-

Description

The TE 82 has manually controlled pneumatic loading and PLC controlled motor with encoder feedback. The machine is floor-standing. The drive motor is connected to the test spindle by a timing belt and torque limiter pulley. Pre-programmed tests sequences are provided for running the following test procedures:

• ASTM D2266 Wear Preventive Characteristics of Lubricating Greases

•ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid

•ASTM D2596 Extreme Pressure Properties of Lubricating Greases

•ASTM D2783 Extreme Pressure Properties of Lubricating Fluid

•IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants

•DIN 51350/1-5 Testing Lubricants: Testing in the Shell Four-Ball TesterWith TE 82/KRL Adapter and TE 82/SM Temperature Control Service Module

•DIN 51350/6 Testing of Shear Stability of Lubricating Oils Containing Polymers

•CEC L-45-A-99 Viscosity Shear Stability of Transmission Lubricants

•ISO 26422:2014 Determination of shear stability of lubricating oils containing polymers

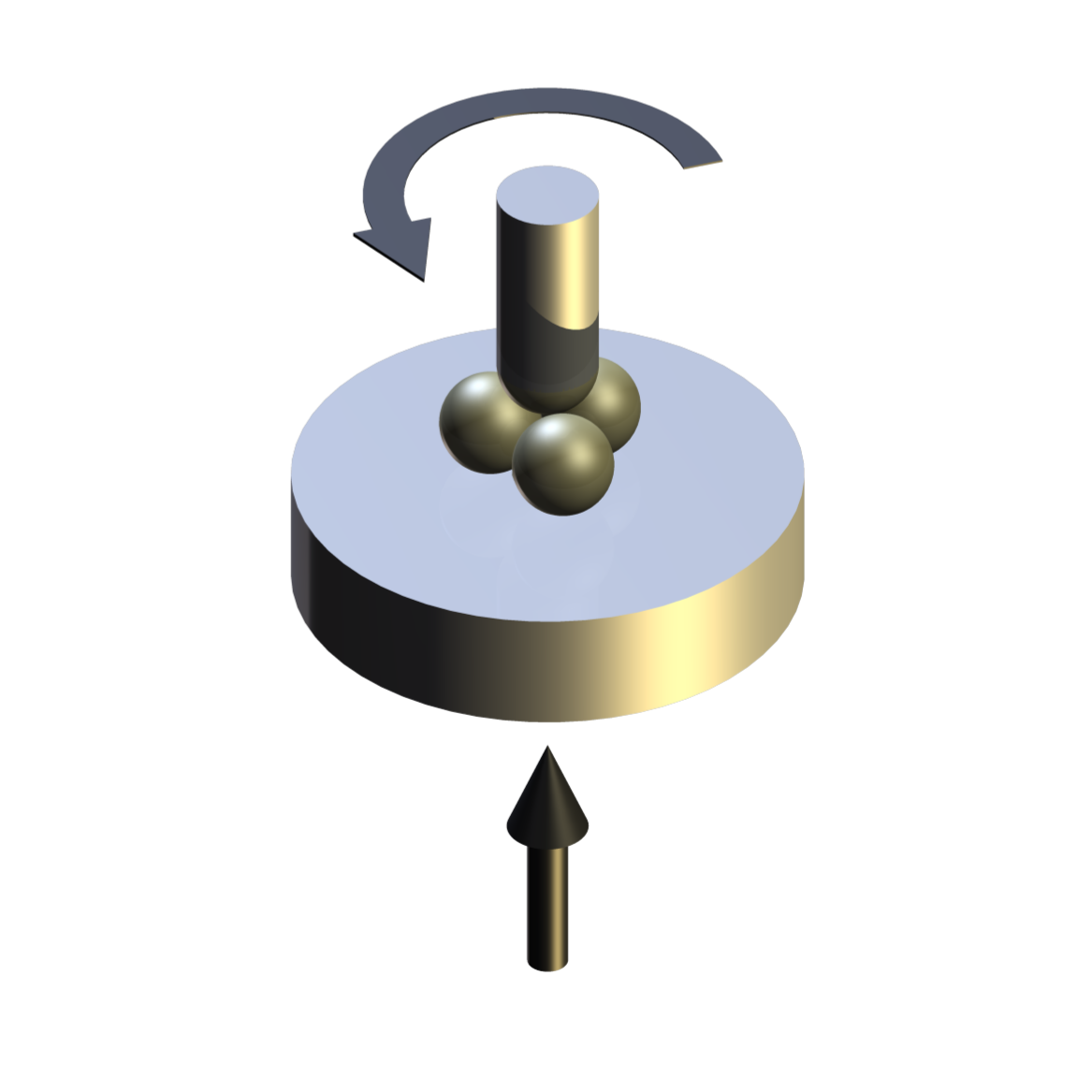

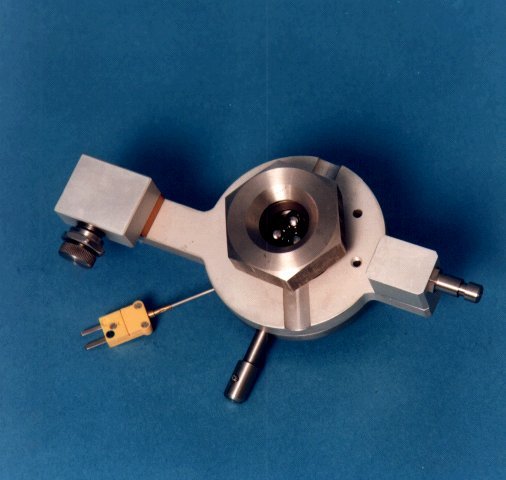

The TE 82 includes the test adapter for both wear and extreme pressure sliding four ball tests. This comprises a test reservoir, clamping nut, thrust face and clamping ring for the three test balls, integral torque arm and thermocouple sensor.

Optional Accessories

TE 82/DM Digital Microscope with Camera & PC Image Capture Software

The test assembly is also designed to locate on the TE 82/DM to allow post-test measurement of wear scars, without having to removing the balls from the test adapter, which fits onto the base of the microscope assembly. The microscope is located on angled holder, set to the standard contact angle of the test balls. This means that the microscope is normal to the wear scar.

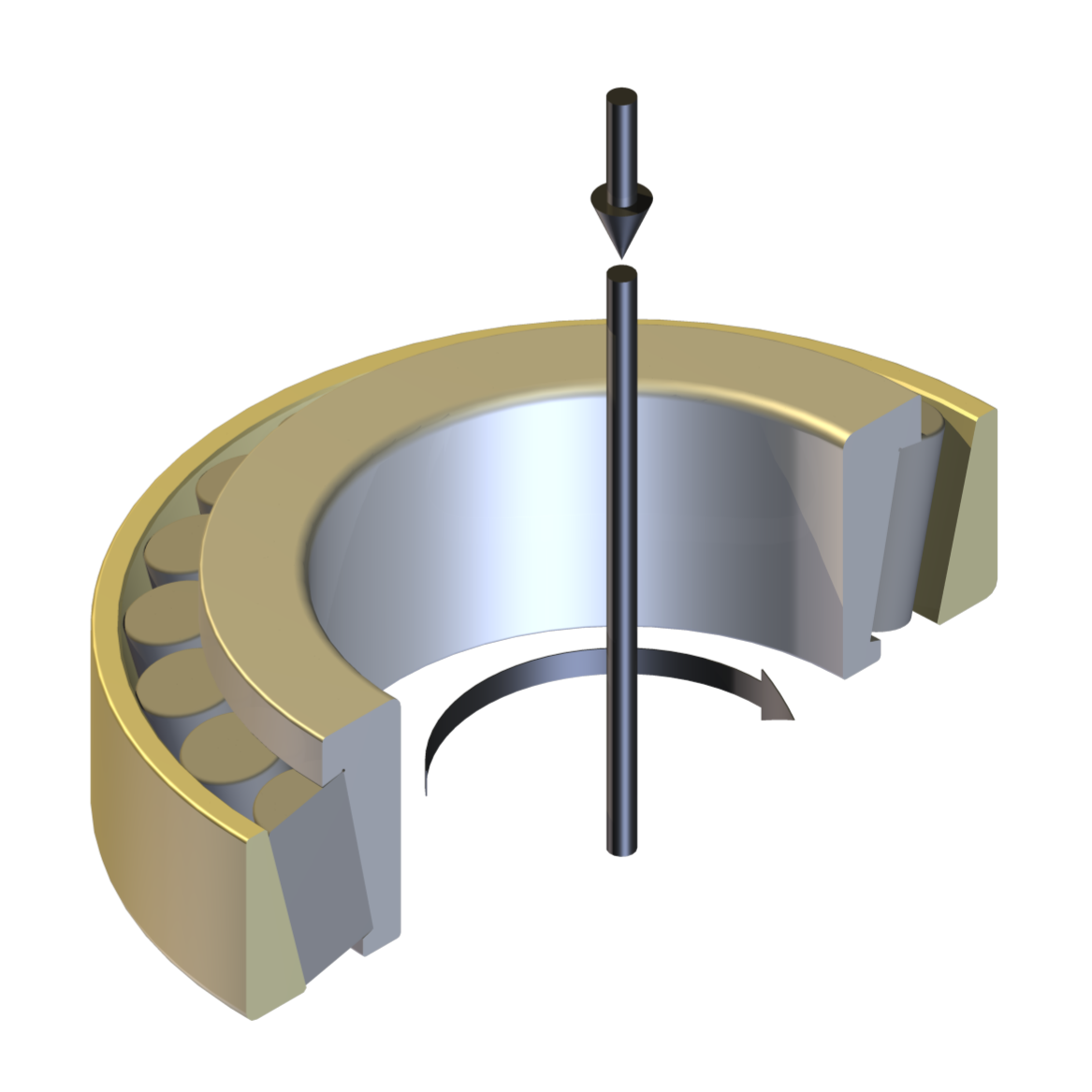

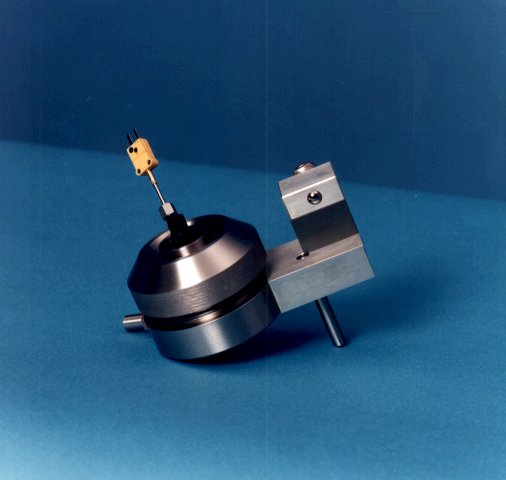

TE 82/KRL Shear Stability Test Adapter

The DIN 51350-6 and CEC test methods are for the determination of the shear stability of lubricating oils with polymer additives. The test assembly comprises a test reservoir, clamping nut, integral labyrinth for temperature control, torque arm and thermocouple sensor.

The temperature of the lubricant is maintained at 60°C by means of the TE 82/SM Temperature Control Service Module, which is a free-standing temperature-controlled water circulating system.Control and Data Acquisition

Speed set-point control is manual, implemented via a PLC, with inputs via touch-screen. Data is recorded at 10 Hz sampling rate, stored by the PLC and exported on USB stick, for post-processing.

-

Technical Specifications

Size of Test Balls: 12.7 mm (0.5″) diameter Load Range: 10 to 10,000 N Loading Method: Pneumatic Load Ranges: 20 to 1,000 N 50 to 8,000 N Load Measurement: Pressure transducer Load Control: Precision pressure regulator Friction Measurement: Databeam strain gauge transducer Torque Reaction Mounting: Air bearing Rotational Speed: 60 to 1,800 rpm Temperature Range: Ambient to 200°C Heater Power: 550 W Temperature Sensor: k-type thermocouple Motor: 1.5 kW a.c. vector motor Control: PLC Data Acquisition Rate: 10 Hz Data Export: USB Stick Pre-programmed Test Sequences ASTM D2266 Wear Preventive Characteristics of Lubricating Greases ASTM D4172 Wear Preventive Characteristics of Lubricating Fluid ASTM D2596 Extreme Pressure Properties of Lubricating Greases ASTM D2783 Extreme Pressure Properties of Lubricating Fluid IP 239 Extreme Pressure Properties: Friction and Wear Test for Lubricants DIN 51350/1-5 Testing Lubricants: Testing in the Shell Four-Ball Tester Automatically Controlled Parameters Rotational Speed Temperature Test Duration Manually Controlled Parameters Load Measured Parameters Rotational Speed Load Friction Torque Temperature Test Duration Friction Coefficient Services Electricity: 220/240V, single phase, 50/60 Hz, 3.0 kW Clean, dry air: 4 cfm at 8 bar (120 psi) Installation Floor-standing machine: 900 x 670 deep x 2000 mm high, 300 kg Packing Specifications: 2.2 m3, GW 600 kg, NW 450 kg -

Download the Machine Leaflet