-

Description

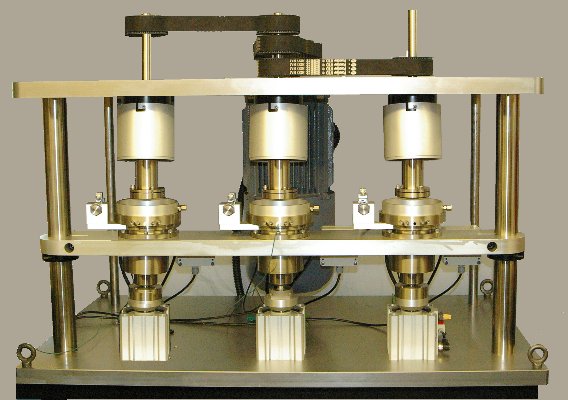

TE 94 Multi Station Rotary Tribometer is a three station test machine specifically designed to run multiple tests in the thrust washer and three pin on disc test configurations under identical test conditions. Sensors may be provided for on-line measurement of friction, wear displacement (by capacitance probe) and sample temperature.

The incorporation of a linear air bushing in the loading and friction torque assembly allows precise control of the load in the range control of load, range 20 to 2,000 N and corresponding precision in the measurement of friction torque.

Load is applied to each test station by means of pneumatic cylinders, with the same air pressure applied to each cylinder. One cylinder is designated as master and is fitted with a force transducer to measure the resulting specimen load. Pressure to the cylinders is manually controlled by means of a precision pressure regulator. Alternatively, automatic control can be implemented using an optional servo pneumatic control valve.

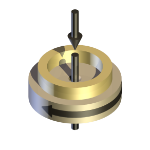

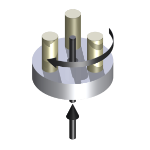

Tests may be run in accordance with the guidelines laid out in ASTM G99 Wear Testing with a Pin-on-Disc Apparatus and ASTM D3702 Standard Test Method for Wear Rate of Materials in Self-Lubricated Rubbing Contact Using a Thrust Washer Testing Machine.Control and Data Acquisition

Control and data acquisition are implemented via host PC running COMPEND 2020 Windows compatible software, in conjunction with a Phoenix Tribology USB micro-controller interface.

Automatic control is implemented via user programmable test sequences. Manual control is implemented using on screen toggles. Data is stored to hard disc in either .csv or .tsv file formats. -

Technical Specifications

Thrust Washer: According to ASTM D 3702 Pin Track Radius: 10 to 35 mm Pin Size: 8 mm diameter x 15 mm long Disc Diameter: 75 mm maximum Rotational Speed: 30 to 3,000 rpm Load Range: 20 to 2,000 N Maximum Temperature: 200°C Wear Measurement Resolution: 0.2 microns Motor: 2.2 kW a.c. vector motor Interface: Phoenix Tribology USB micro-controller interface Software: COMPEND 2020 Controlled Parameters Rotational Speed Load Temperature Test Duration Measured Parameters Rotational Speed Wear (Master plus Slaves Optional) Friction Force (Master plus Slaves Optional) Temperature Number of Revolutions Test Duration Sliding Speed Friction Coefficient Sliding Distance Services Electricity: 220/240V, single phase, 50 Hz, 7.5 kW 110/120 V, single phase, 60 Hz, 7.5 kW Clean, dry air: 4 cfm at 8 bar (120 psi) -

Applications

friction materials multi-station oscillating contact pin on disc plastics polymers PV diagrams self-lubricating materials thrust washer -

User List

Launched 2008

Wittenburg b.v. Netherlands Evonik Industries, Degusa Germany -

Download the Machine Leaflet