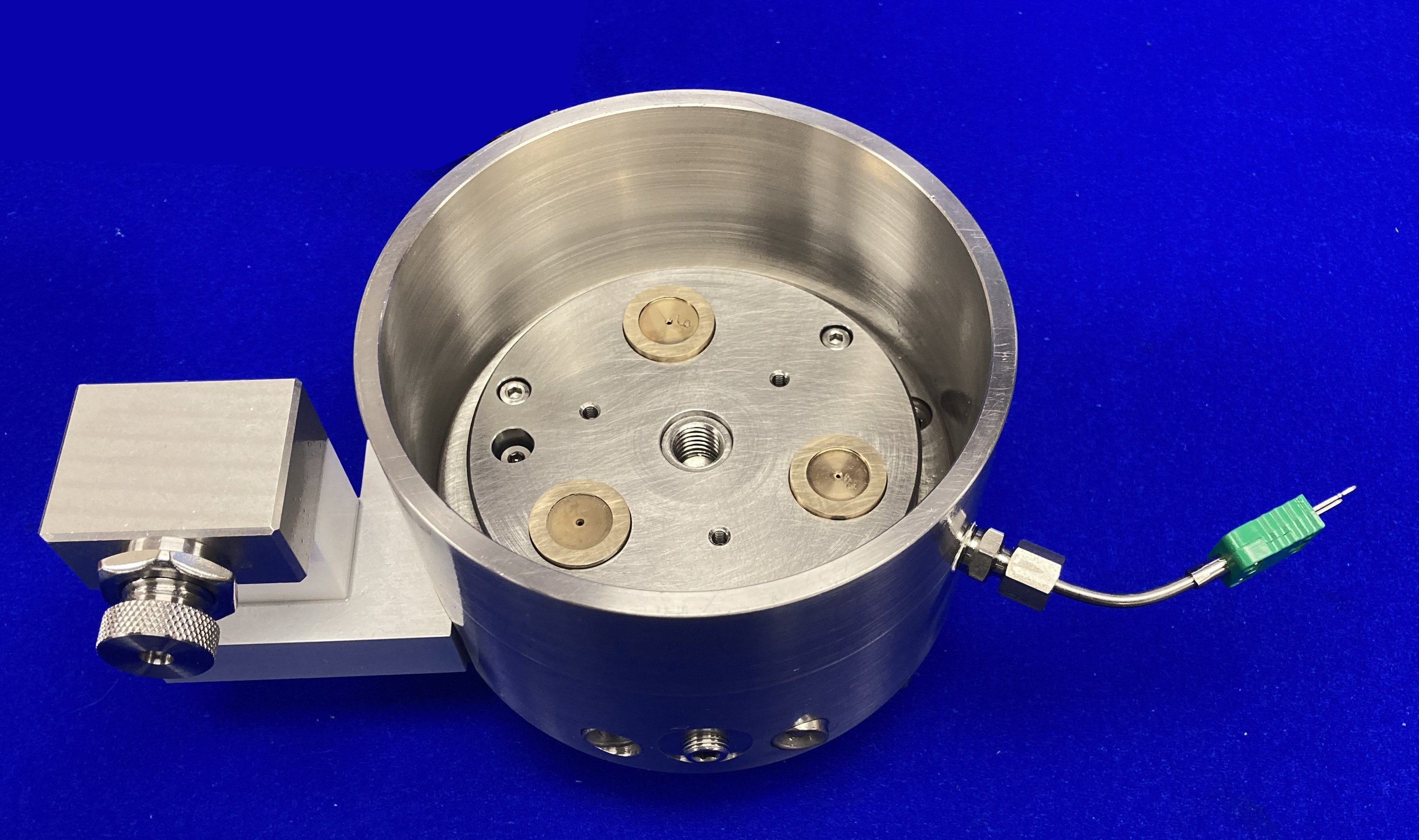

TE 92/AREA-L Heated Test Bath & Shaft Hub for Lubricated Tests

This is a test bath and shaft hub, for lubricated tests. It is used with any of the six current tooling inserts. The bath has a central port for lubricant feed and drain ports at different levels. It incorporates cartridge heaters and thermocouple for specimen heating and temperature measurement.

Test fluid may be fed by gravity or circulated through the enclosure using the TE 92/LS Lubricant Re-circulating System or other suitable circulation system. A lid is provided for the reservoir to minimise loss of fluid by splashing or evaporation.TE 92/AREA-D Specimen Mount with Capacitance Wear Sensor & Shaft Hub for Dry Tests

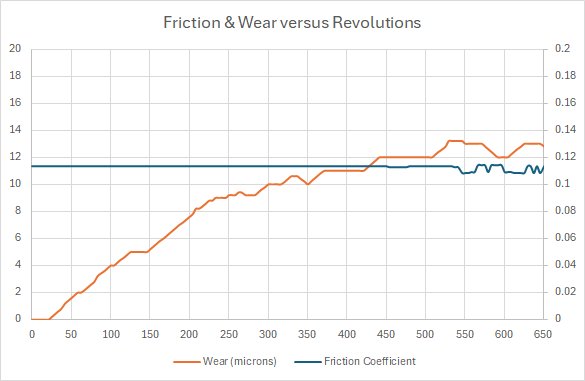

This is a heated specimen mount with capacitance wear sensor and shaft hub, for dry tests. On-line wear measurements can only sensibly be made with specimens and test conditions that generate a measurable amount of wear, typically of the order of microns or tens of microns. This limits the usefulness of capacitance wear measurement to dry sliding tests using materials such as polymers, using either three pin-on-disc or thrust washer tooling.

TE 92/AREA-H Specimen Mount & Shaft Hub for Dry Tests up to 600°C

This is a high temperature specimen mounting for dry tests using either three pin-on-disc or thrust washer tooling.

TE 92/AREA-C Heated & Cooled Test Bath & Shaft Hub for Non-circulating Lubricated Tests

This adapter is for immersed (non-circulating) lubricant tests. In addition to the standard heaters, the assembly incorporates cooling passages that can be connected to a laboratory chiller.

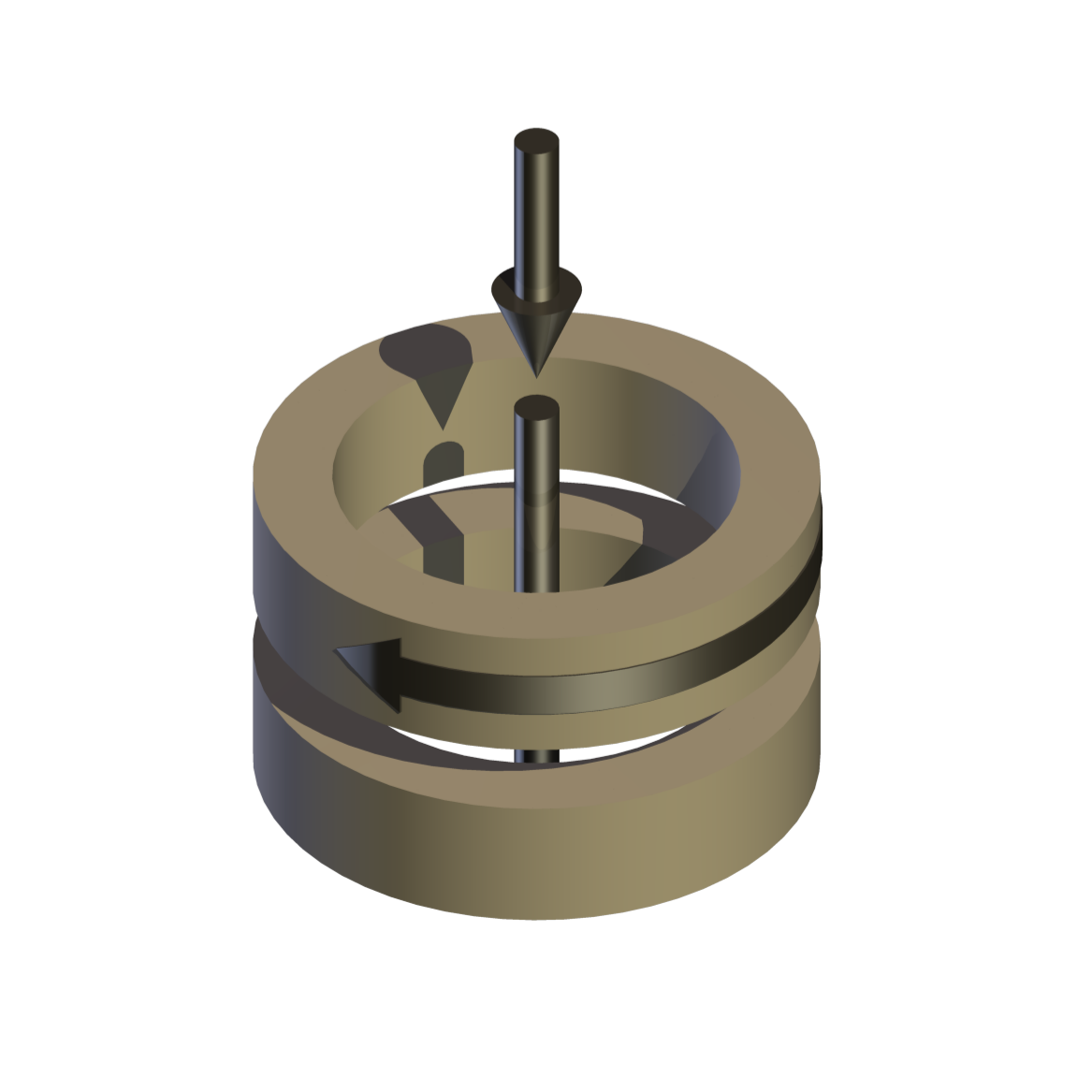

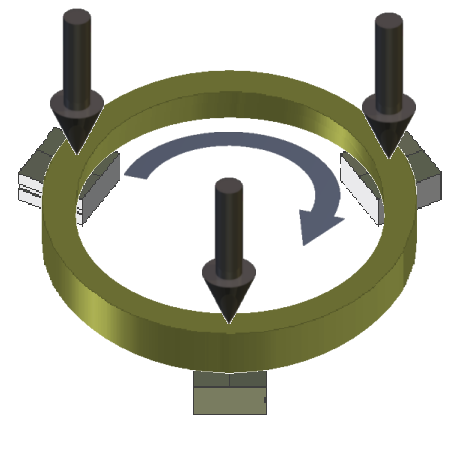

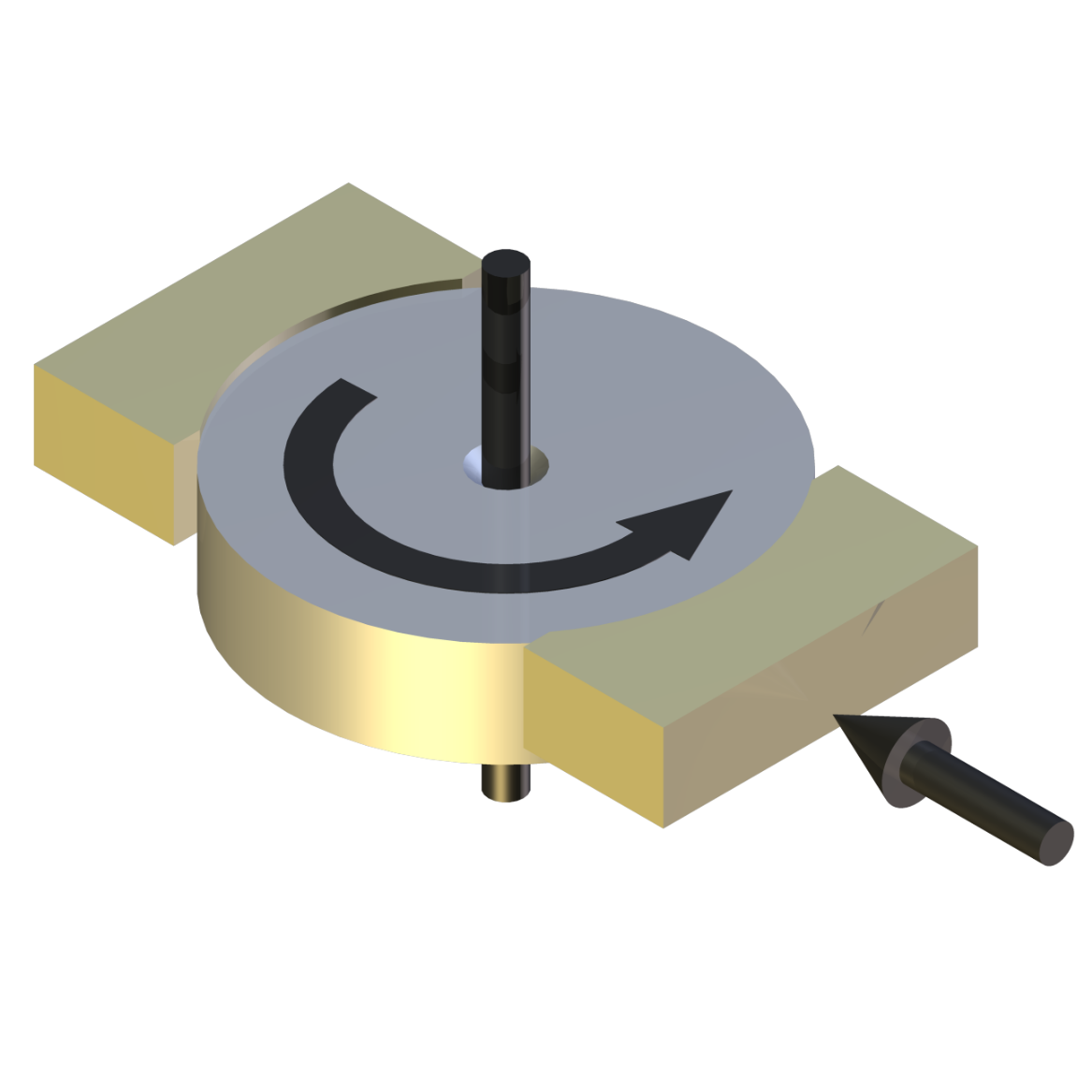

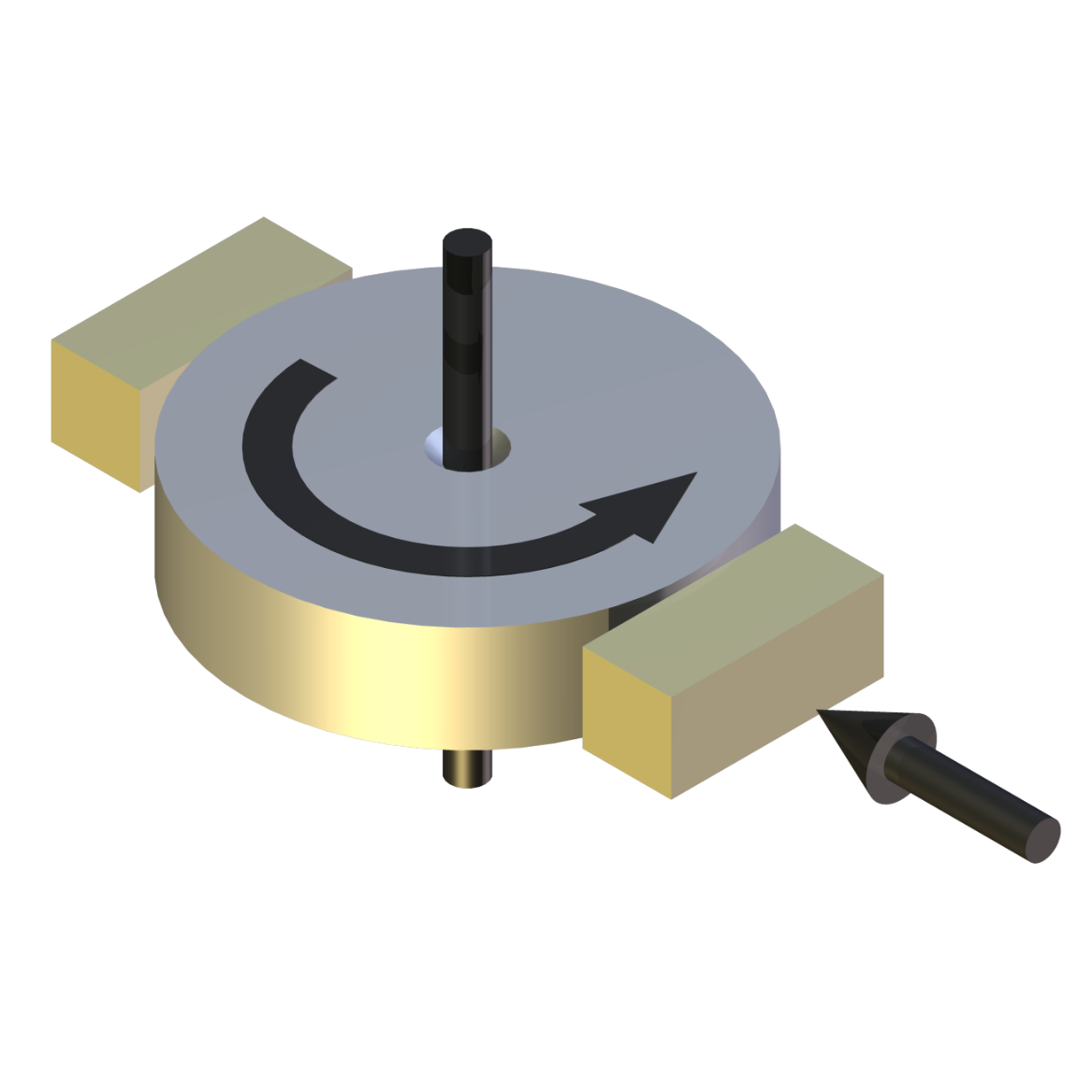

TE 92/AREA/1 Three Pin on Disc Tooling

The tooling is used in conjunction with either TE 92/AREA-L, TE 92/AREA-D or TE 92/AREA-H to perform tests generally in accordance with:

- • ASTM G99 Wear Testing with a Pin-on-Disc Apparatus

- • DIN 50324 Measuring Friction and Wear: Model Experiments on Sliding Friction in Solids

The test geometry is a rotating three pin carrier loaded against a non-rotating lower disc.

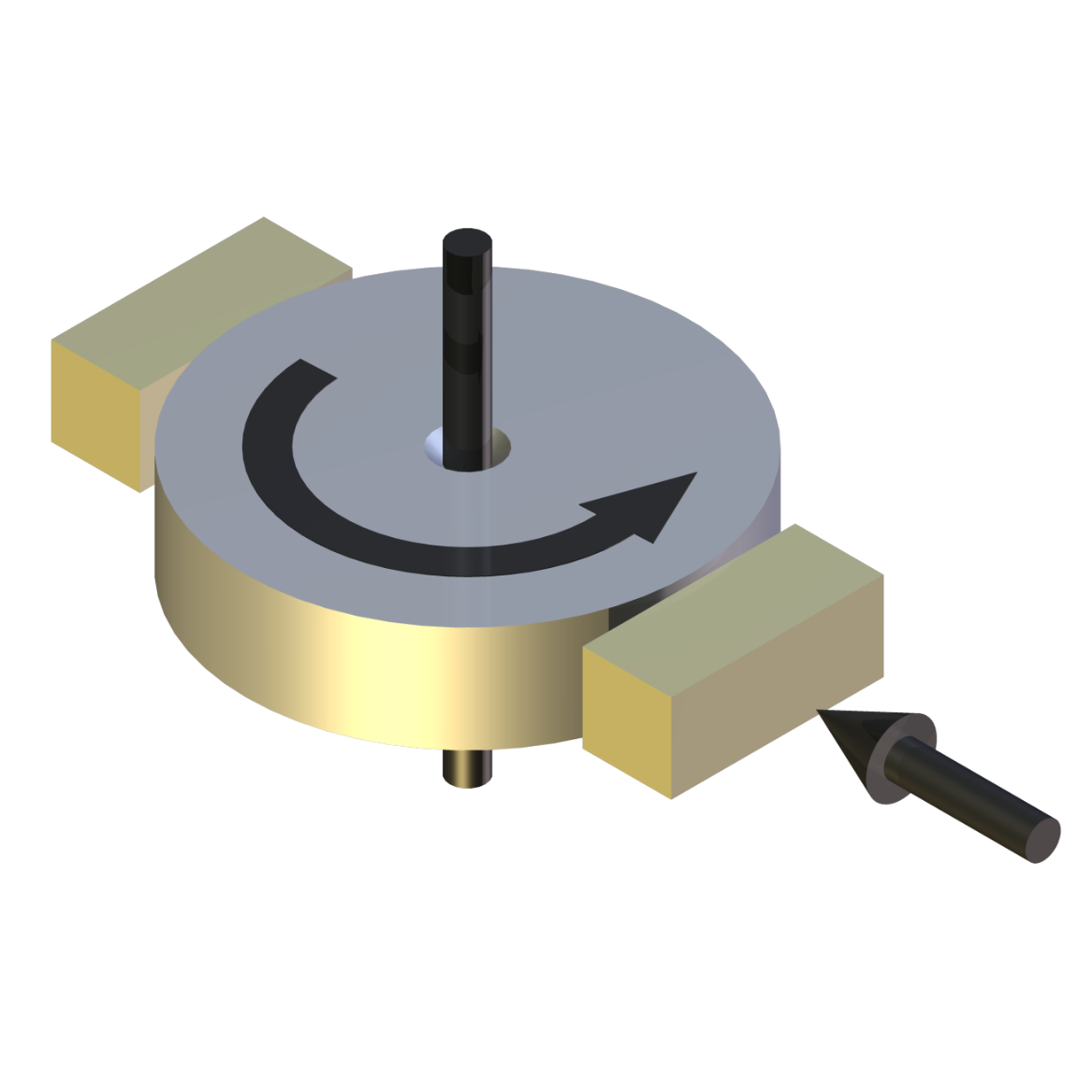

TE 92/AREA/2 ASTM D3702 Thrust Washer Specimen Tooling

The tooling is used in conjunction with either TE 92/AREA-L, TE 92/AREA-D or TE 92/AREA-H to perform tests generally in accordance with:

- • ASTM D3702 Standard Test Method for Wear Rate of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine

- • ISO/DIS 7148-2 Testing of the Tribological Behaviour of Bearing Materials

The tooling can easily be customised to accommodate non-standard sized specimens.

TE 92/AREA/3 LVFA (small) Specimen Tooling

The tooling is used in conjunction with TE 92/AREA-L to perform tests using small-scale LVFA friction material test samples. This tooling is normally customised to meet client specific requirements.

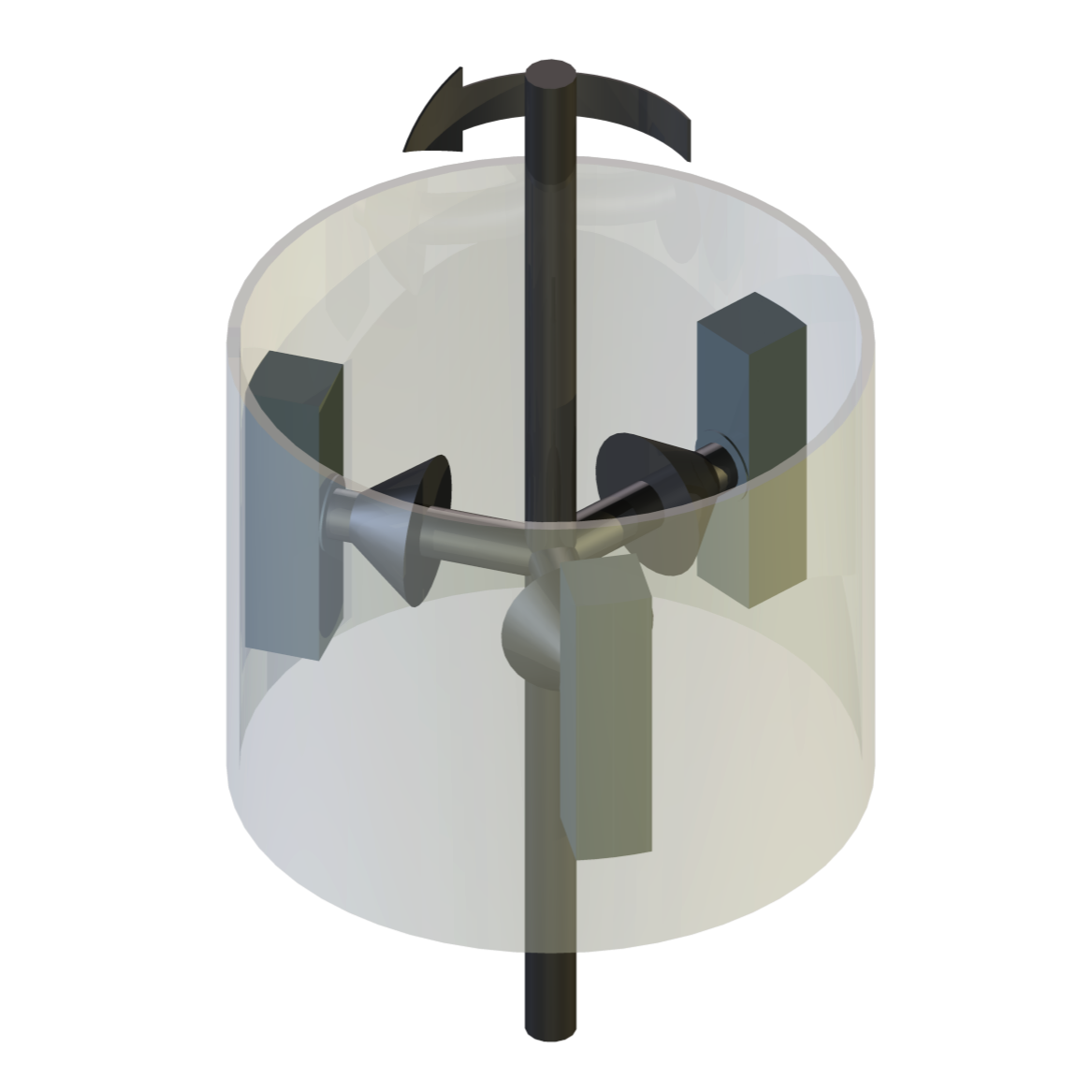

TE 92/AREA/4 Vane Pump Specimen Tooling

The tooling is used in conjunction with TE 92/AREA-L and comprises a non-rotating three-vane specimen carrier in contact with a rotating flat disc. The vanes are independently electrically insulated allowing electrical contact potential measurements to be made between each vane and the rotating disc.

TE 92/AREA/5 Suzuki Test Specimen Tooling

The tooling is used in conjunction with TE 92/AREA-L This adapter comprises a shaft mounting collet for carrying cylindrical tube specimens, which have precision ground ends, and a fixed specimen mount, for square coated plate specimens. Radial grooves machined in the plate specimens allow lubricant entrainment, with lubricant supply via the bath central feed port.

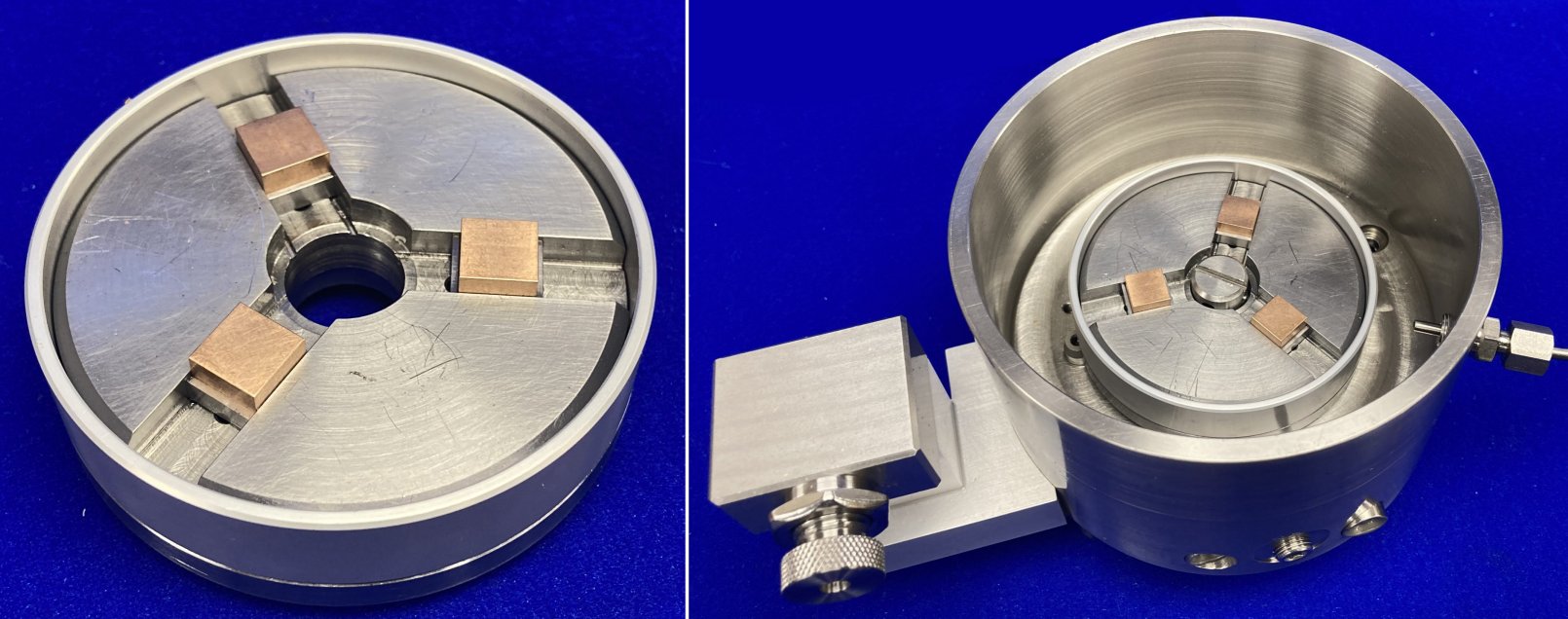

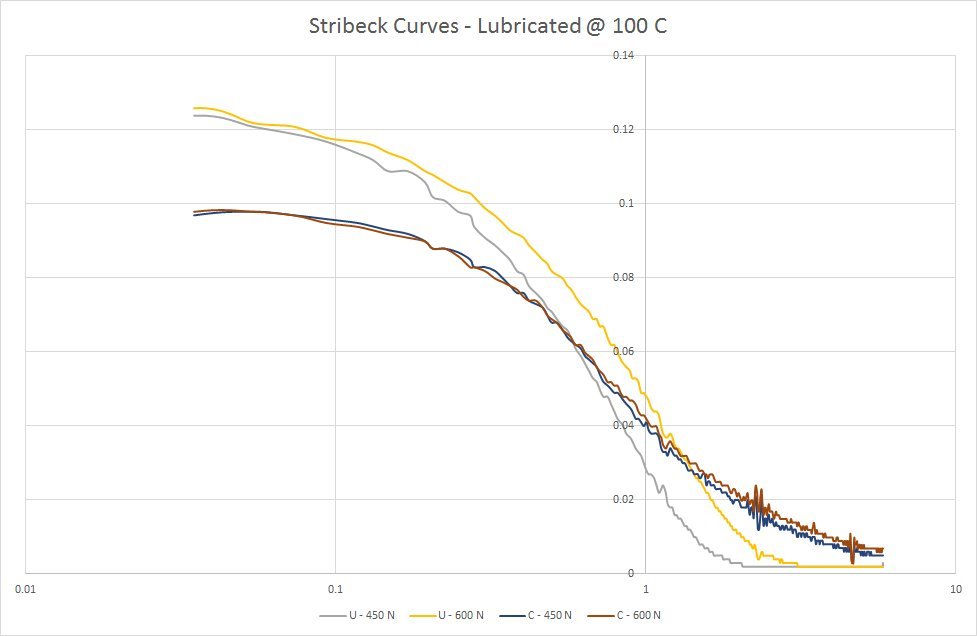

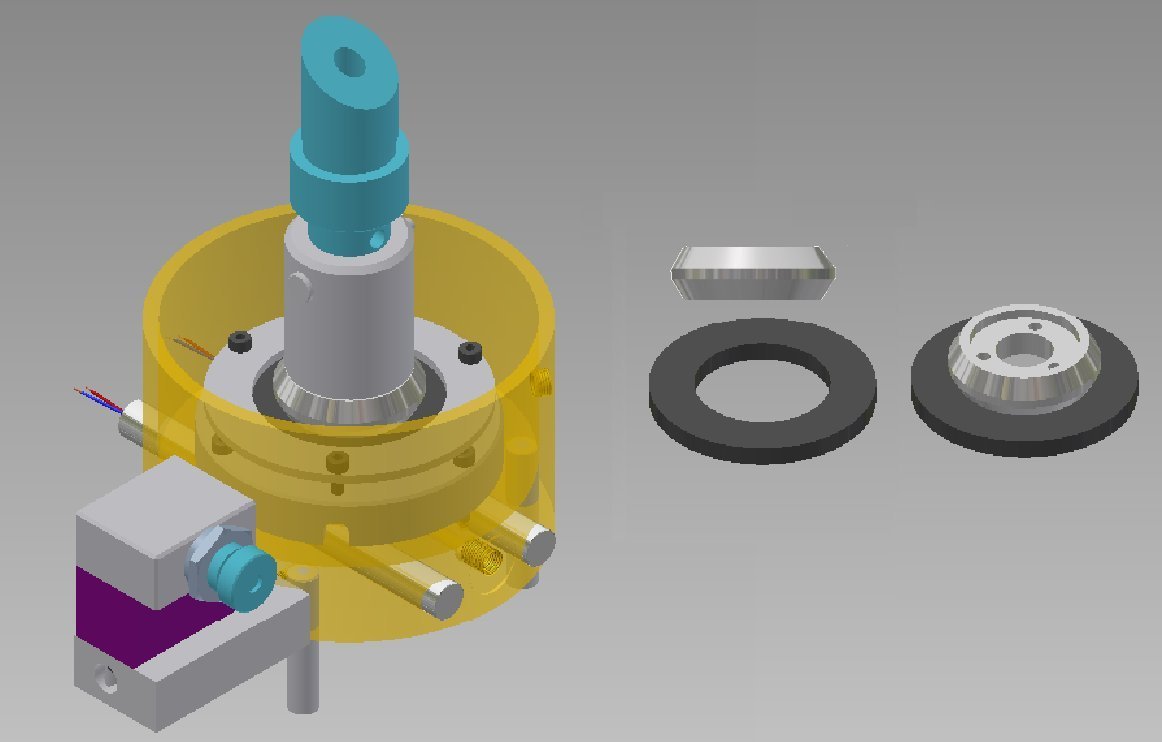

TE 92/AREA/6 Three Pad Thrust Bearing (Stribeck) Tooling

The adapter comprises three taper/flat-land pad specimens, which act in the same way as a conventional taper/flat land thrust bearing. The adapter allows Stribeck curves to be generated in under ten minutes, with less than 250 ml lubricant sample.

TE 92/AREA/7Pump Slipper Shoe Specimen Tooling

This adapter uses slipper shows taken from an actual radial piston pump and is used for evaluating both pump materials and hydraulic fluids.

ROLLING CONTACT FATIGUE TEST GEOMETRIES

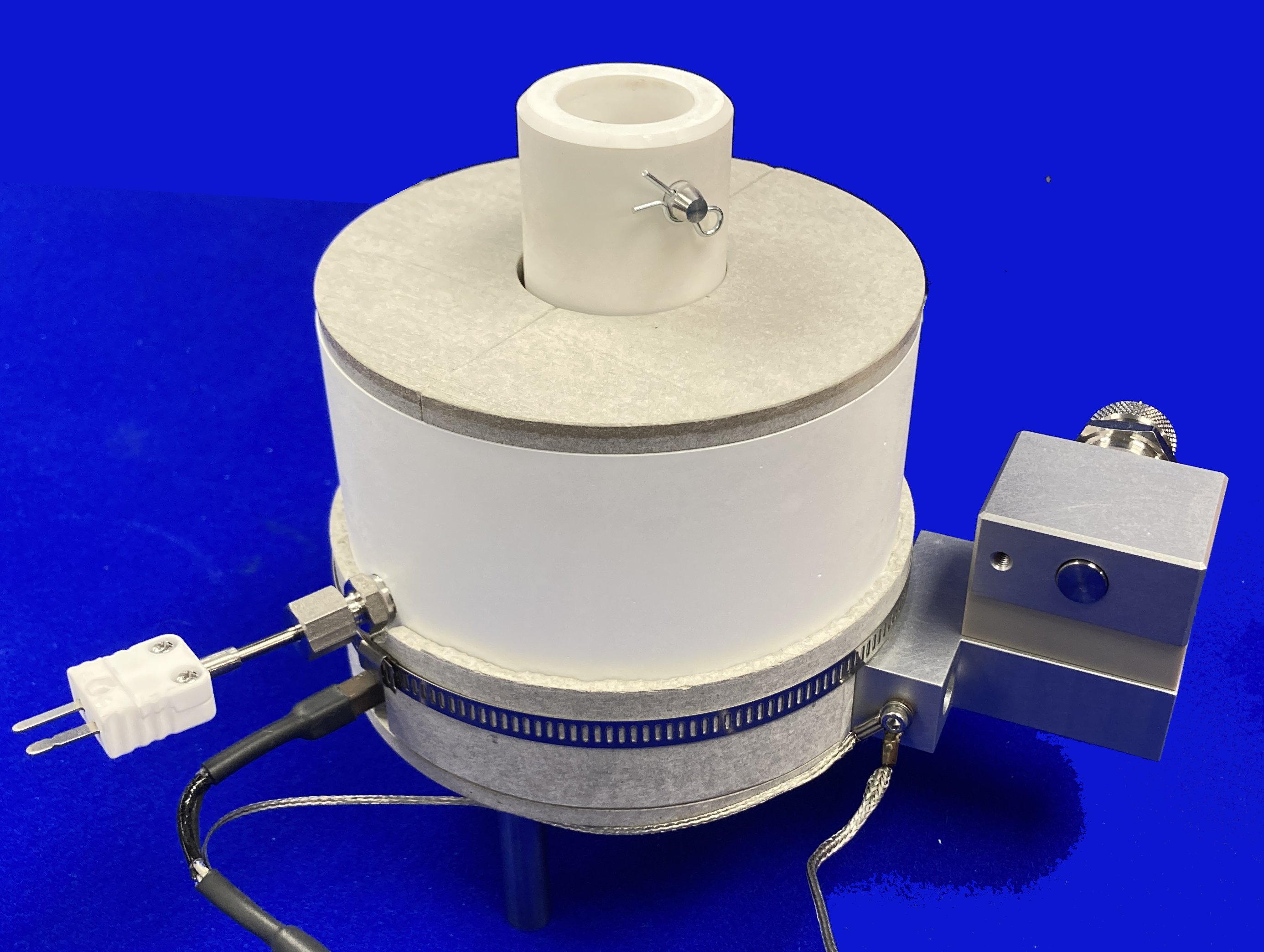

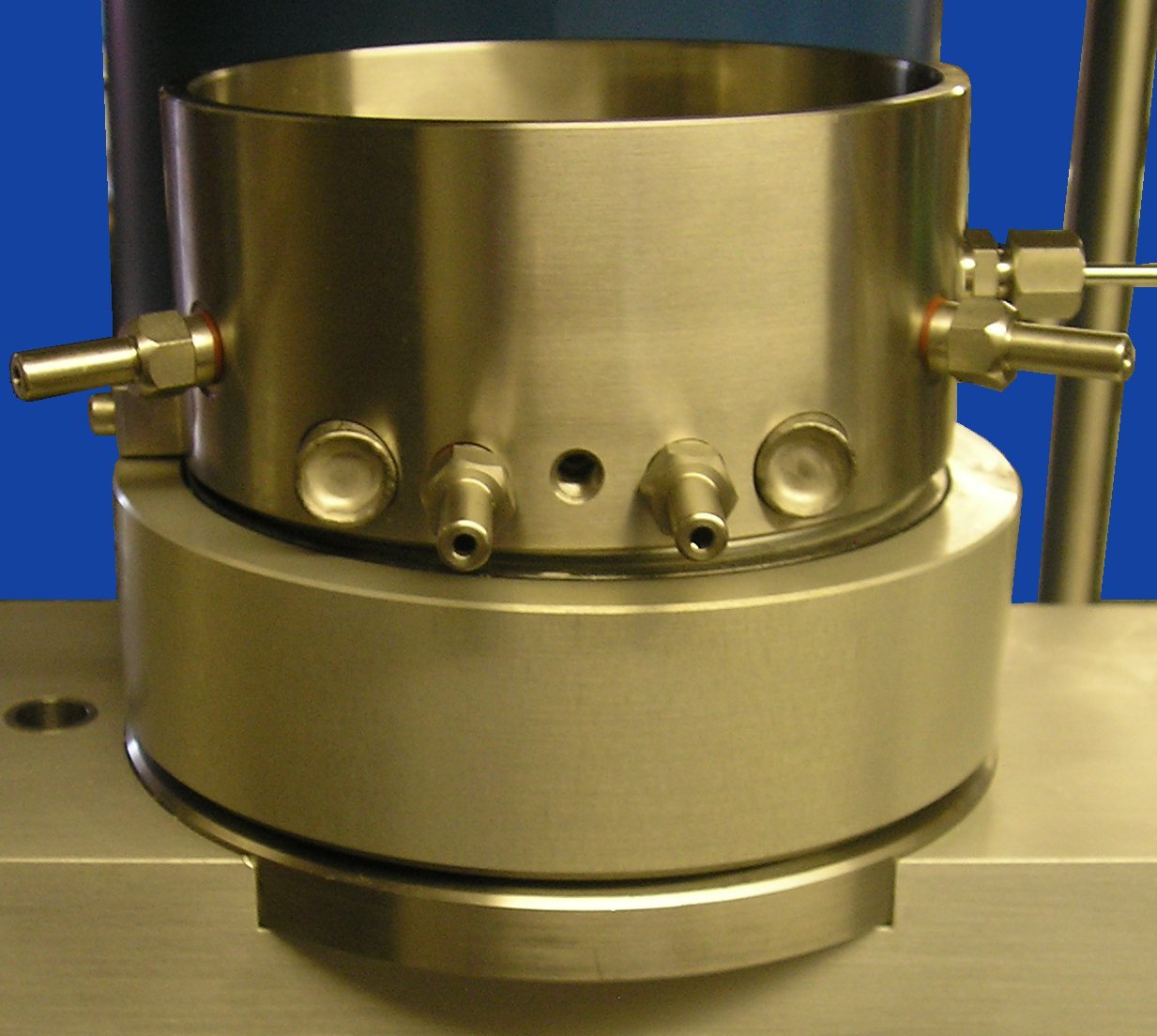

TE 92/RCF Self-aligning Heated Reservoir for RCF Tests

The reservoir is usually used in conjunction with TE 92/2 High Load Actuator. It incorporates cartridge heaters and thermocouple for specimen heating and temperature measurement. It has a central port for lubricant feed and a drain port with an adjustable stand-pipe; the level of fluid is controlled by using press-in a stand-pipe tube of the required length. Test fluid may be fed by gravity or circulated through the enclosure using the TE 92/LS Lubricant Re-circulating System or other suitable circulation system. A lid is provided for the reservoir to minimise loss of fluid by splashing or evaporation.

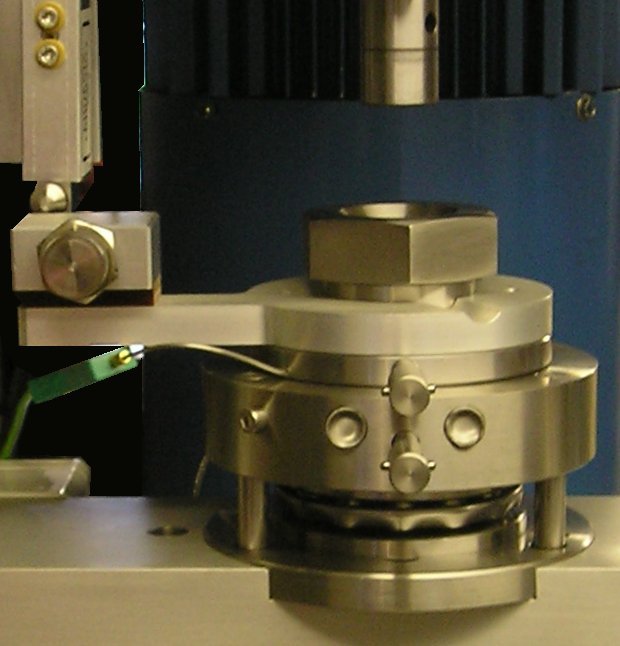

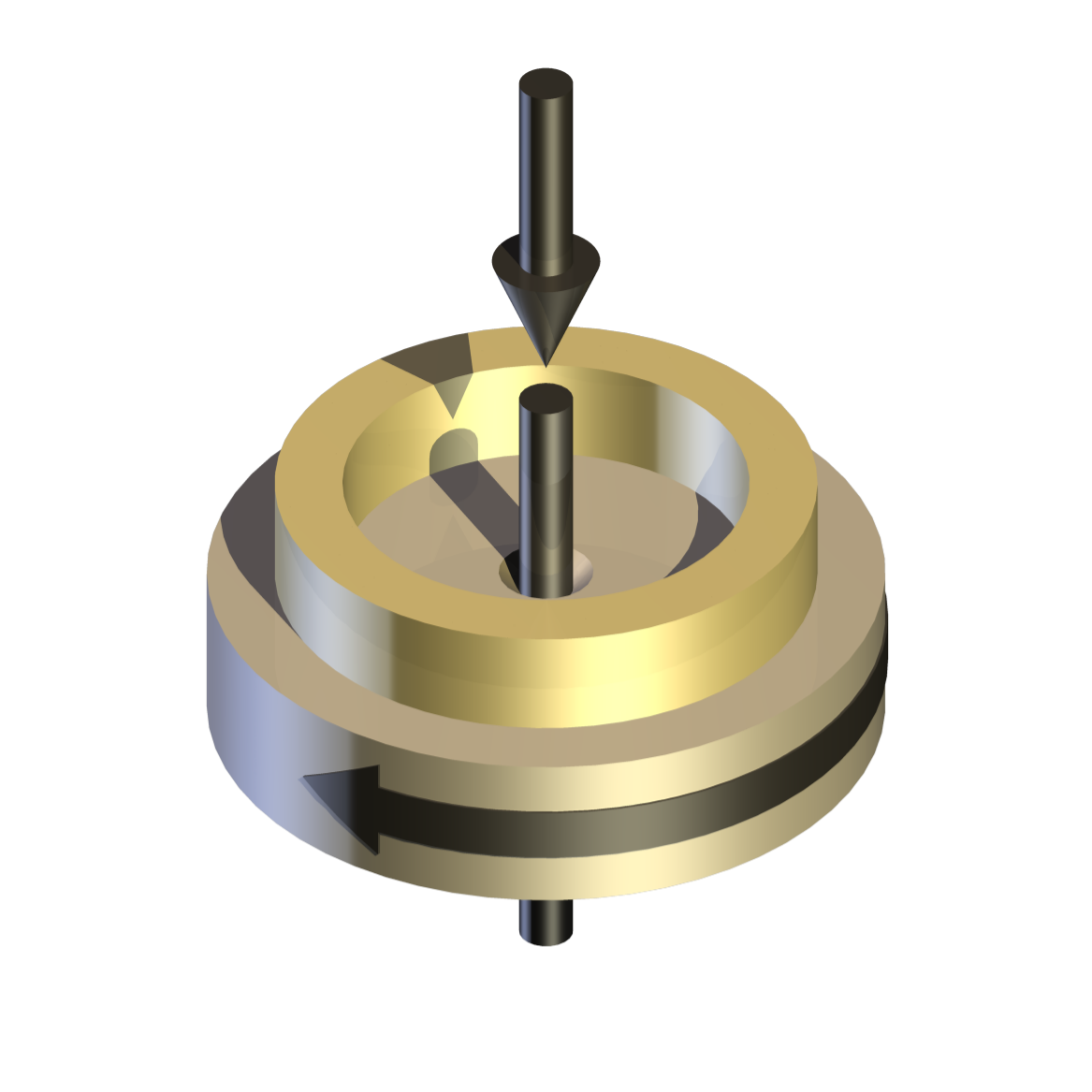

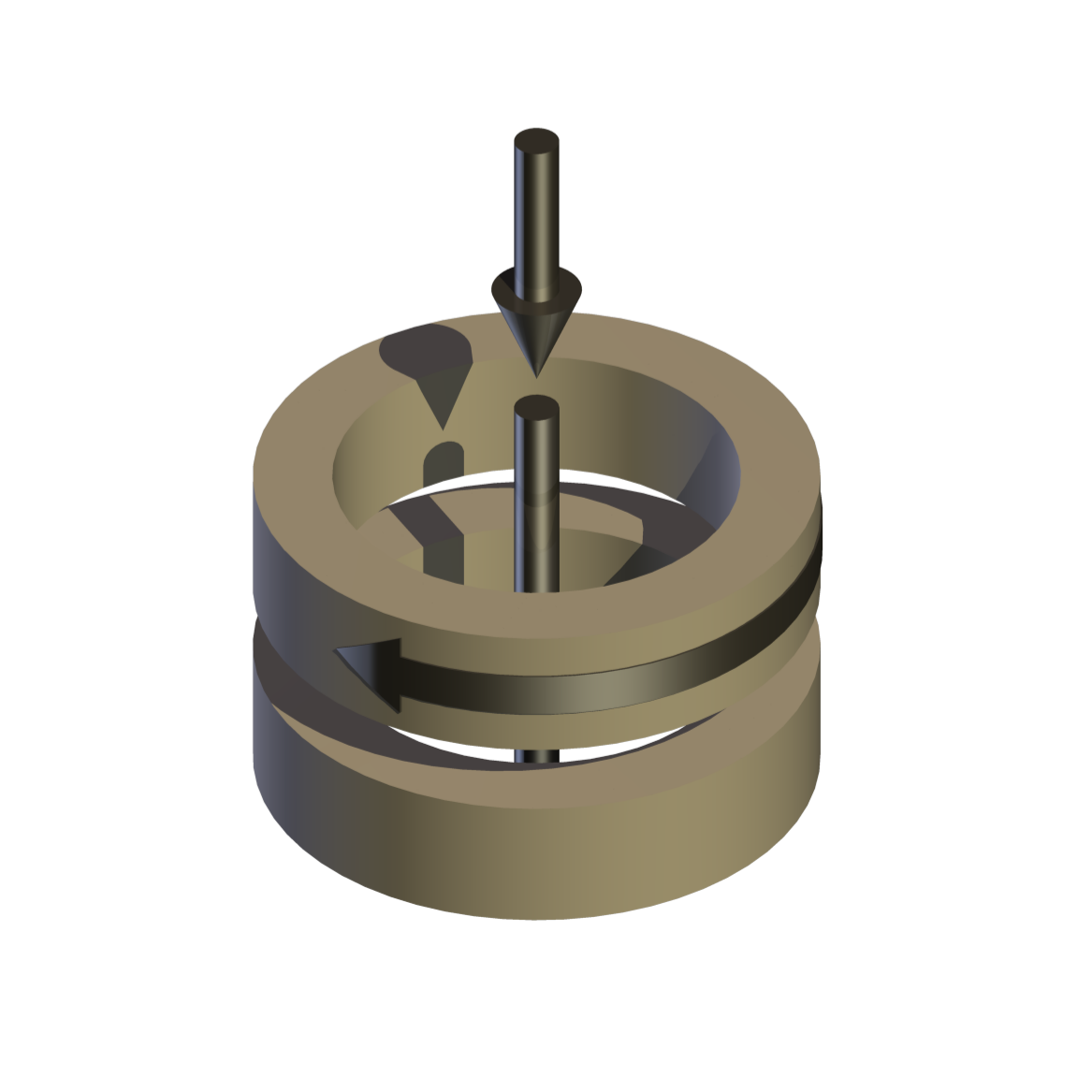

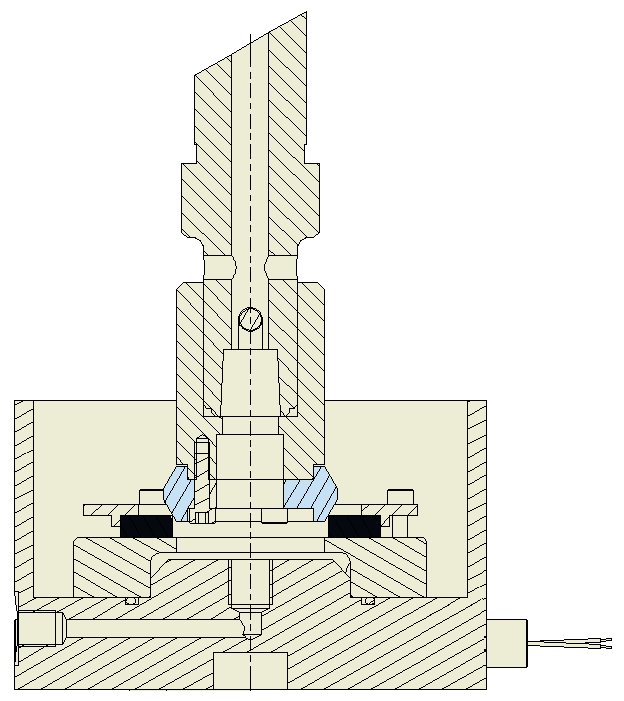

TE 92/RCF/1 Cone on Angular Contact Bearing Tooling

This adapter uses the lower race and cage of a standard angular contact bearing (SKF 7206), with the inner race replaced by a conical specimen. The cone angle is such that the rolling contact is pure rolling with no spin. With silicon nitride balls in the bearing race, contact pressures up to 5.5 GPa can be achieved. The cone is subjected to the highest number of contacts and thus it is the rolling fatigue performance of the cone material that is investigated in this test configuration.

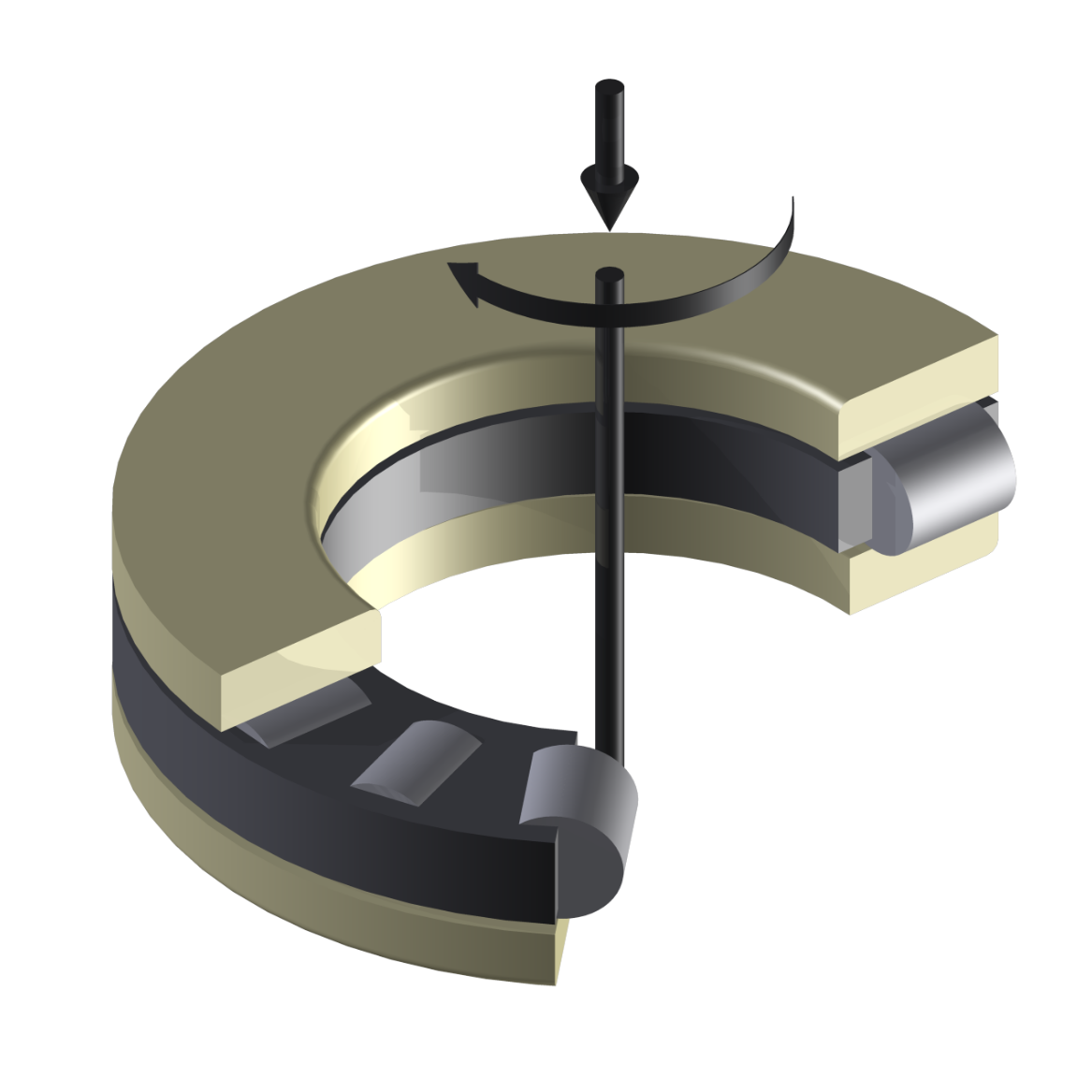

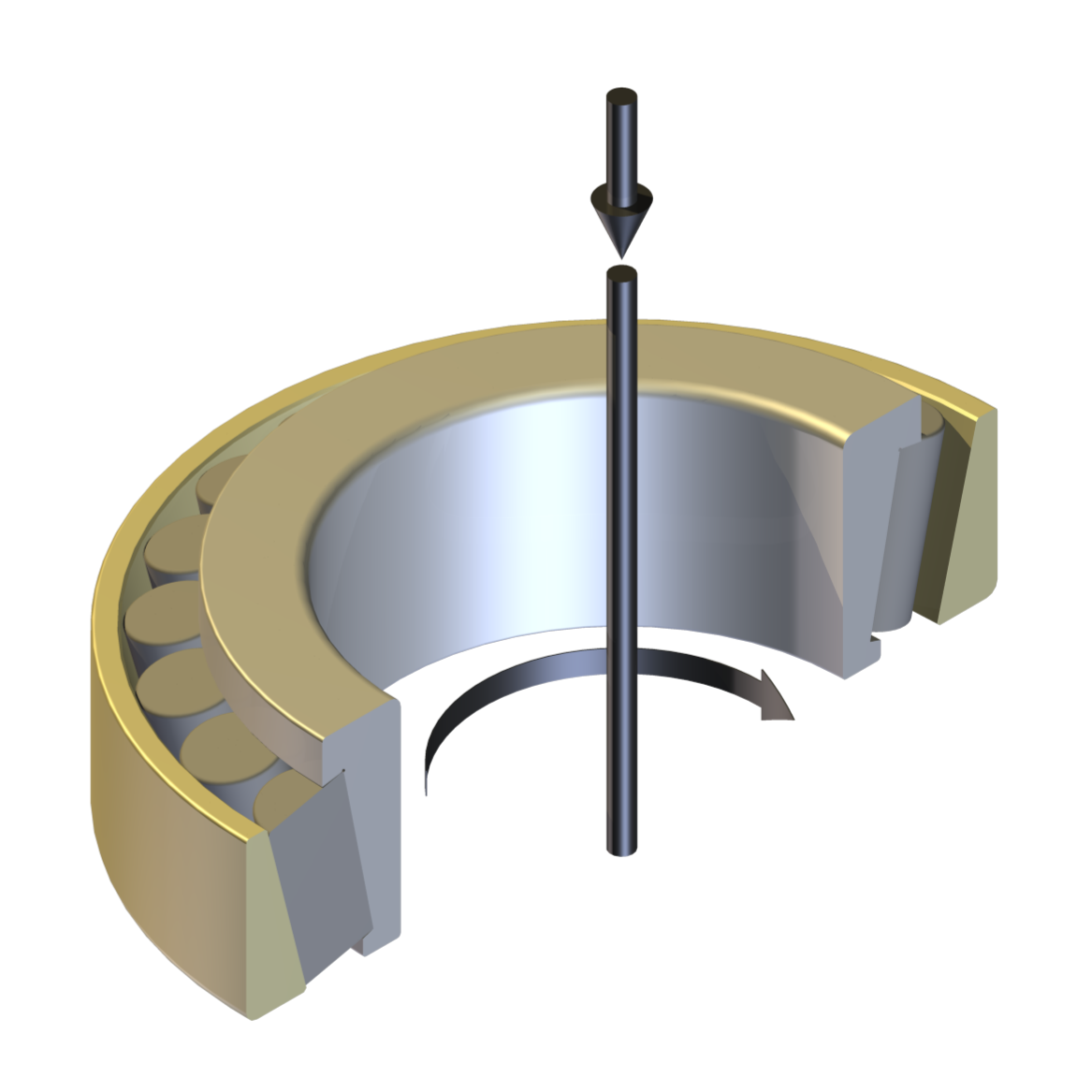

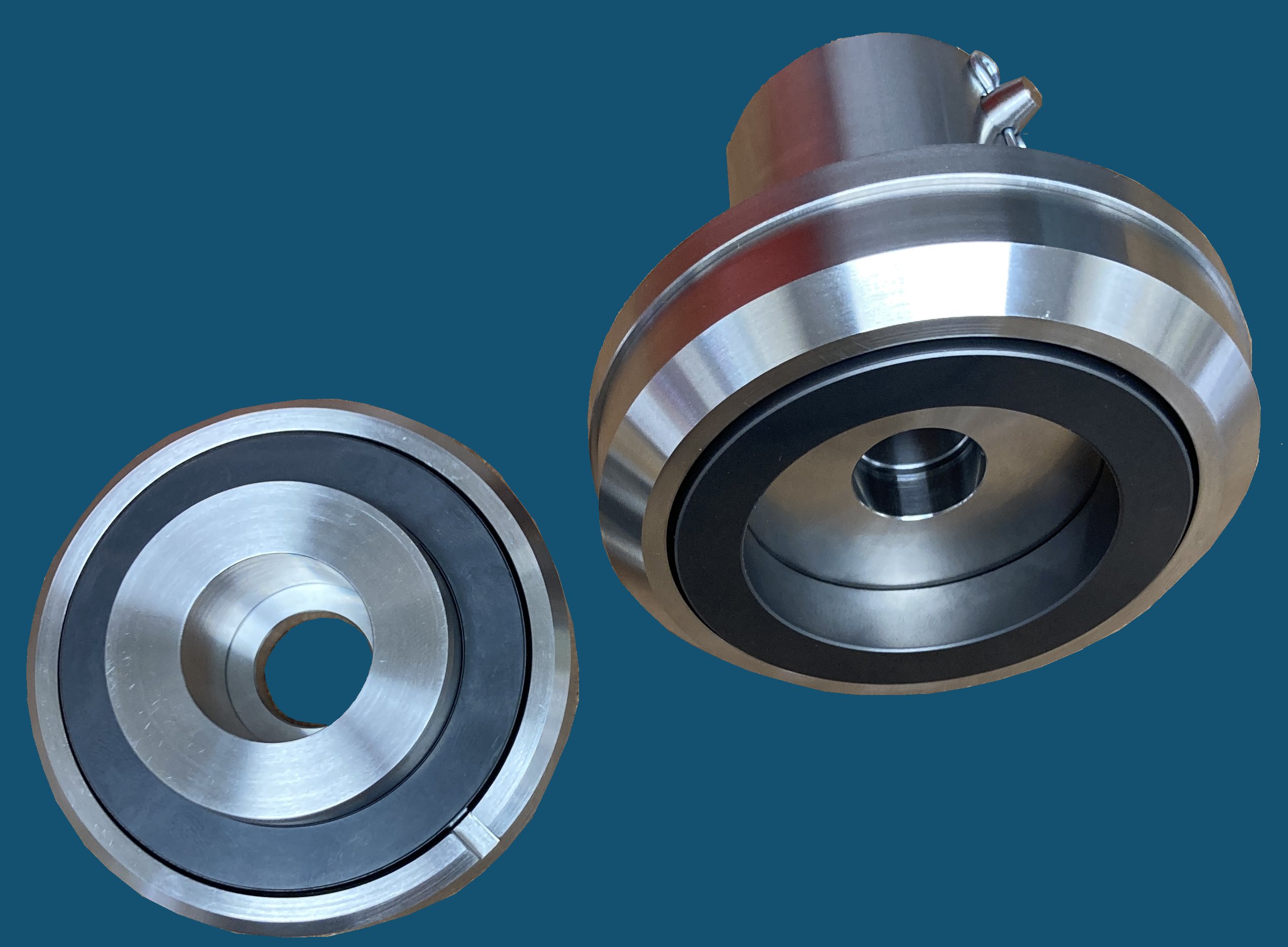

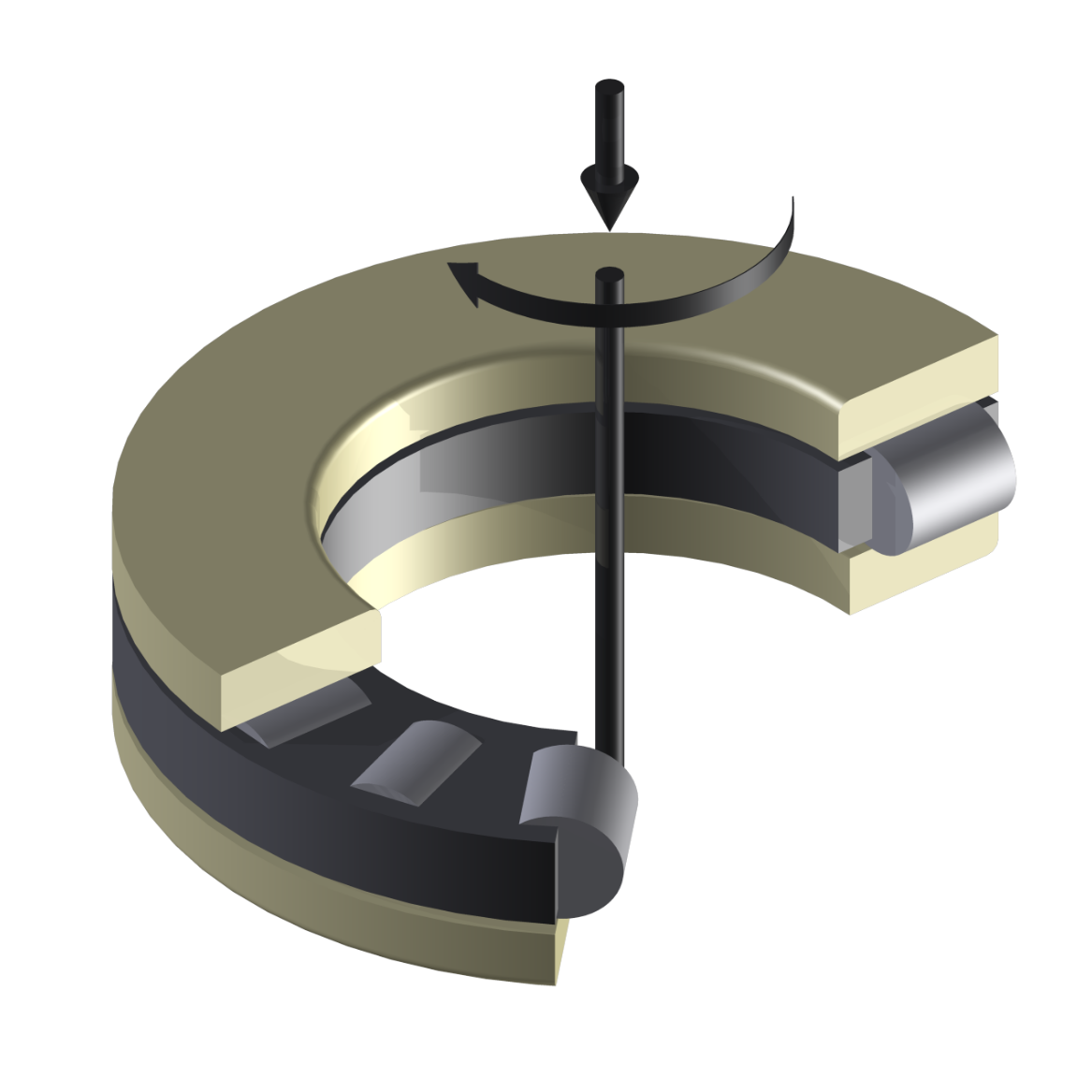

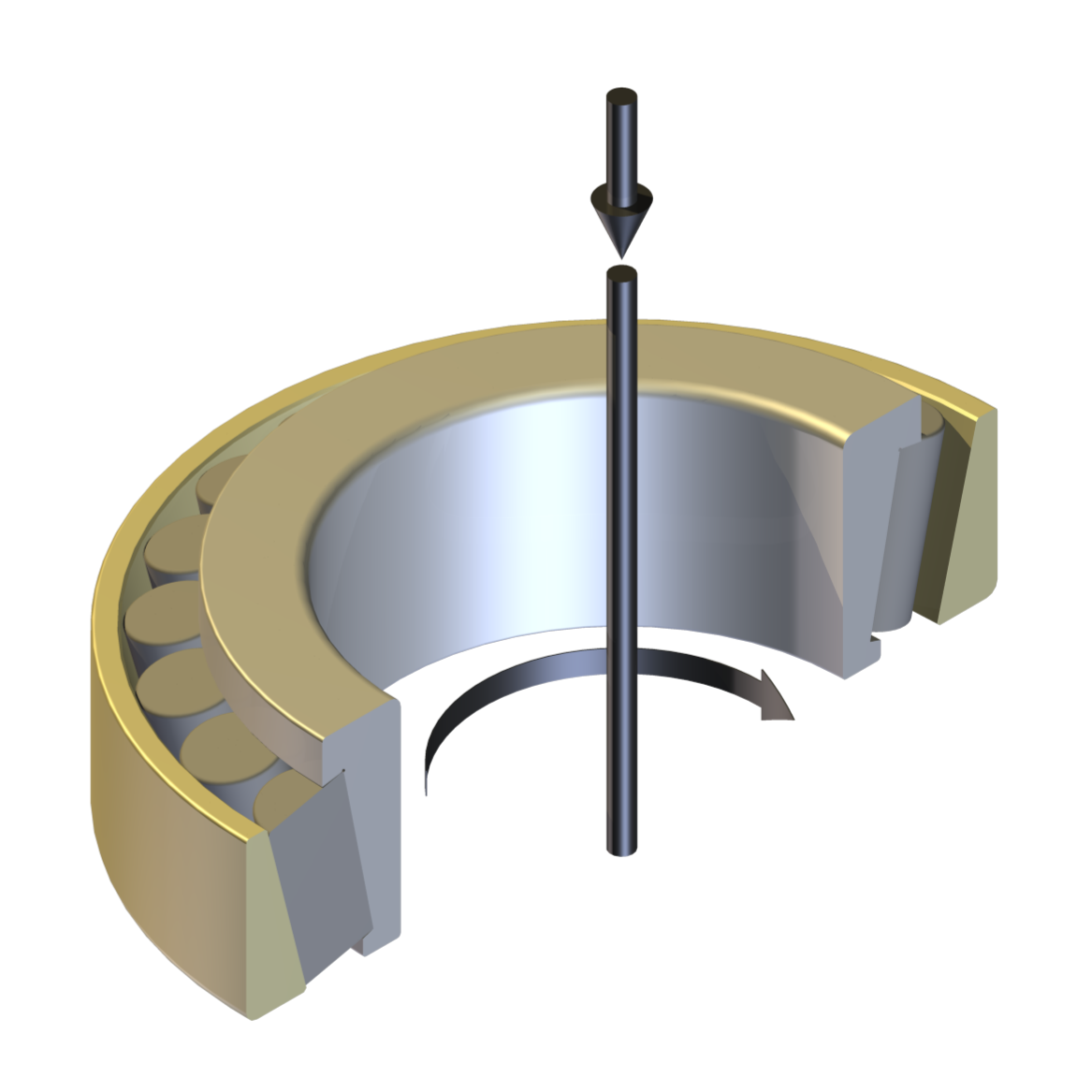

TE 92/RCF/2 Ball Thrust Bearing on Disc Tooling

This adapter uses one half of a standard size 51208 68 mm O/D 40 mm I/D thrust bearing, with the balls running between the normal bearing race and a flat disc. A cage is provided to retain the balls.

TE 92/RCF/3 Roller Thrust Bearing on Disc Tooling

This adapter uses one half of a standard size 81208 TN roller thrust bearing, loaded against a flat lower disc sample, of chosen material. The standard bearing cage is used to locate the rollers, with the cage centred by a spindle mounted deep groove ball bearing.

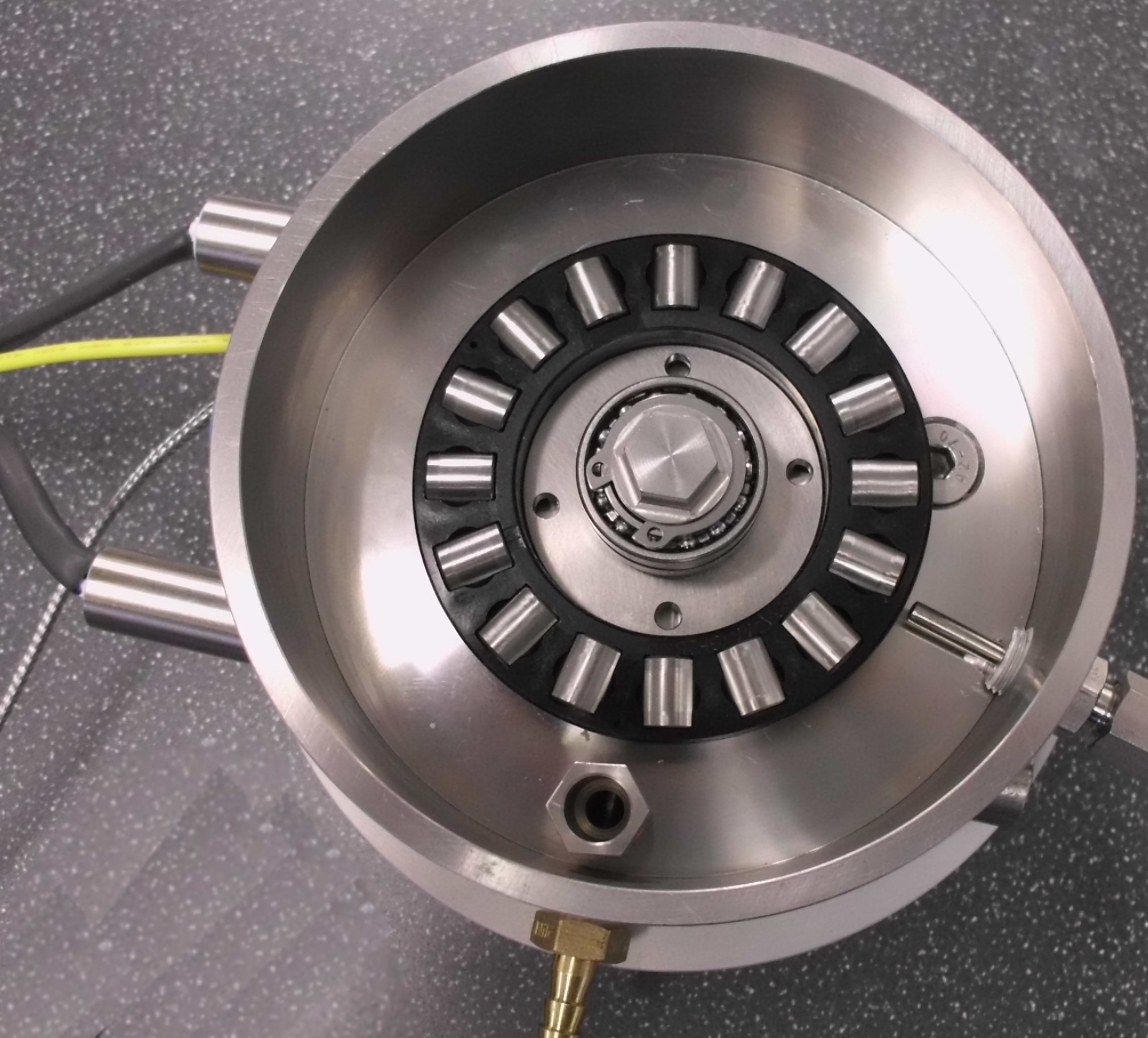

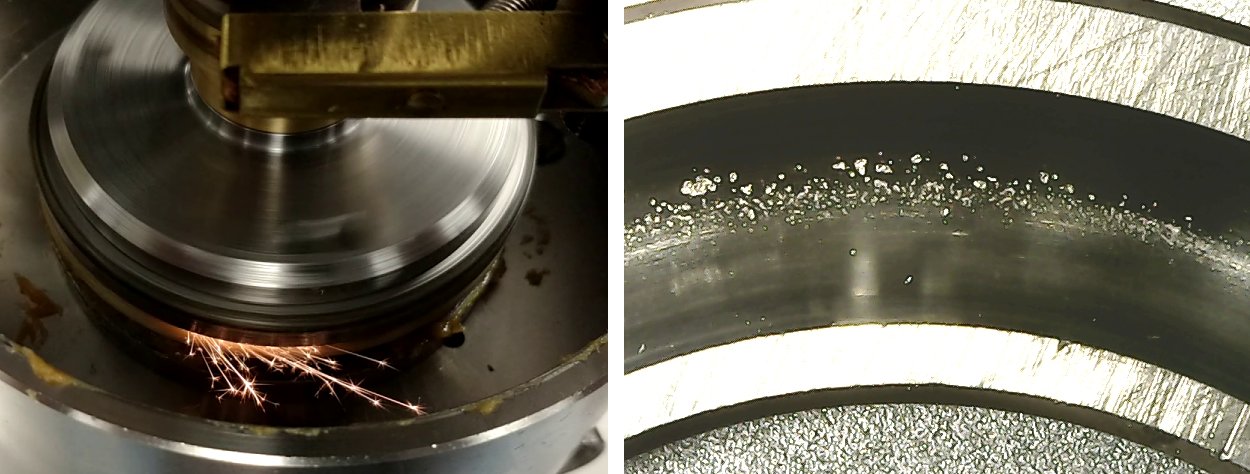

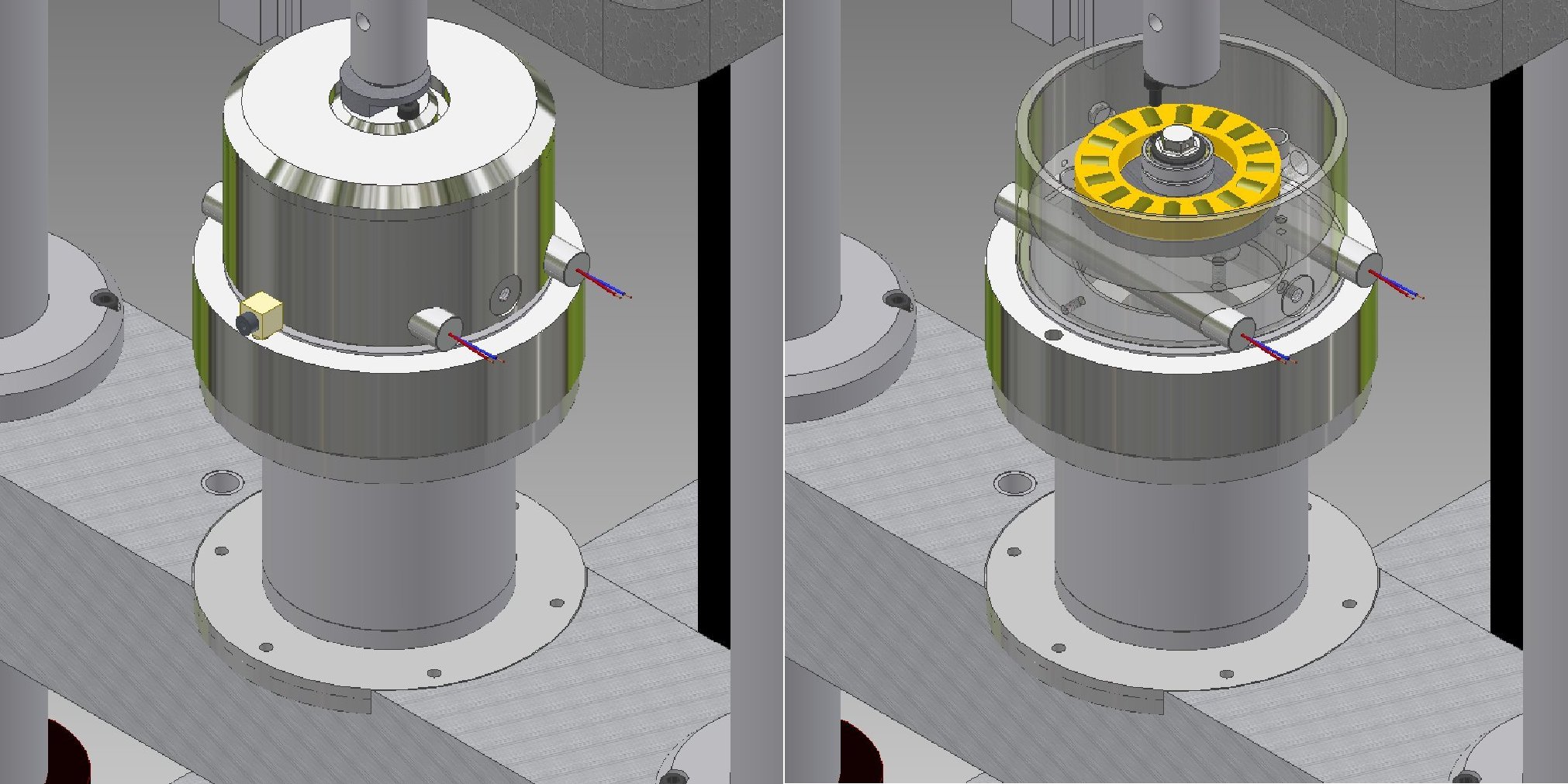

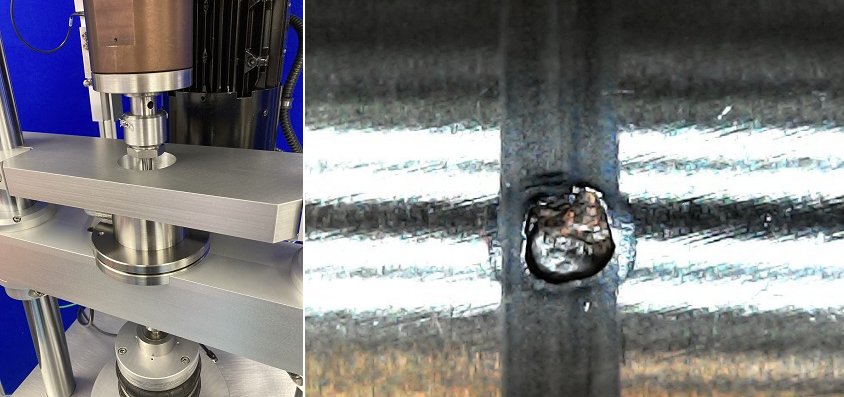

TE 92/RCF/E Electrical Discharge Machining (EDM) Test System

This system is designed to model Electrically Induced Bearing Damage (EIBD) and Electrical Discharge Machining (EDM). It includes a variable voltage source connected, via brush gear, to a commutator, so that the pulse always occurs at the same circumferential position.

The system is used with the ball and roller thrust bearing test geometries, which can either be used with all metal rolling elements or with all but one rolling element replaced with ceramic balls or rollers. This arrangement then ensure that the discharge always occurs through just one rolling element, rather than randomly through multiple rolling elements.

Non-electrically conducting bearing cages are used and other electrical isolation components are necessary and are incorporated in TE 92/RCF/2/E and TE 92/RCF/3/E tooling.

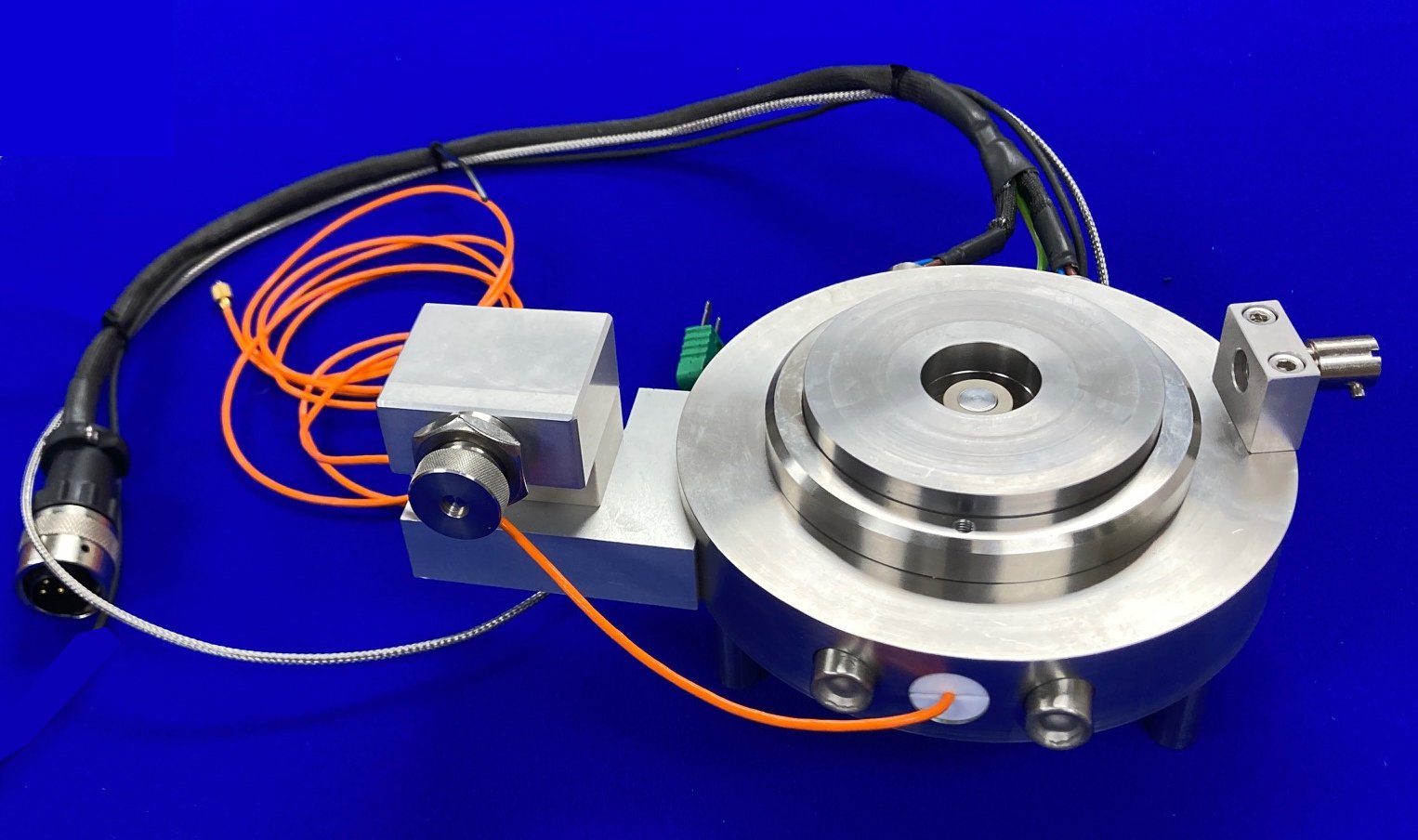

TE 92/RCF/T In-line Rolling Friction Torque Transducer

This is a combined axial load and torque transducer for mounting rolling element bearing test adapters. This allows simultaneous measurement of applied load and torque. Four different sensors are available, with axial force and torque capacities: 1.0 kN – 10 Nm, 2.5 kN – 25 Nm, 5.0 kN – 50 Nm and 10.0 kN – 100 Nm.

SPECIAL PURPOSE TEST ADAPTERS

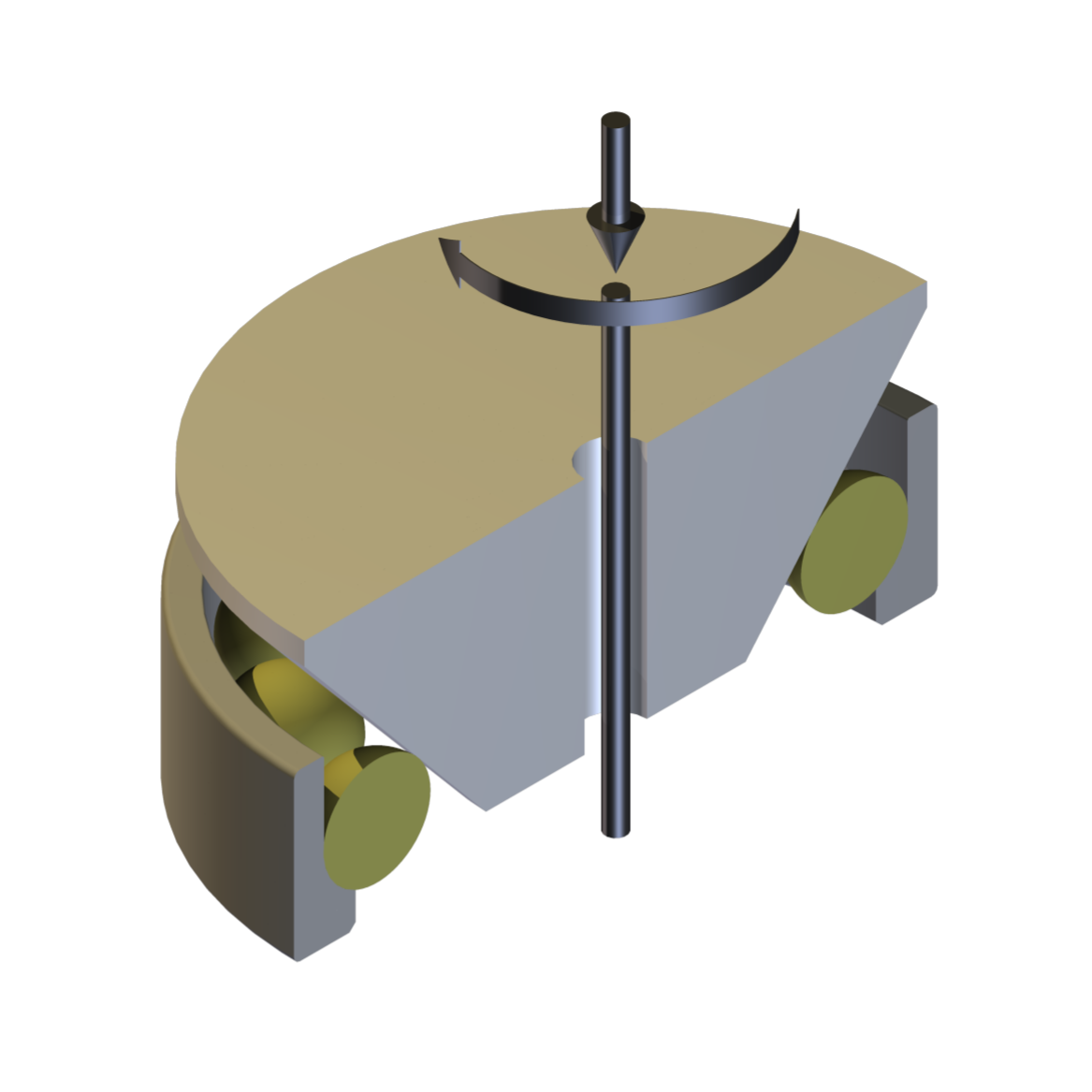

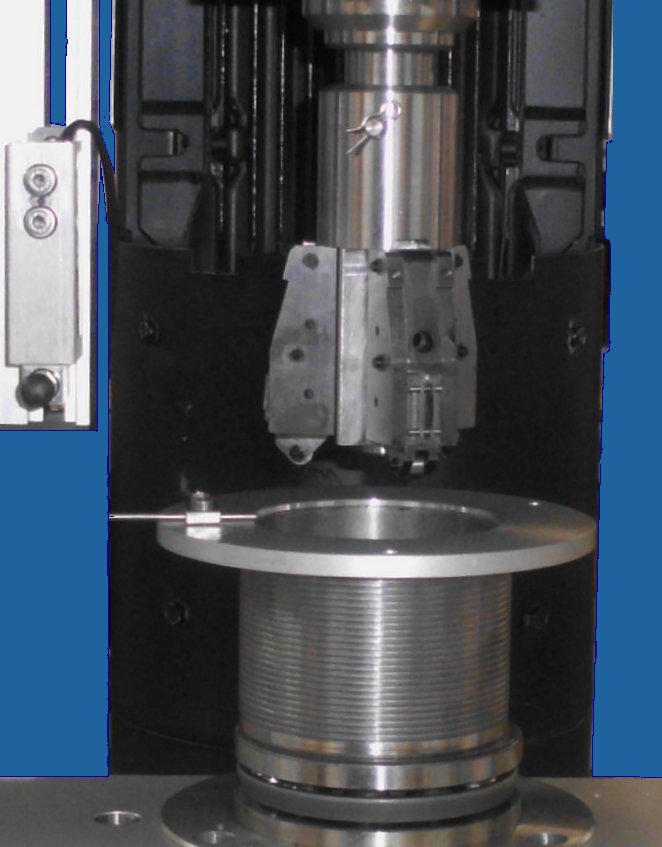

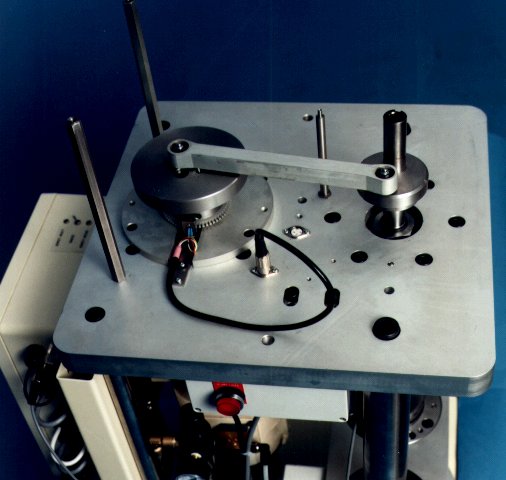

TE 92/PV Pin on Vee Block/Bock on Ring Adapter

This adapter converts the machine from axial to radial loading test configuration. The adapter comprises This adapter converts the machine from axial to radial loading test configuration. The adapter comprises a linear slide assembly, which moves radially with respect to the spindle axis. The slide assembly incorporates two specimen carriers, allowing two identical specimens (vee, flat or conforming blocks) to be loaded on either side of a pin or ring specimen, carried on the spindle. Load is applied by means of servo controlled pneumatic bellows, with force transducer feedback, acting on a double lever mechanism.

The complete assembly is carried on a trunnion bearing on the crossbeam and is torque reaction mounted for friction torque measurement. A heater bath is provided for controlling sample fluid temperature. A displacement transducer is provided to measure the relative movement of the two specimen carriers.

With a half journal bearing contact configuration (which includes conforming block on ring), the point of peak pressure is not on the centre line. This results in the inlet closing over, preventing lubricant entering the bearing contact and causing starved lubrication. Designers of tilting pad partial journal bearings address this problem by designing bearings with the required “pre-load” and “off-set”. Custom tooling can be provided for partial bearing test geometries.

TE 92/LL Precision Low Load Adapter

The precision low load adapter comprises a fixed cross beam, with pneumatic bellows and an integral air bearing, allowing precision low load tests to be run at loads down to 1 N. The maximum load is 1000 N.

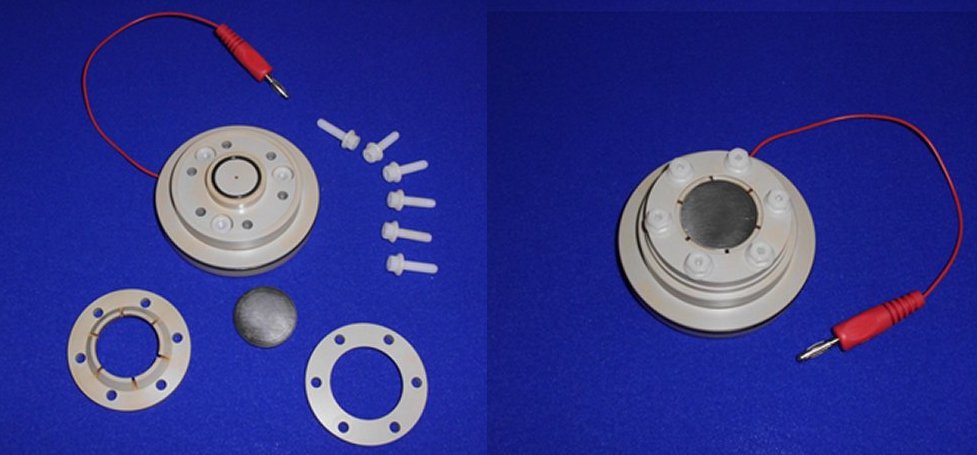

TE 92/EC Electro-chemical Cell & Potentiostat

The electro-chemical test cell allows tests to be run with three rotating ball on disc/pin on disc configurations. It includes a precision low load adapter (1 to 1,000 N) with pneumatic bellows and air bearing, Faraday cage, temperature-controlled fluid circulator and precision shaft slip-rings. A silver/silver chloride reference electrode and a platinum mesh counter electrode are included. The disc specimen is used as a working electrode in a typical three electrode system. The disc is carried on a clamp assembly, designed to avoid crevice corrosion. Electrical contact is made with the disc by means of a spring loaded, gold plated, pin.

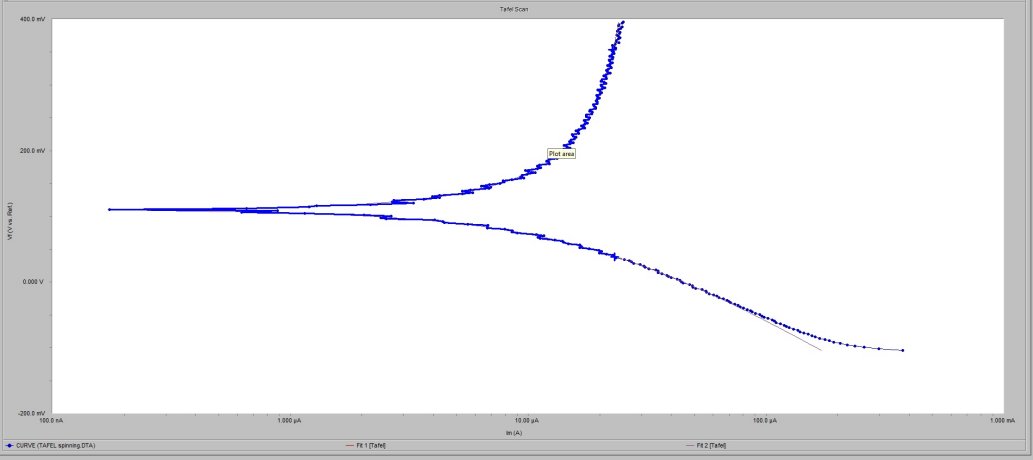

The potentiostat, which is triggered by COMPEND, is a Gamry Instruments Reference 600 Potentiostat/Galvanostat/ZRA and is supplied with licenses for the following software:

- • DC105 DC Corrosion

- • CPT110 Critical Pitting Temperature

- • EN120 Electrochemical Noise Experiment

- • EFM140 Electrochemical Frequency Modulation

- • PHE200 Physical Electrochemistry

- • PV220 Pulse Voltammetry

- • EIS300 Electrochemical Impedance,

- • ESA410 Electrochemical Signal Analyzer

- • VFP600 Virtual Front Panel

- • PWR800 Electrochemical Energy

Gamry Echem Analyst software is used to process the data and provide Tafel fit calculation to yield polarisation resistance Rp, Tafel Constants βa and βc, wear corrosion rate C (Co and Cw), together with the Open circuit potential Ecor, and current icor, from the OCP experiment.

Test sequences are provided for experiments in accordance with ASTM G199 “Standard Guide for determining Synergism between Wear and Corrosion”.

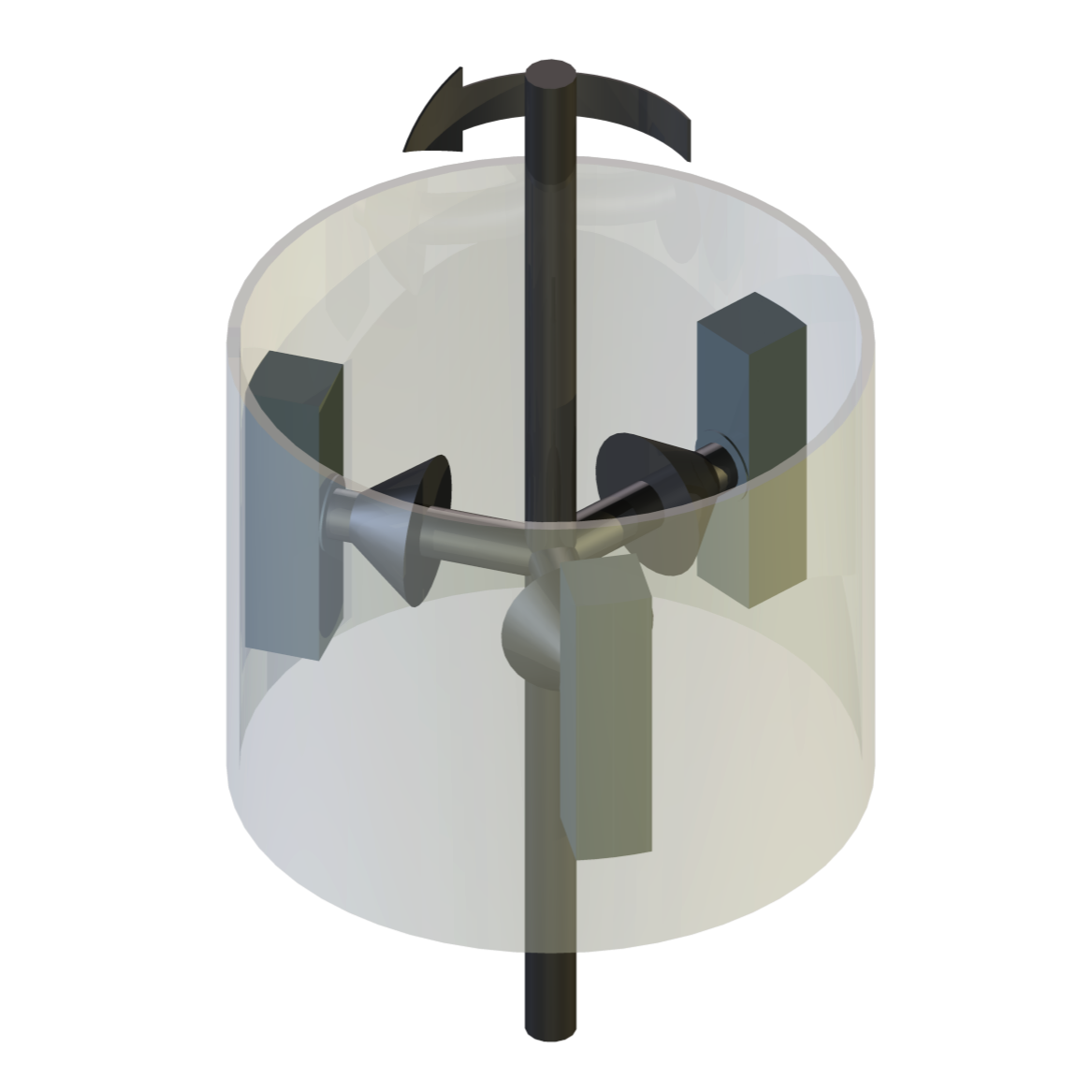

TE 92/SA/1 Three Station Ring on Liner Adapter

Instead of running up and down the liner, the ring samples are run around the internal circumference of a section of liner in either continuous rotation, allowing high sliding speeds to be achieved, or oscillating motion.

The adapter incorporates a fixed section of liner, which forms the specimen bath wall, and a rotating ring sample carrier. Lubricant may be dripped down the wall of the liner section, which is heated with a band heater.

The ring sample carrier has three locations for mounting ring samples. Each ring sample is carried in a lever arm with a pivot point at one end and a roller bearing at the other, the latter engaging with a 45-degree cone, mounted on spline shaft. Applying an axial load to the carrier, results in equal radial load between ring samples and liner. The adapter is used in conjunction with the TE 92/1 Low Load Actuator.

The ring samples, which provide a straight-line contact equivalent to a ring of infinite diameter, are carried in two dimensional spherical seats, allowing self-aligning action.

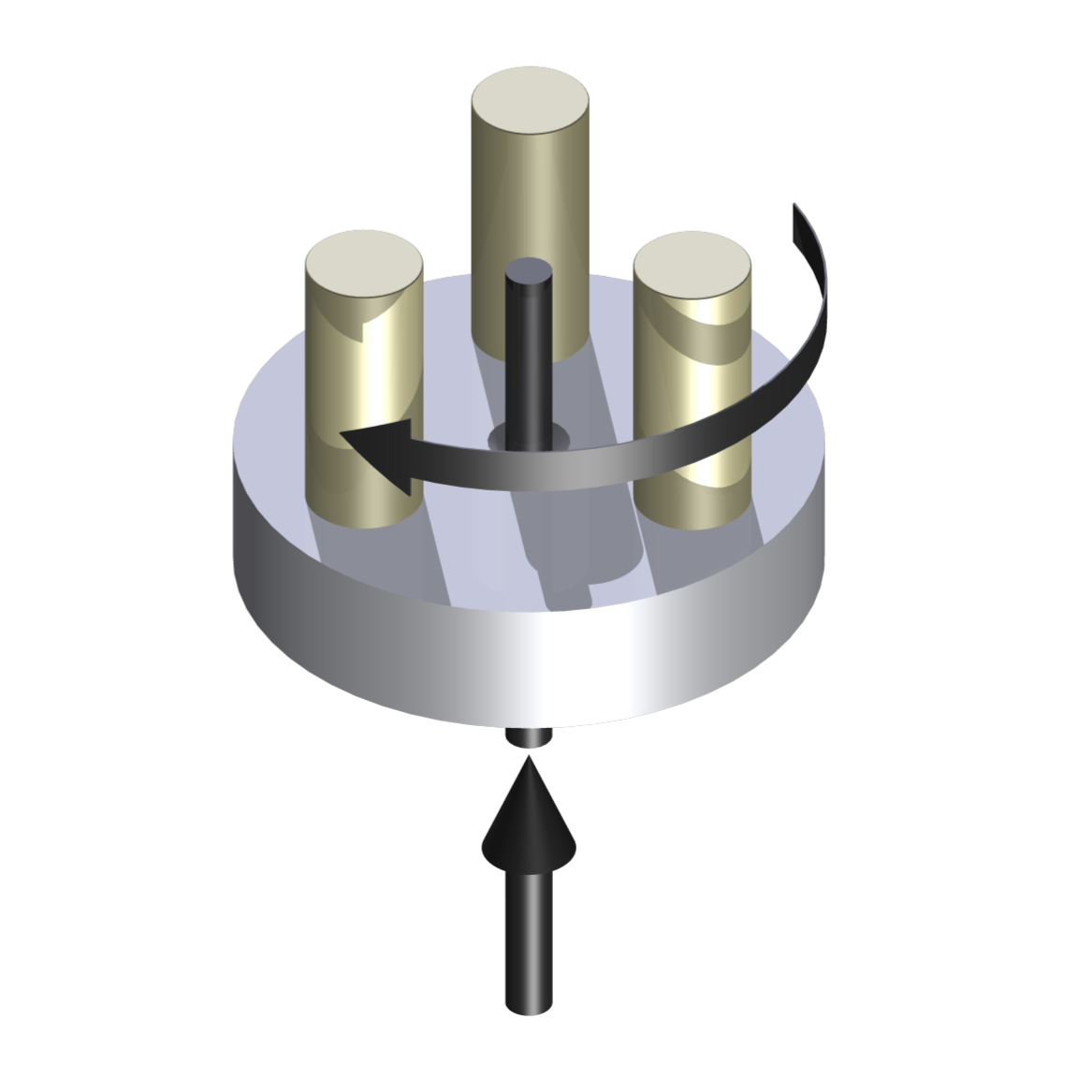

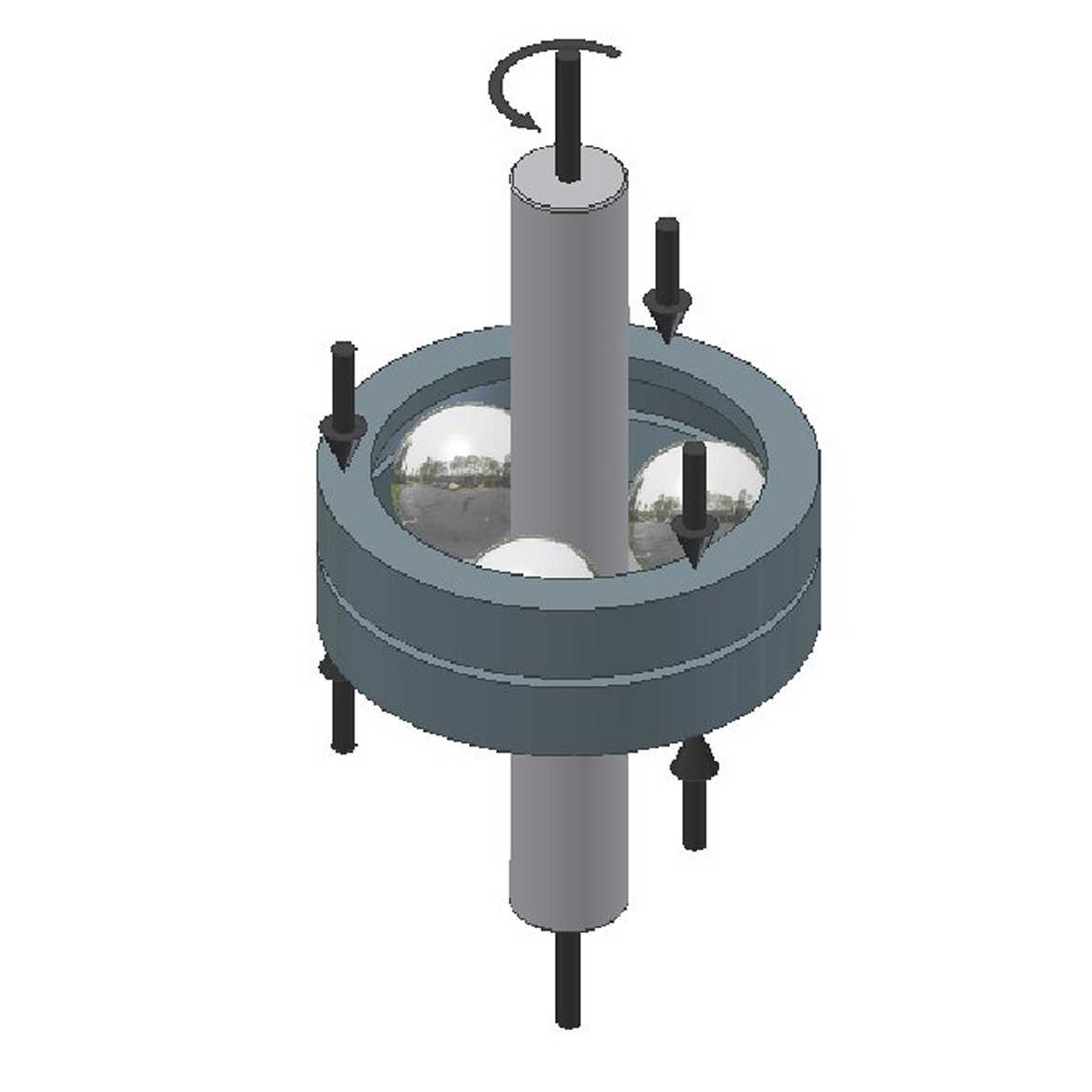

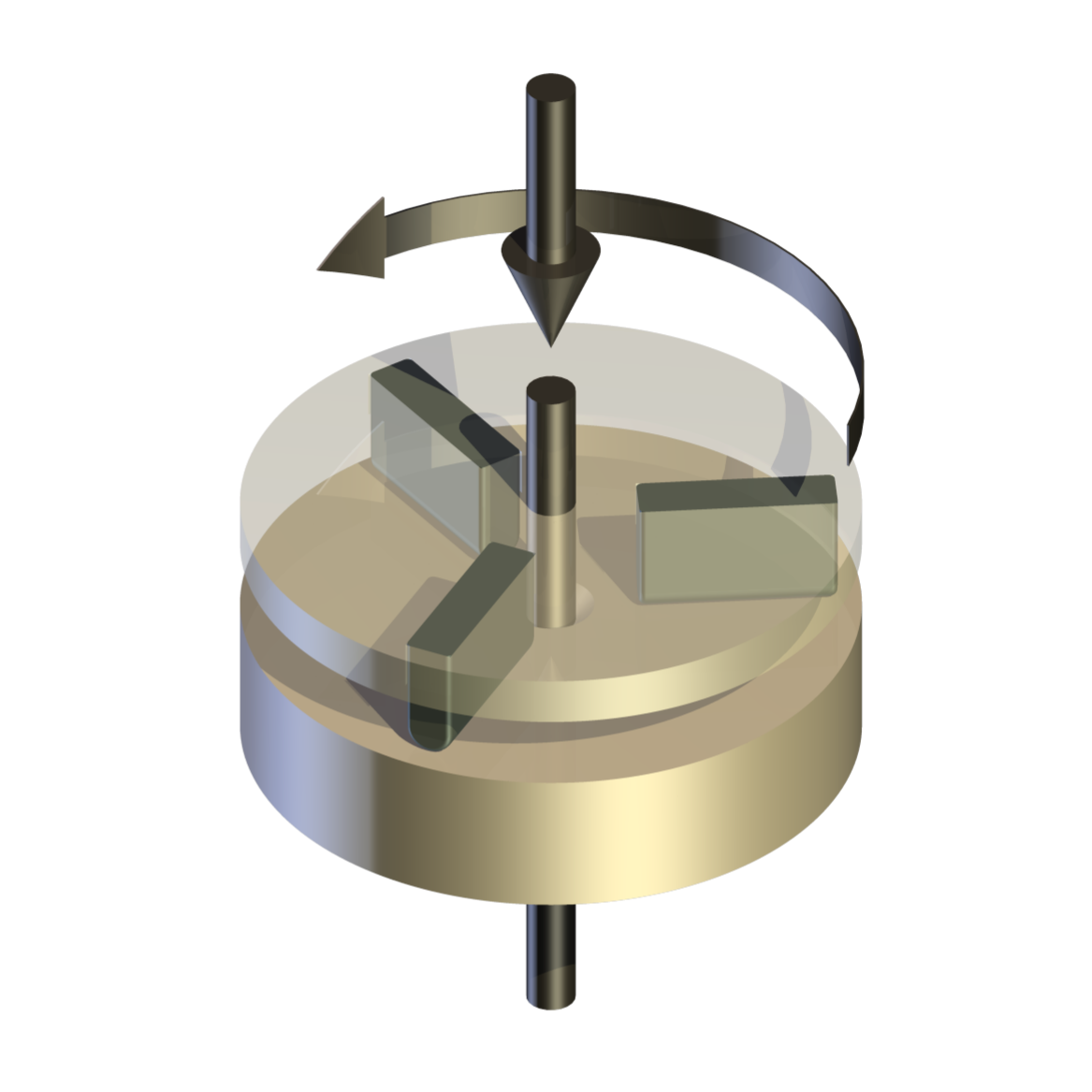

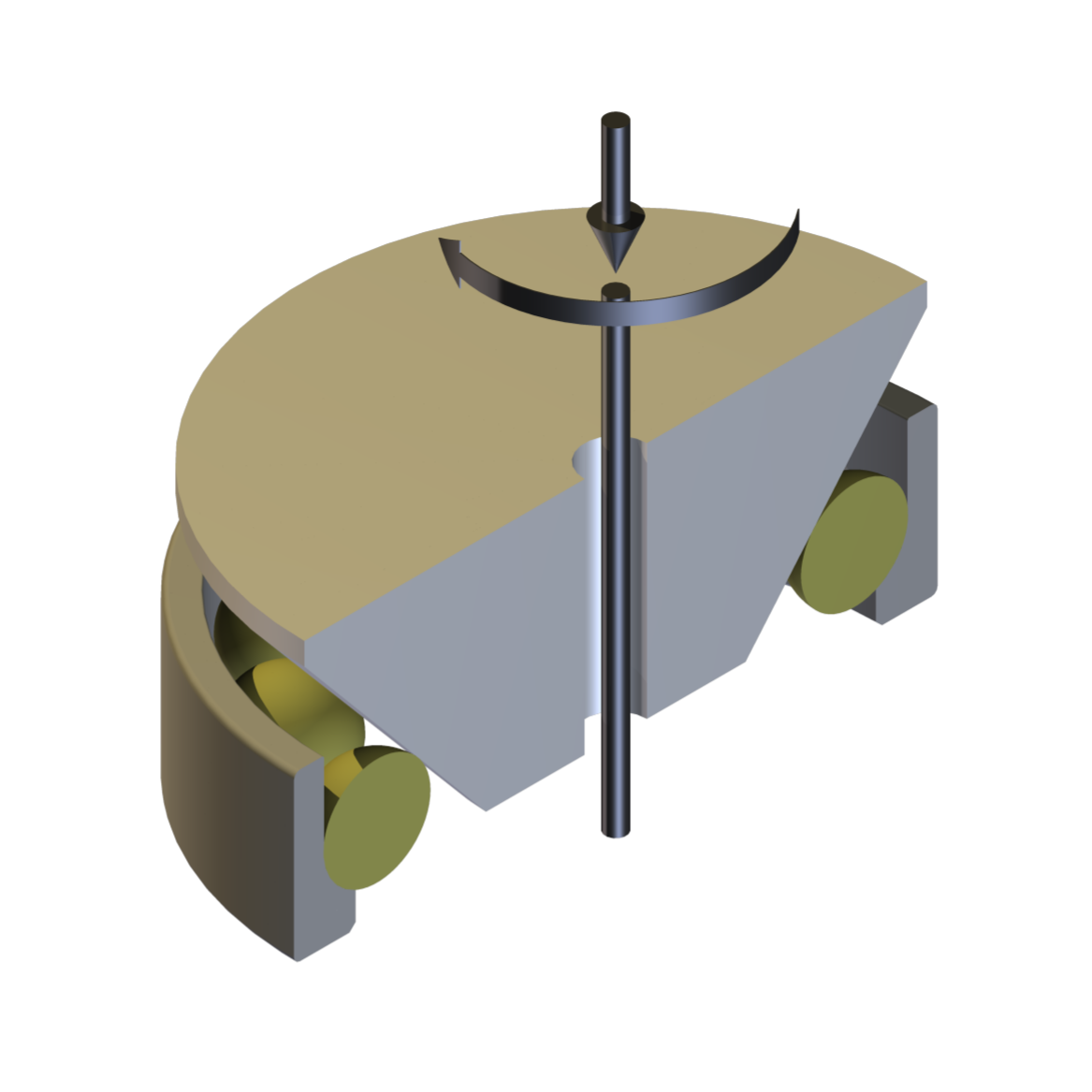

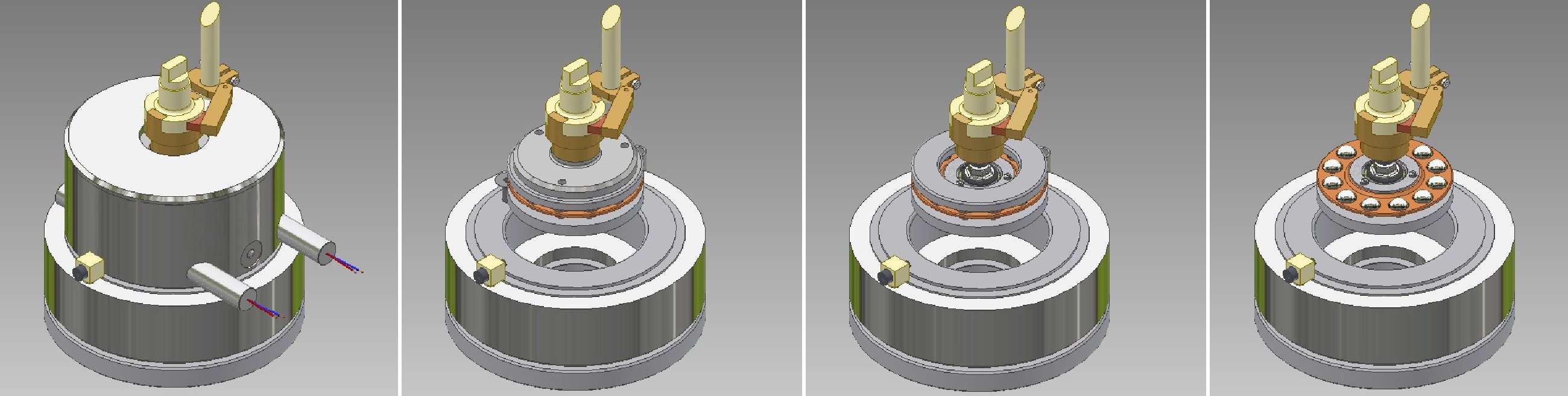

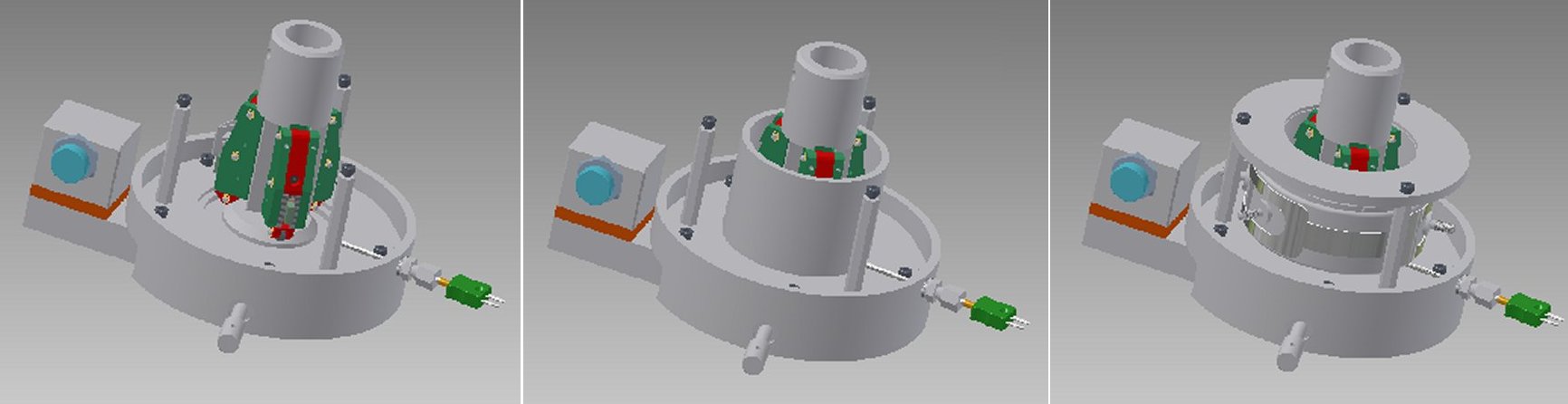

TE 92/SA/2 Three Ball on Rod Rolling Contact Fatigue

This adapter is designed to run the standard three ball on rod rolling contact fatigue test geometry, in which three balls, separated by a retainer, are loaded against a rotating rod specimen, by applying an axial force across two taper bearing cups, mounted above and below the three balls. The original design, dating from the 1970s, used pre-set compression springs to apply the axial load; in this application, the axial load is generated using the TE 92/1 Low Load Actuator.

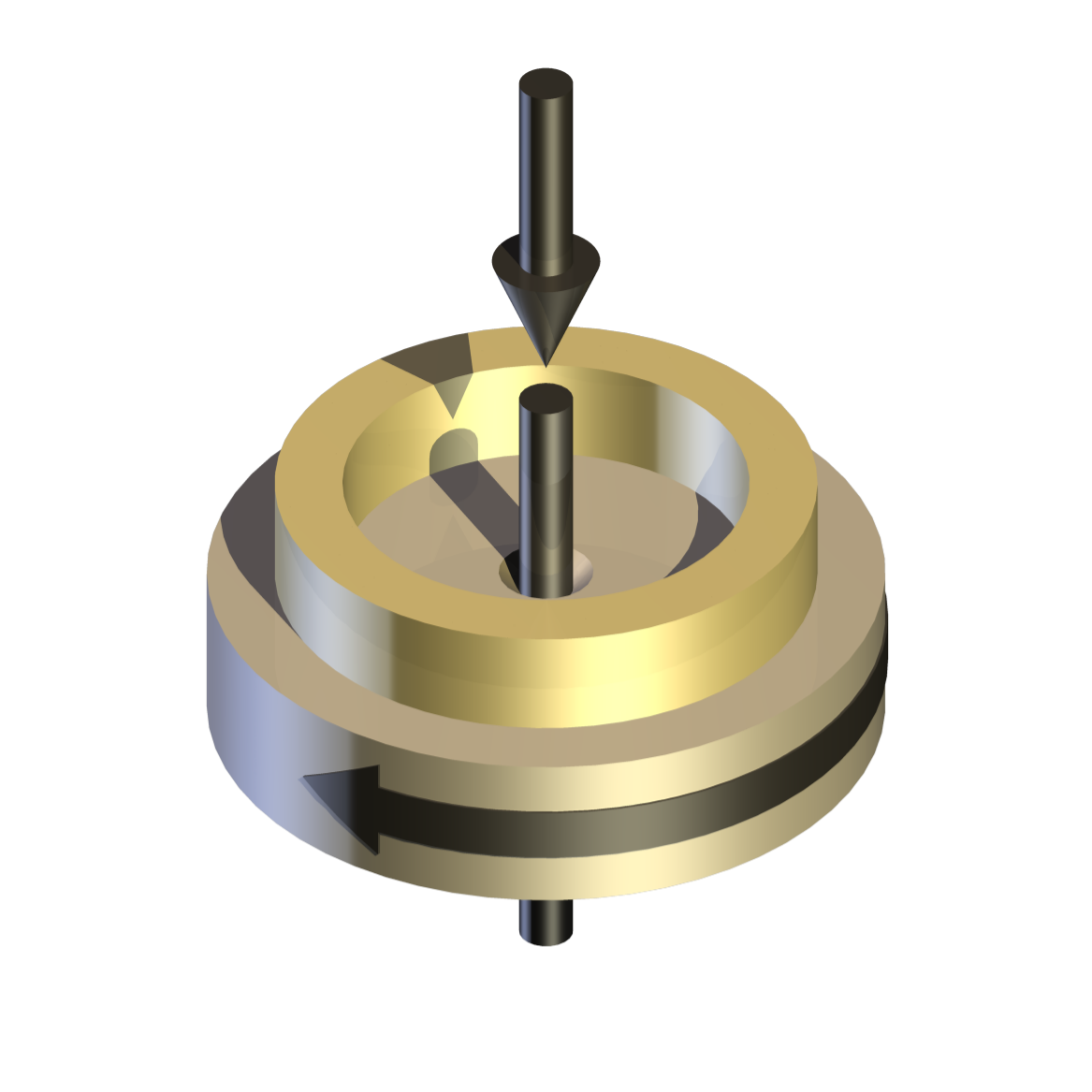

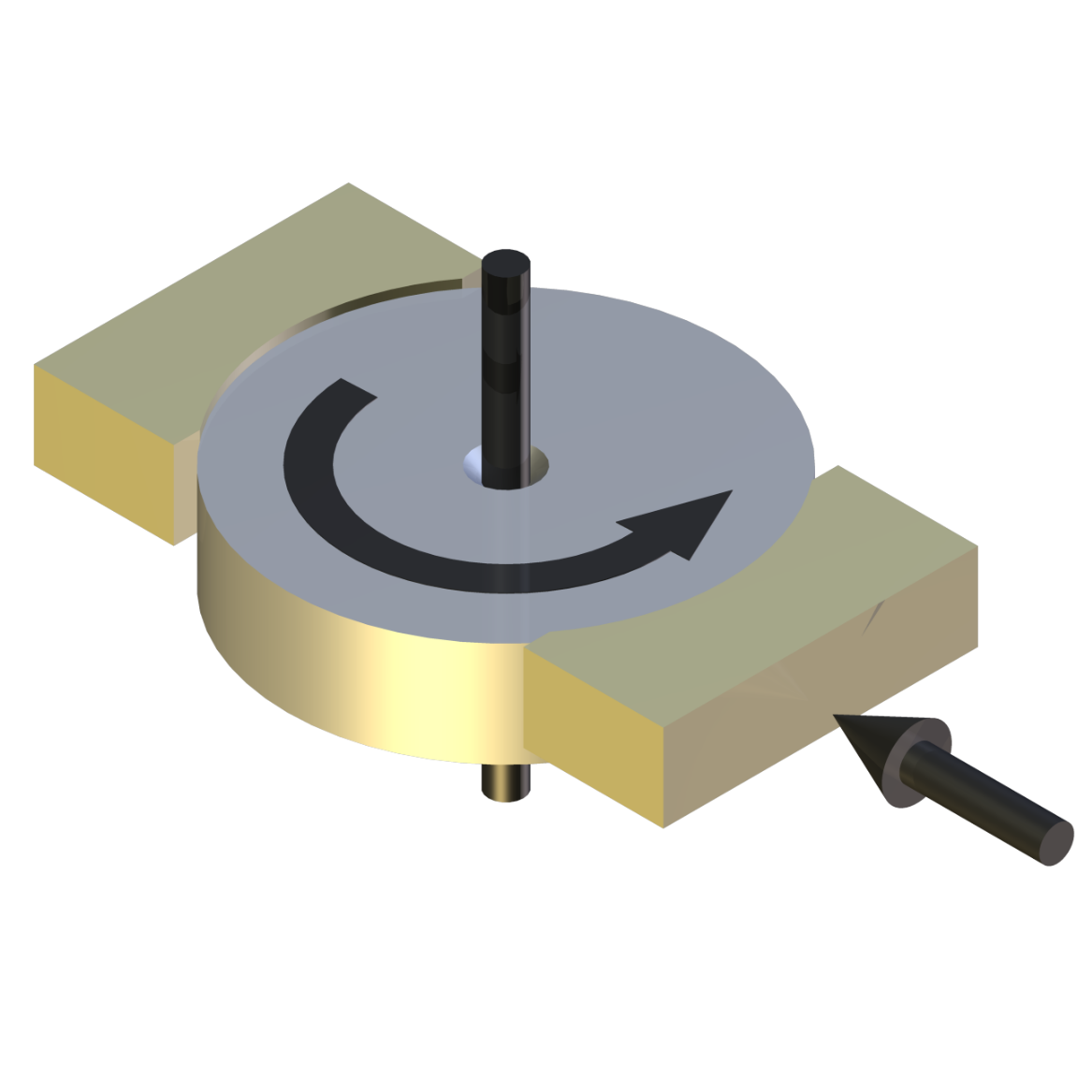

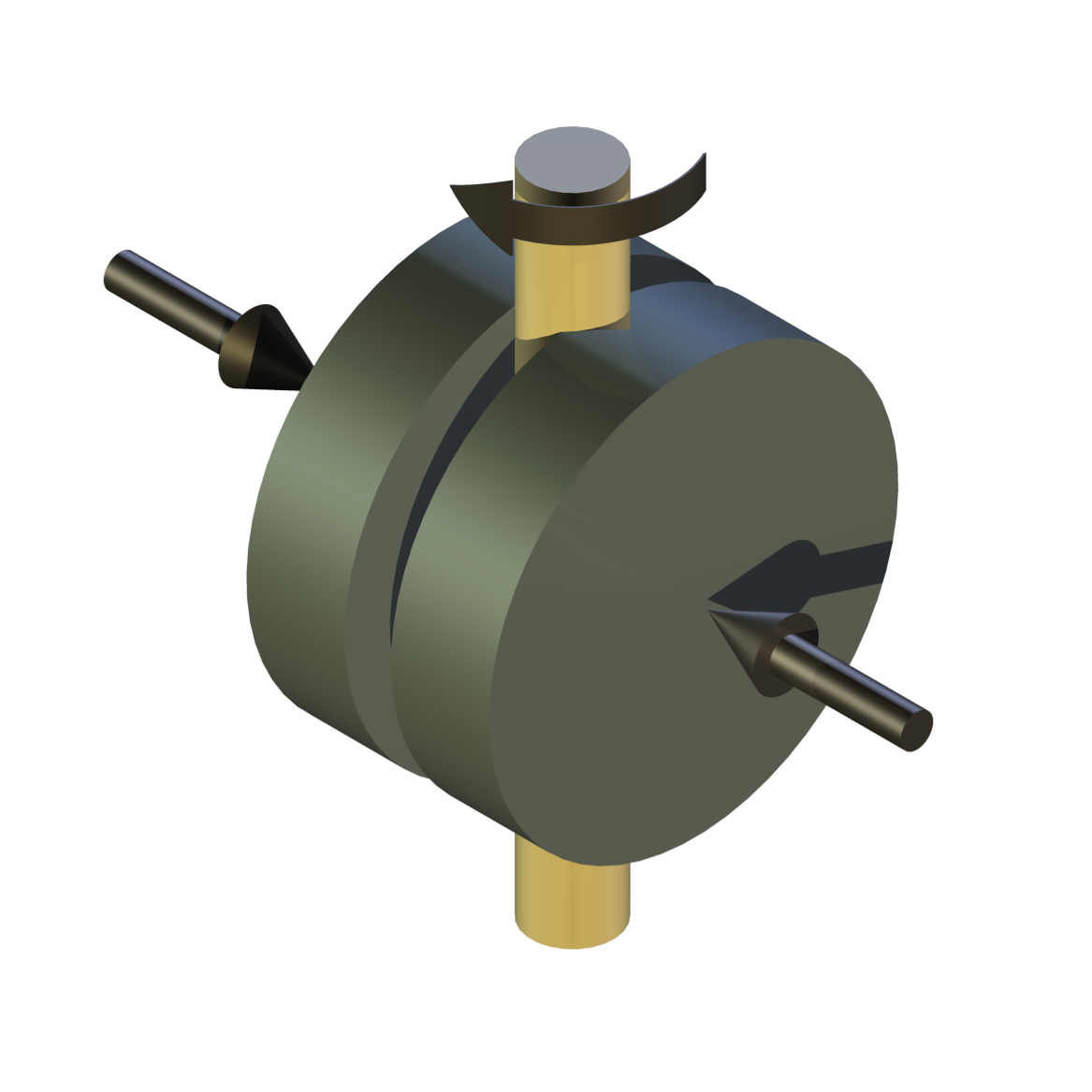

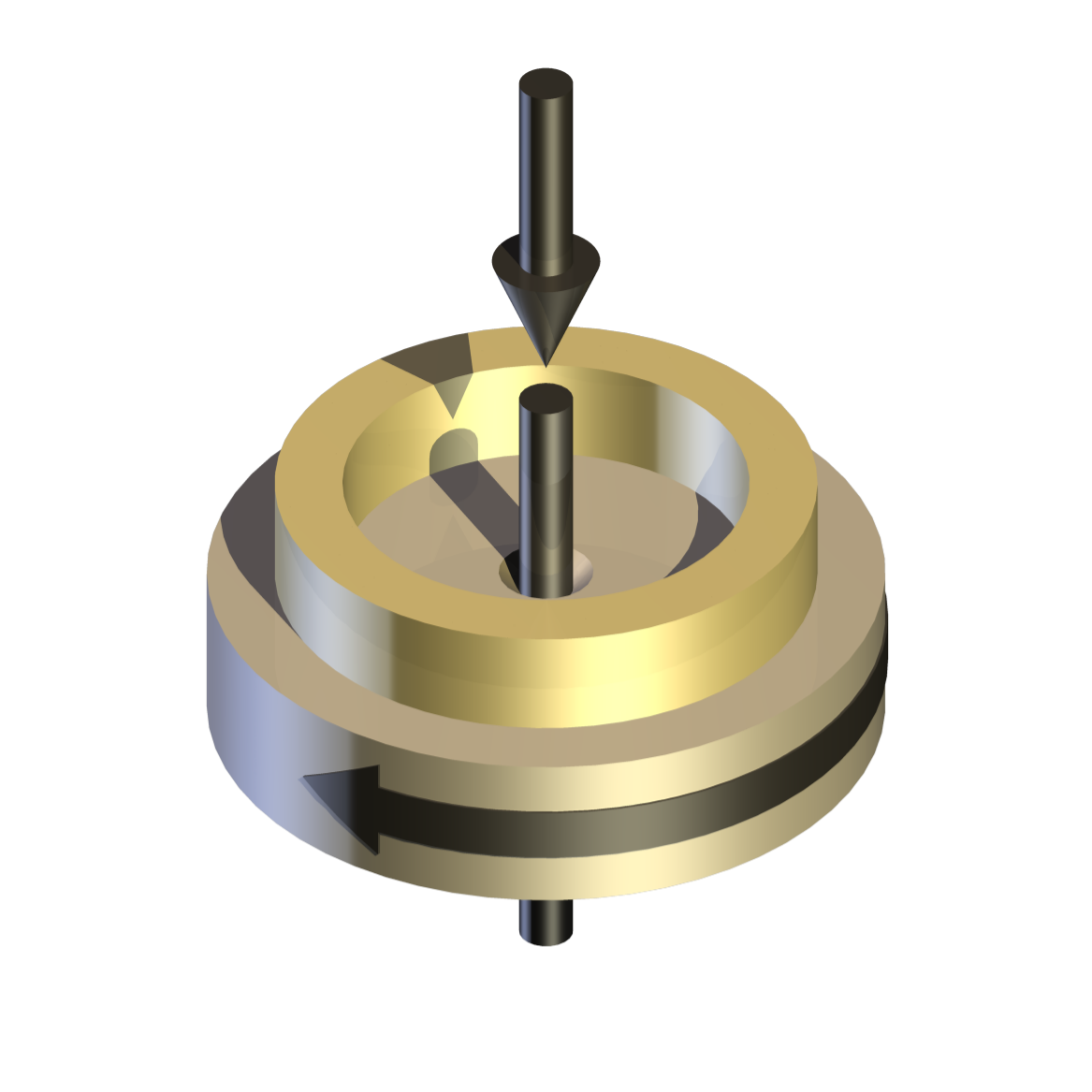

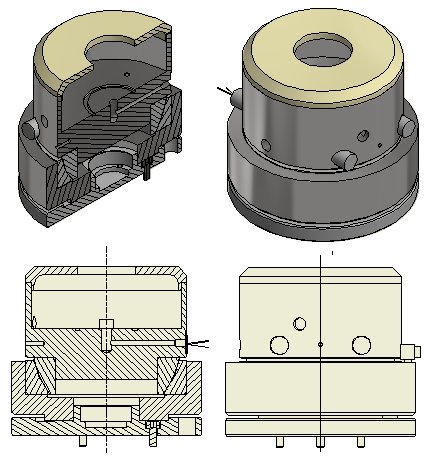

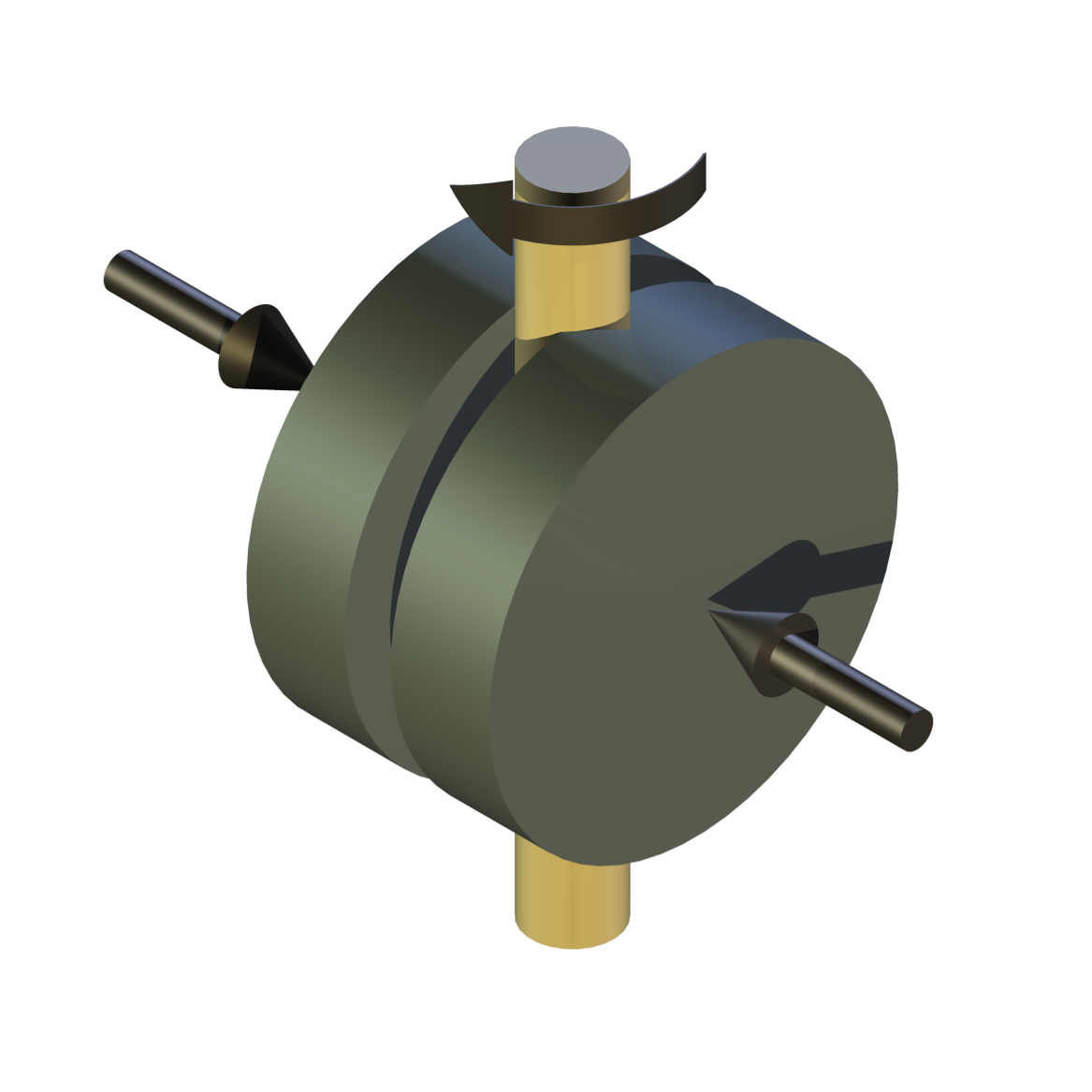

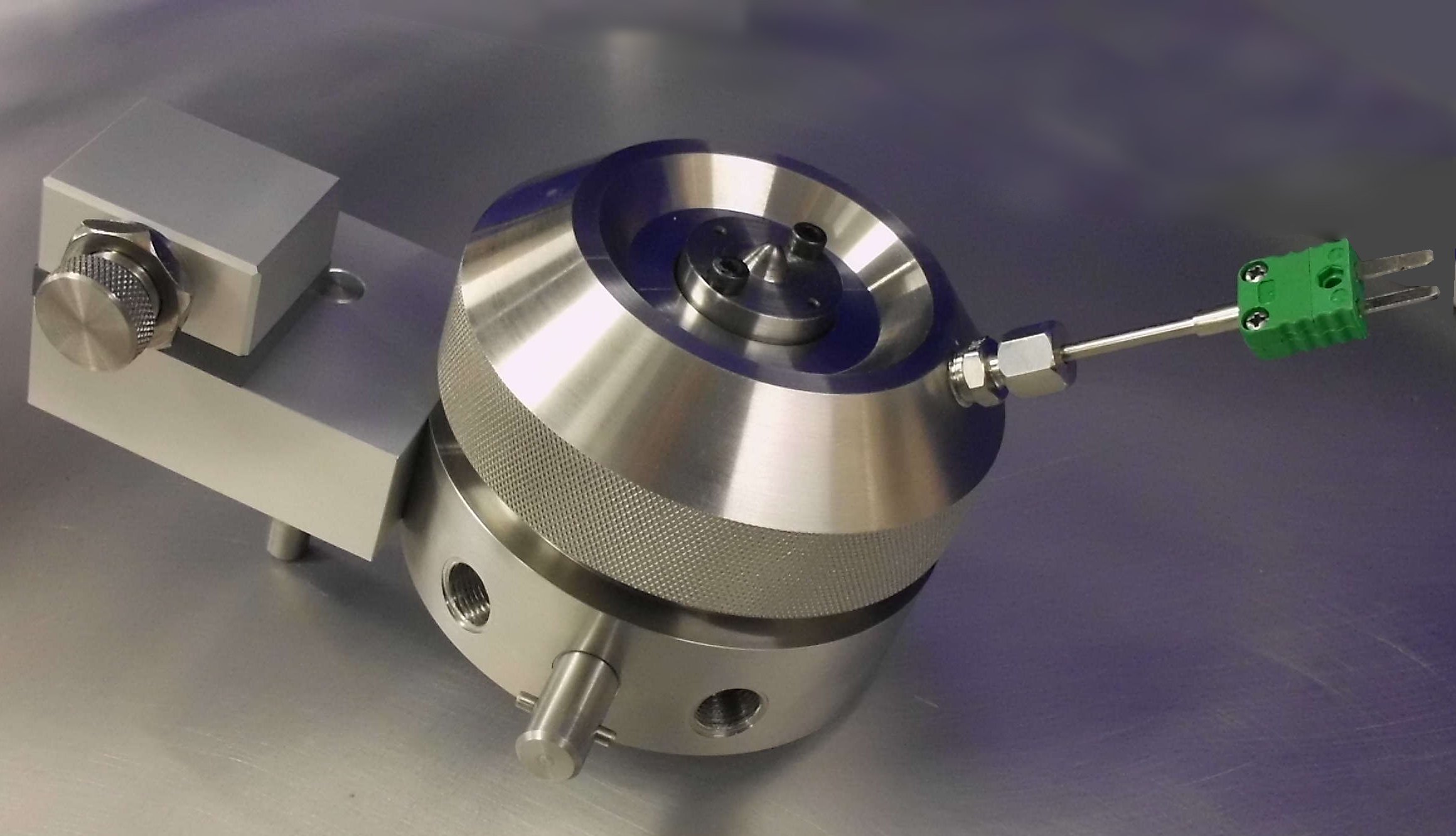

TE 92/SA/3 KRL Shear Test Adapter (DIN 51350 Part 6)

This adapter is used in conjunction with the TE 92/2 High Load Actuator to perform test in accordance with:

- • DIN 51350/6 Testing of Shear Stability of Lubricating Oils Containing Polymers

- • CEC L-45-A-99 Viscosity Shear Stability of Transmission Lubricants

The test assembly comprises a test reservoir, clamping nut, integral labyrinth for temperature control, torque arm and thermocouple sensor. The temperature of the lubricant is maintained at 60°C by means of a free-standing temperature-controlled water circulating system.

TE 92/SA/4 Cone on Elastomer Ring Test Adapter

This adapter is designed for testing the frictional properties of rubber materials for seals. A rotating steel cone is axially loaded against a ring made from rubber sheet. Tests can be either dry or lubricated.

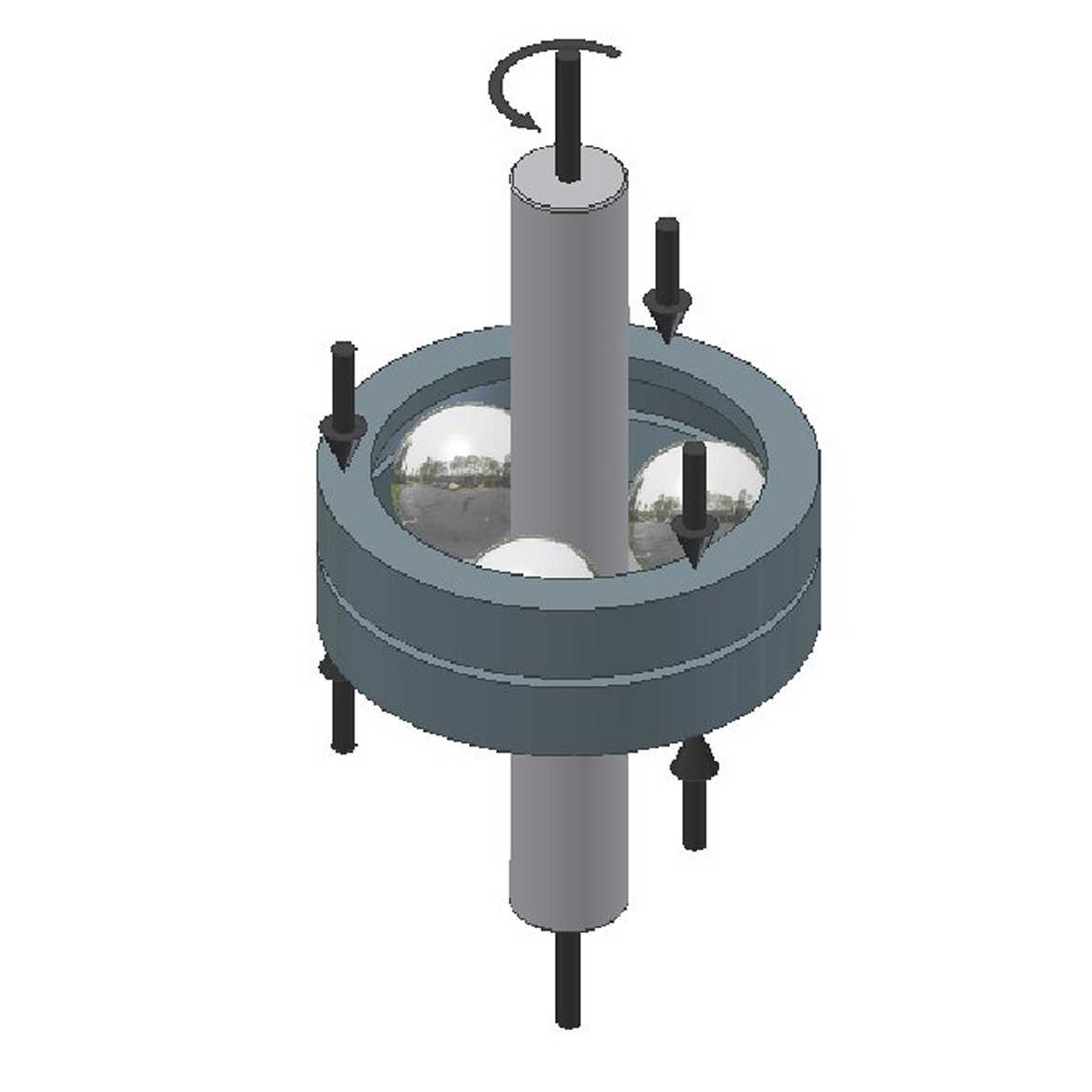

TE 92/SA/5 Orbital Spherical Bearing Test Adapter

This adapter applies an axial load to a spherical bearing seat, which is subjected to orbital, as opposed to rotary, motion. Such bearings include hip joints and spherical radial bearings, under certain operating conditions.

The device induces orbital motion and allows measurement of frictional torque about the leaning axis of the upper component. Torque about the vertical loading axis is also measured, on the lower component, however, this measurement is much less sensitive, especially when contact areas are small.

TE 92/SA/6 Lip Seal Friction Test Adapter

In this adapter, an upper chamber with a lip seal is rotated against a fixed shaft and the friction torque measured. The upper chamber is filled with lubricant and is thus the wet side of the seal. There are two advantages with the arrangement, firstly, thermocouples can be inserted into the non-rotating shaft to measure temperature of the material under the seal, secondly, it is easy to spot if and when the seal begins to leak.

The design can readily be adapted for different sized seals and shafts.

TE 92/O Oscillating Drive Adapter

The TE 92/O Oscillating Drive Adapter converts machine to oscillating. The angle of oscillation can be set between 0 and 90° with limits on the maximum frequency at large angles. The drive comprises a crank mechanism connecting the motor output shaft to the test spindle.

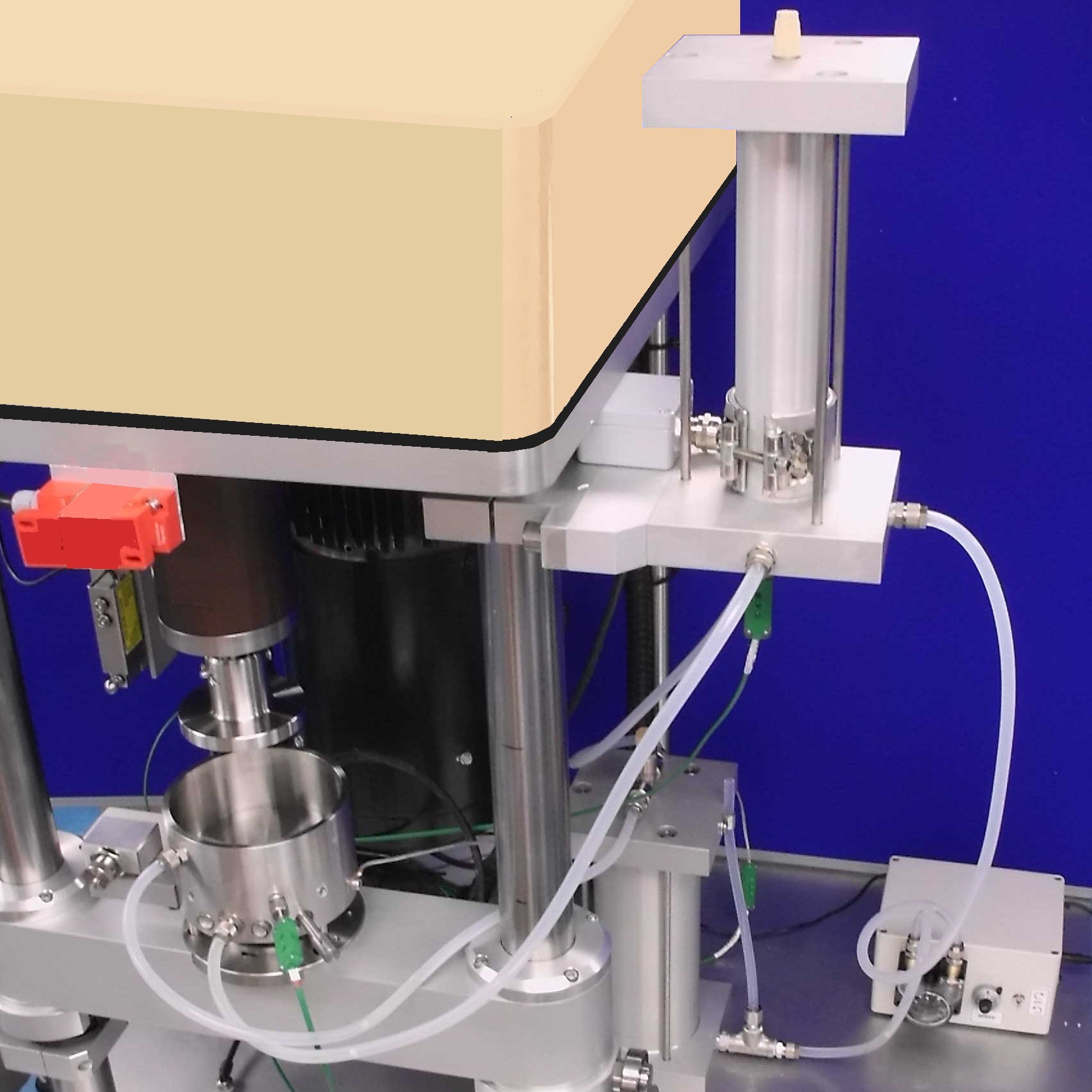

TE 92/LS Lubricant Re-circulating System

The system comprises a heated upper header tank, a lower sump tank and a peristaltic pump. The header tank is clamped to the right-hand machine column, which allows its height to be adjusted relative to the test assembly. Feed to the test adapter is by gravity, via a manual control valve and through a port which discharges in the centre of the adapter, with drain back to the sump tank, under gravity.

Fluid is pumped from the sump tank to the header tank, with entry at the bottom of the vessel. The fluid rises within the vessel until it reaches the level of an outlet stand-pipe. If inlet flow exceeds outlet flow, the level would continue to rise until it reaches the level of an overflow pipe, which then discharges back to the sump.

TE 92/CAL Calibration System

The TE 92/CAL provides facilities to calibrate Load, Torque and Temperature. A

load hanger and weights are provided for friction calibration, a reference load cell for load calibration and a thermocouple emulator for temperature calibration. -

Technical Specifications

TE 92 TE 92HS Rotational Speed: 30 to 3,000 rpm 30 to 3,000 rpm 60 to 6,000 rpm 100 to 10,000 rpm Spindle Bearing Load: 10,000 N @ 3,000 rpm 10,000 N @ 3,000 rpm 4,000 N @ 10,000 rpm Maximum Spindle Speed: 6,000 rpm 10,000 rpm Torque Capacity: 14 Nm @ 30 to 1500 rpm 14 Nm @ 30 to 1500 rpm 7 Nm @ 3,000 rpm 7 Nm @ 3,000 rpm 3.5 Nm @ 6,000 rpm 2.1 Nm @ 10,000 rpm Motor: 2.2 kW ac @ 1,500 rpm 2.2 kW ac @ 1,500 rpm 100% overload for 30 seconds 100% overload for 30 seconds Vibration Sensor: piezo-electric Contact Resistance: Lunn-Furey Circuit Interface: USB Serial Link Interface Module Software: COMPEND 2000 TE 92 + 4 kW Upgrade TE 92HS + 4 kW Upgrade Rotational Speed: 30 to 3,000 rpm 30 to 3,000 rpm 100 to 10,000 rpm Spindle Bearing Load: 10,000 N @ 3,000 rpm 10,000 N @ 3,000 rpm 4,000 N @ 10,000 rpm Maximum Spindle Speed: 6,000 rpm 10,000 rpm Torque Capacity: 25 Nm @ 30 to 1500 rpm 25 Nm @ 30 to 1500 rpm 13 Nm @ 3,000 rpm 13 Nm @ 3,000 rpm 4 Nm @ 10,000 rpm Motor: 4 kW ac @ 1,500 rpm 4 kW ac @ 1,500 rpm 100% overload for 30 seconds 100% overload for 30 seconds Controlled Parameters Rotational Speed Temperature Load Test Duration Recorded Parameters Rotational Speed Friction Torque Contact Resistance Temperatures Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance TE 92/1 Low Load Actuator Assembly Load Range: 20 to 1,000 N TE 92/2 High Load Actuator Assembly Load Range: 200 to 10,000 N TE 92/FOUR Heater Pad and Ball Collet for Four Ball Tests Ball Size: 12.7 mm (0.5″) Heater Block Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C TE 92/FOUR/1 Sliding Four Ball Test Assembly Ball Size: 12.7 mm (0.5″) Temperature Sensor: k-type thermocouple TE 92/FOUR/2 Rolling Four Ball Test Assembly Ball Size: 12.7 mm (0.5″) Temperature Sensor: k-type thermocouple TE 92/AREA-L Heated Test Bath & Shaft Hub for Lubricated Tests Reservoir Capacity: 500 ml Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C Compatible Tooling: TE 92/AREA/1,2,3,4,5 & 6 TE 92/AREA-D Specimen Mount with Capacitance Wear Sensor & Shaft Hub for Dry Tests Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C Resolution: 0.2 microns Compatible Tooling: TE 92/AREA/1 & 2 TE 92/AREA-H Specimen Mount & Shaft Hub for Dry Tests up to 600°C Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 600°C Compatible Tooling: TE 92/AREA/1 & 2 TE 92/AREA/1 Three Pin on Disc Tooling Contact Configuration: Rotating Disc on Three Pins Ball Specimen Diameter: 6 mm Mean Friction Diameter: 40, 50 & 60 mm Small Pin Diameter: 4 mm Mean Friction Diameter: 40, 50 & 60 mm Large Pin Diameter: 8 mm Mean Friction Diameter: 50 mm TE 92/AREA/2 ASTM D3702 Thrust Washer Specimen Tooling Contact Configuration: Thrust Washer 1.125″ O/D according to ASTM D 3702 2″ O/D according to ASTM D 3702 User specified non-standard TE 92/AREA/3 LVFA (small) Specimen Tooling Contact Configuration: Thrust Washer (LVFA small) Friction Sample Inner Diameter: 20 mm Friction Sample Outer Diameter: 26 mm Counter-face Outer Diameter: 37 mm TE 92/AREA/4 Vane Pump Specimen Tooling Contact Configuration: Three Vane on Disc Vane Width: 15.5 mm Vane Thickness: 2 mm Mean Friction Diameter: 31.5 mm Counter-face Outer Diameter: 50 mm TE 92/AREA/5 Suzuki Test Specimen Tooling Contact Configuration: Thrust Washer Rotating Sample Inner Diameter: 20 mm Rotating Sample Outer Diameter: 30 mm TE 92/AREA/6 Three Pad Thrust Bearing (Stribeck) Tooling Contact Configuration: Ring on Taper Land/Flat Land Pads Ring Internal Diameter: 60 mm Ring External Diameter: 92 mm Ring Thickness: 9 mm Taper Land Length: 5 mm Taper Land Width: 10 mm Taper Land Angle: 0.5 degrees Flat Land Length: 5 mm Flat Land Width: 10 mm User specified non-standard TE 92/RCF Self-aligning Heated Reservoir for Rolling Contact Fatigue Tests Reservoir Capacity: 500 ml Heater Power: 550 W Temperature Sensor: k-type thermocouple Maximum Temperature: 200°C Compatible Tooling: TE 92/RCF/1,2 & 3 TE 92/RCF/1 Cone on Angular Contact Bearing Tooling Contact Configuration: Cone on ball race – pure rolling Cone: 40 degree included angle Rolling Bearing: SKF 7206 cage and lower race Balls: silicon nitride Maximum Contact Stress: 5.5 GPa Maximum Speed: 3,000 rpm (TE 92) 10,000 rpm (TE 92HS) TE 92/RCF/2 Ball Thrust Bearing on Disc Tooling Thrust Bearing: Size 51208 Disc Diameter: 68 mm Maximum Speed: 6,000 rpm TE 92/RCF/3 Roller Thrust Bearing on Disc Tooling Thrust Bearing: Size 81208 TN Disc Diameter: 68 mm Maximum Speed: 6,000 rpm TE 92/RCF/E Electrical Discharge Machining (EDM) Test System Applied Voltage: 0 to 24 volts Cummutator: 2 pulses per revolution TE 92/RCF/2/E Ball Thrust Bearing Tooling for EDM Tests Thrust Bearing: Size 51208 Maximum Speed: 6,000 rpm TE 92/RCF/3/E Roller Thrust Bearing Tooling for EDM Tests Thrust Bearing: Size 81208 TN Maximum Speed: 6,000 rpm TE 92/RCF/T10 In-line Rolling Friction Torque Transducer Axial Load: 1 kN Torque: 10 Nm TE 92/RCF/T25 In-line Rolling Friction Torque Transducer Axial Load: 2.5 kN Torque: 25 Nm TE 92/RCF/T50 In-line Rolling Friction Torque Transducer Axial Load: 5 kN Torque: 50 Nm TE 92/RCF/T100 In-line Rolling Friction Torque Transducer Axial Load: 10 kN Torque: 100 Nm TE 92/PV Pin on Vee Block/Block on Ring Adapter Contact Configuration: Pin on vee block Block on ring User specified custom tooling Pin on Vee Specimens: Standard Falex specimens Ring Specimen: Max dia 35 mm x max width 10 mm Maximum Load: 20,000 N Rotational Speed: 60 to 1,840 rpm (direct drive) 60 to 3,000 rpm (direct drive) Torque Capacity: 7.4 Nm @ 60 to 1,840 rpm (direct drive) 4.5 Nm @ 3,000 rpm (direct drive) Heater Bath Temperature: 200 °C TE 92/LL Precision Low Load Adapter Load Range: 1 to 1,000 N TE 92/EC Electro-chemical Cell & Potentiostat Contact Configuration: Three balls rotating on fixed disc Contact Configuration: Three pins rotating on fixed disc Load Range: 1 to 1,000 N Potentiostat: Ref 600 Potentiostat/Galvanostat/ZRA TE 92/SA/1 Special Adapter – Three Station Ring on Liner Adapter Contact Configuration: Line Contact Maximum Ring Sample Load: 500 N Maximum Liner Surface Temperature: 200 °C TE 92/SA/2 Special Adapter – Three Ball on Rod Rolling Contact Fatigue Standard Ball Diameter: 12.7 mm (1/2 inch) Standard Rod Diameter: 9.52 mm (3/8 inch) Cone Included Angle: 45 degrees Stress Cycles: 2.3828 per revolution Maximum Contact Pressure (steel on steel): 5.5 GPa TE 92/SA/3 Special Adapter – KRL Shear Test Adapter (DIN 51350 Part 6) Bearing: SKF 32008 X/Q Temperature Sensor: k-type thermocouple Sump Capacity: 35 litres Heater Power: 3 kW Pump Flow: 9 litre/minute at zero head TE 92/SA/4 Cone on Elastomer Ring Test Adapter Cone Angle: 45 degrees Ring Internal Diameter: 42 mm Ring Outside Diameter: 70 mm Ring Thickness: 6 mm TE 92/SA/5 Orbital Spherical Bearing Test Adapter Maximum Ball Diameter: 50 mm Maximum machine axial load: 10 kN Maximum Tilt Angle: 15° Maximum Speed: 120 rpm TE 92/SA/6 Lip Seal Friction Test Adapter User Specified Lip Seal Inner Diameter: 38 to 68 mm TE 92/LS Circulating Lubricant Supply up to 100°C Header Tank Volume: 1.2 litres Peristaltic Pump Flow: 1 litre/minute (maximum) Heating Power: 550 W Temperature Range: ambient to 100°C TE 92/0 Oscillating Drive Adapter Oscillating Motion: +/-10 degrees at 25 Hz +/-15 degrees at 20 Hz +/-20 degrees at 18 Hz +/-25 degrees at 15 Hz +/-35 degrees at 10 Hz +/-45 degrees at 8 Hz TE 92/HSD High Speed Data Acquisition Option High Speed Interface: USB Resolution: 16 bit Number of Input Channels: 6 Maximum Data Rate: Six channels at 50 kHz TE 92/DM Digital Microscope with Camera & PC Image Capture Software Magnification: x 40 Graticule: range 2 mm with 0.01 mm divisions range 4 mm with 0.02 mm divisions Services Electricity – TE 92 & TE 92HS 220/240V, single phase, 220/240V, single phase, 50/60 Hz, 7.5 kW 50/60 Hz, 7.5 kW Electricity – TE 92 & TE 92HS + 4 kW Upgrade 380/415 V, three phase, 380/415 V, three phase, 50/60 Hz, with neutral & earth 7.5 kW 50/60 Hz, with neutral & earth 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) 4 cfm at 8 bar (120 psi) Installation Floor-standing machine: 900 mm x 600 mm deep x 2000 mm 350 kg Packing Specifications: 2.2 m3, GW 550 kg -

Applications

-

Overview Videos

Machine Overview

EDM Tests

Training Videos

TE 92 Machine Training Video

Pin On Vee Adaptor Training Video

TE92/RCF/E EMD Tooling Training Video

-